Microstructured multicore optical fibre (mmof), a device and the fabrication method of a device for independent addressing of the cores of microstructured multicore optical fibre

A microstructured, multi-core technology, applied in the field of device manufacturing, which can solve problems such as crosstalk and bending loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I

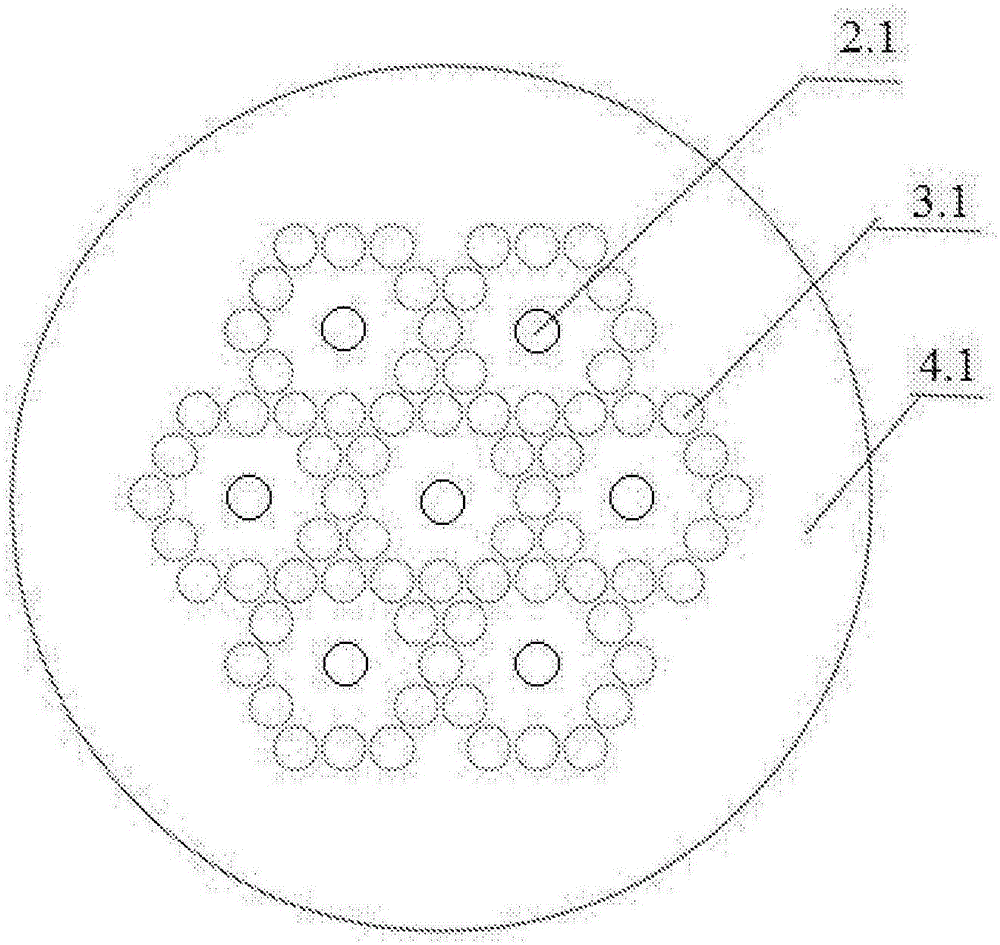

[0062] Microstructured multi-core optical fiber according to the invention and intended for transmission, further, the microstructured multi-core guide fiber according to the invention comprises regions with microstructures in which base units are embedded, each of them comprising A core of doped silica glass, around which are longitudinal pores filled with air, (further, said pores) located in a matrix of silica glass.

[0063] For a light wavelength of λ = 1550 nm, the difference between the refractive indices of the core material and cladding (outer and inner) corresponds to Δ = 5.2 10 -3 ±0.5·10 -3 .

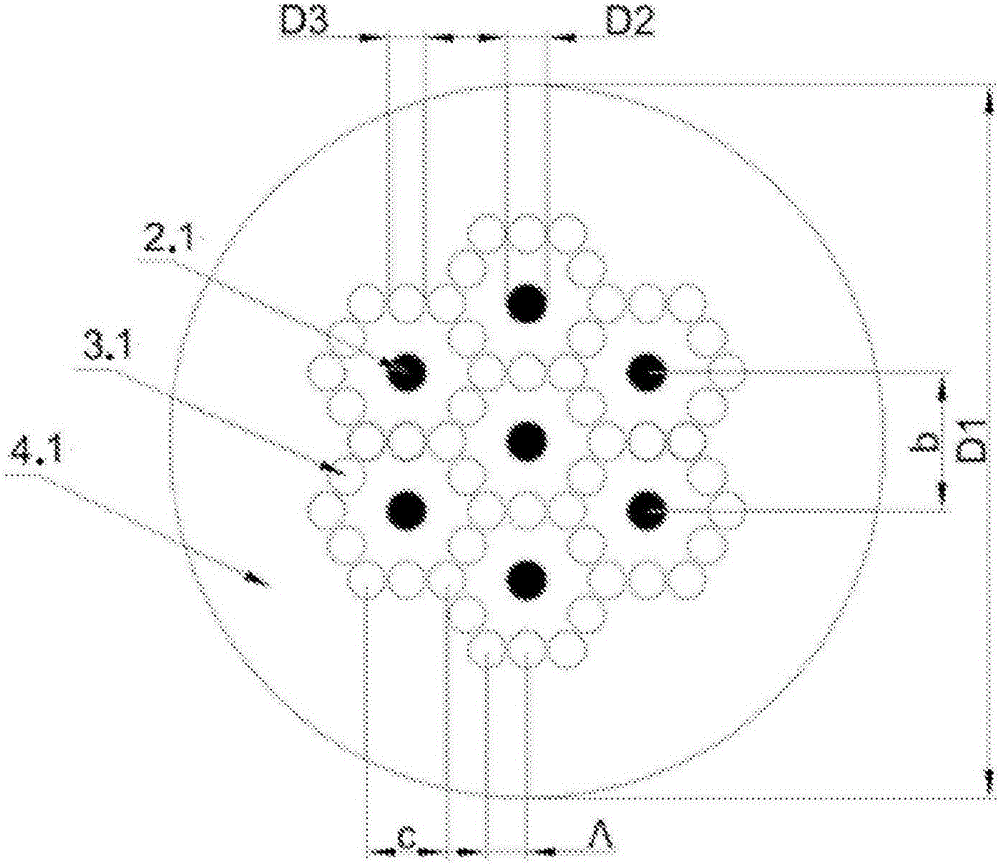

[0064] The base unit is characterized by a D2 core diameter, a D3 pore diameter and a lattice constant Λ corresponding to the distance between the centers of adjacent pores. The center of the hole is positioned on the vertices and midpoints of the sides of the hexagon, the center of which is represented by the core; the length of the side c of the hexagon formed by the axi...

example II

[0103] The microstructured multi-core optical fiber according to the invention comprises microstructured regions in which are embedded fundamental units, each of them comprising a core of doped silica glass with air-filled longitudinal holes surrounding it , (further, the pores) are located in a matrix of silica glass.

[0104] For a light wavelength of λ = 1550 nm, the difference between the refractive indices of the core material and cladding (outer and inner) corresponds to Δ = 5.2 10 -3 ±0.5·10 -3 .

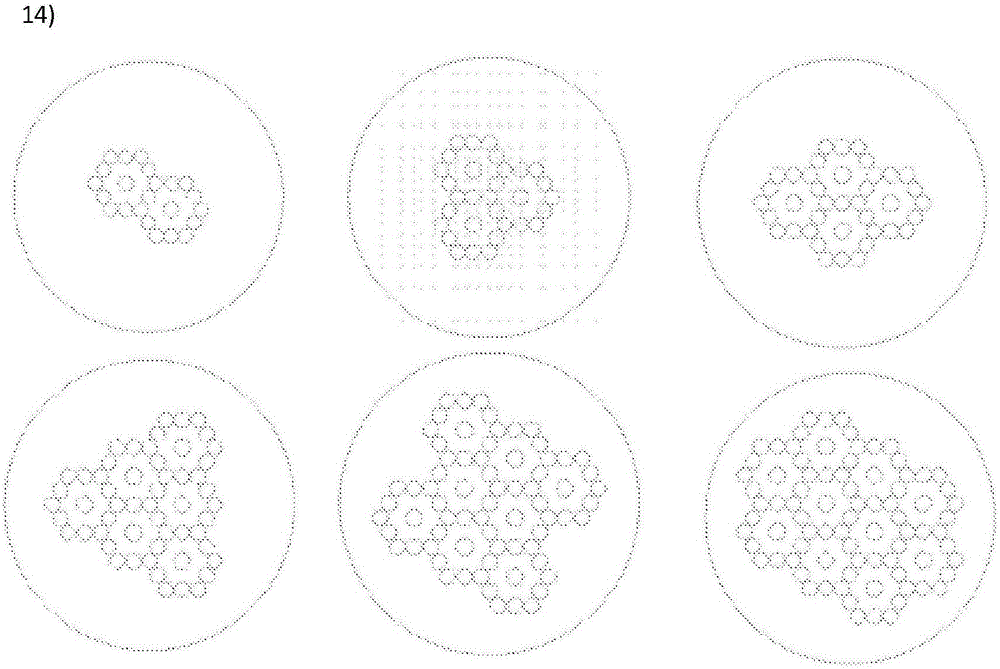

[0105] The base unit is characterized by a D2 core diameter, a D3 pore diameter and a lattice constant Λ corresponding to the distance between the centers of adjacent pores. The center of the hole is positioned on the vertices and midpoints of the sides of the hexagon, the center of which is represented by the core; the length of the side c of the hexagon formed by the axis of the hole is equal to twice the lattice constant Λ. The base units juxtaposed within the microstru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com