Method and device for continuously preparing high-concentration ozone water

A high-concentration ozone water technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of restricting the application of high-concentration ozone water and low solubility, and achieve low equipment cost, high concentration and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

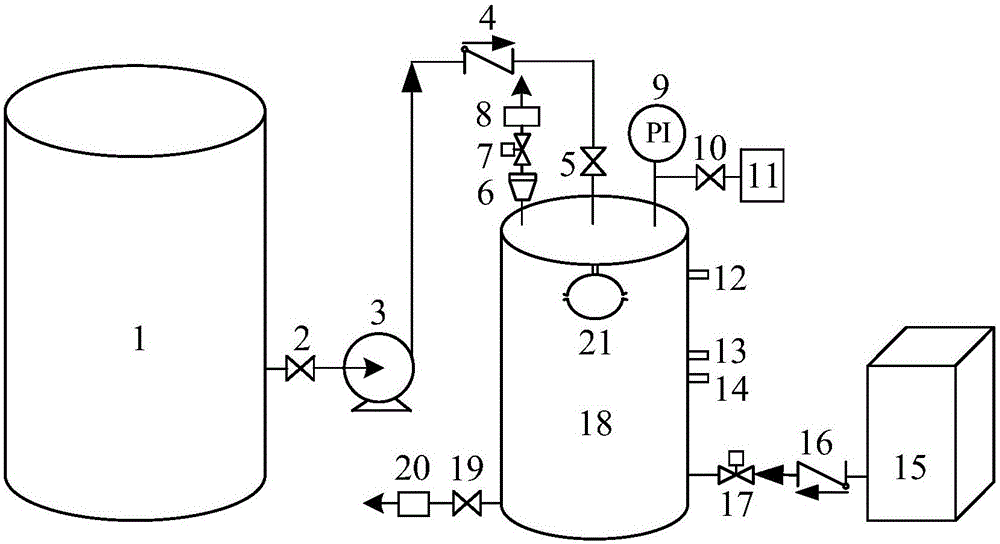

[0047] In this embodiment, high-concentration ozone water is prepared by dissolving ozone gas under 1 atmospheric pressure in the tank.

[0048] Install a water storage tank valve on the water storage tank and connect it with the booster pump inlet. Install a water inlet check valve at the outlet of the booster pump, install a water inlet valve on the ozone water generating tank, and connect the two valves to prevent the water in the tank from flowing back from the water inlet. An elliptical rotary nozzle is installed in the ozone water generating tank and connected with the water inlet valve on the tank. The volume of the ozone water generating tank is 10L.

[0049] Install a pressure vacuum gauge on the ozone water generating tank to measure the vacuum degree and gauge pressure in the tank. A vacuum valve is installed on the ozone water generating tank and connected with a vacuum pump for vacuumizing the inside of the tank. An ozone inlet valve is installed at the lower p...

Embodiment 2

[0055] In this embodiment, high-concentration ozone water is prepared by dissolving ozone gas under 2 atmospheres in the tank.

[0056] Install a water storage tank valve on the water storage tank and connect it with the booster pump inlet. Install a water inlet check valve at the outlet of the booster pump, install a water inlet valve on the ozone water generating tank, and connect the two valves to prevent the water in the tank from flowing back from the water inlet. An elliptical rotary nozzle is installed in the ozone water generating tank and connected with the water inlet valve on the tank. The volume of the ozone water generation tank is 80L.

[0057] Install a pressure vacuum gauge on the ozone water generating tank to measure the vacuum degree and gauge pressure in the tank. A vacuum valve is installed on the ozone water generating tank and connected with a vacuum pump for vacuumizing the inside of the tank. An ozone inlet valve is installed at the lower part of th...

Embodiment 3

[0063] In this embodiment, for the ozone gas under 2 atmospheres in the tank, the water inlet pressure is changed to dissolve and prepare high-concentration ozone water.

[0064] Install a water storage tank valve on the water storage tank and connect it with the booster pump inlet. Install a water inlet check valve at the outlet of the booster pump, install a water inlet valve on the ozone water generating tank, and connect the two valves to prevent the water in the tank from flowing back from the water inlet. An elliptical rotary nozzle is installed in the ozone water generating tank and connected with the water inlet valve on the tank. The volume of the ozone water generating tank is 150L.

[0065] Install a pressure vacuum gauge on the ozone water generating tank to measure the vacuum degree and gauge pressure in the tank. A vacuum valve is installed on the ozone water generating tank and connected with a vacuum pump for vacuumizing the inside of the tank. An ozone inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com