Lamination technology of precise circuit board

A circuit board and precision technology, which is applied in the field of precision circuit board lamination technology, can solve the problems of affecting the line width accuracy of the circuit board and large side erosion of the circuit, so as to reduce the amount of side erosion of the circuit, reduce the etching time, and ensure the accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

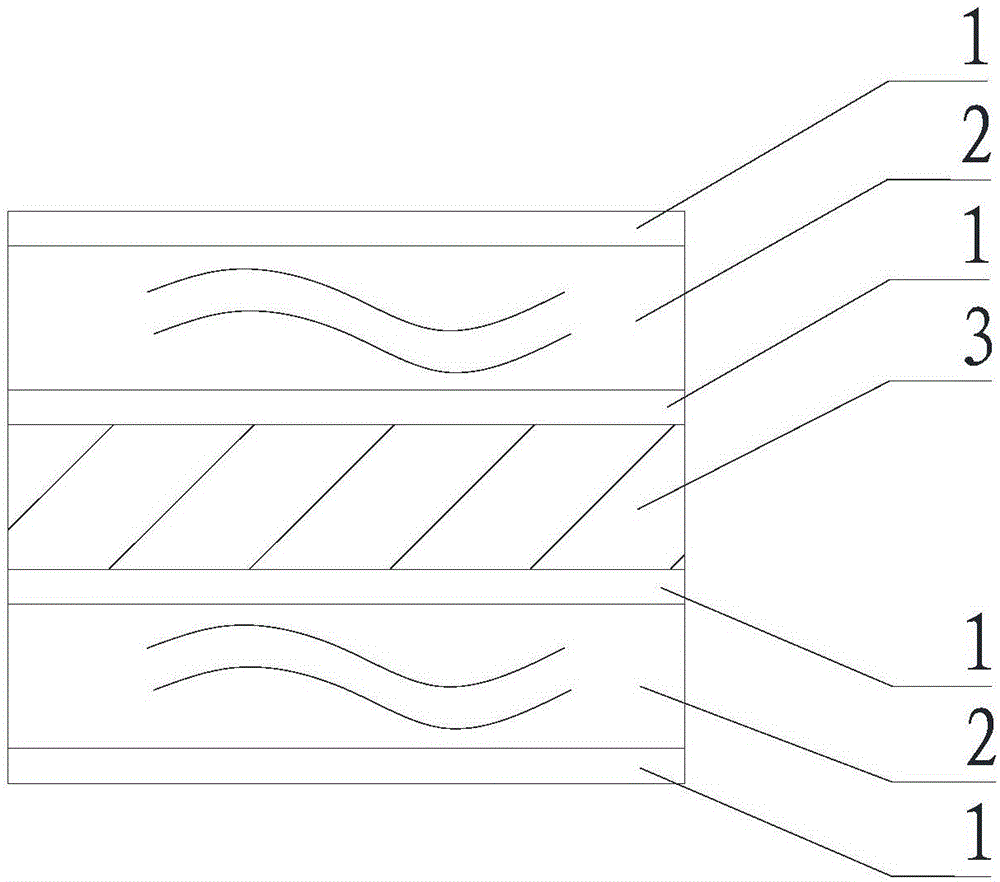

Embodiment 1

[0028] Before the step S1, browning treatment on the core board and the lower surface is also included. The browning treatment of the core board is to make the combination of the core board and the prepreg stronger.

Embodiment 2

[0030] After a large number of tests and verifications, when the thickness of the browning film (that is, the contour) is 2-4 microns, the tensile force between the copper foil and the prepreg can be guaranteed to be above 4lb / inch, and a firm bonding effect between the copper foil and the prepreg can be achieved. .

Embodiment 3

[0032] In the step S2, the rough side of the copper foil faces outward, and the smooth side faces the prepreg. The profile of the smooth surface of the copper foil after browning (2-4 microns) is smaller than the profile of the rough surface of the copper foil (8-10 microns), so it can effectively reduce the depth of the copper foil entering the prepreg, making the circuit board easier to etch. The etching time is relatively reduced, and the side etching amount of the circuit is also relatively reduced, thereby ensuring the accuracy of the line width of the circuit board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com