Bifunctional adsorbent of N-TiO2 silkworm-excrement porous carbon and preparation method of bifunctional adsorbent

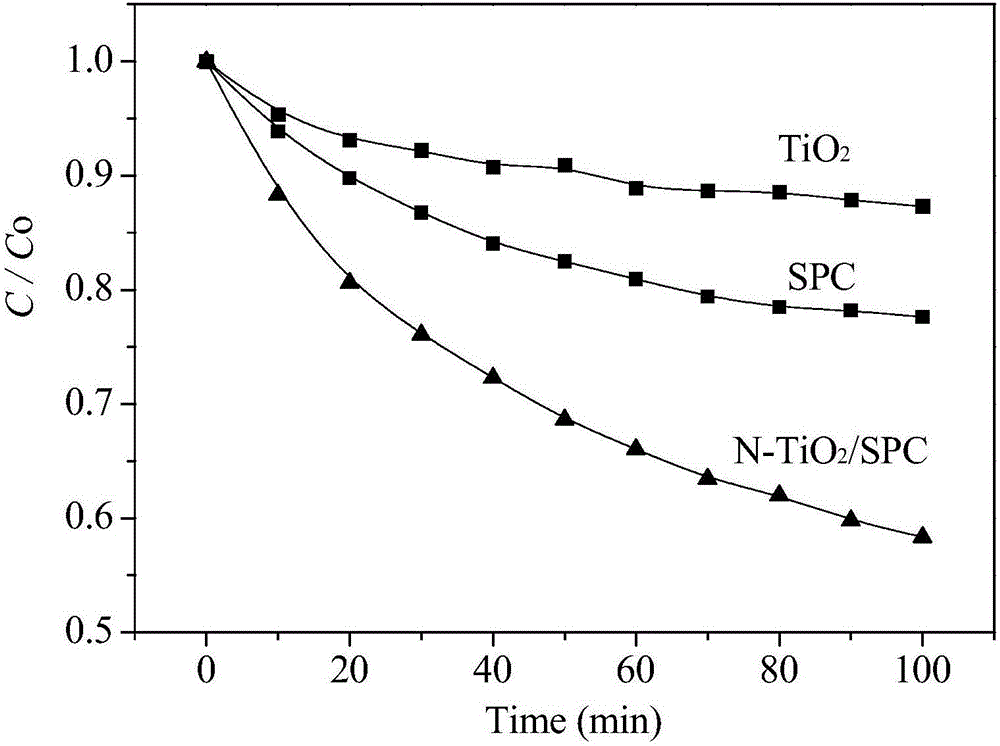

A porous carbon and bifunctional technology, which is applied in the field of N-TiO2 silkworm sand porous carbon bifunctional adsorbent material and its preparation field, can solve the problem of difficult hydrophobicity and high selectivity adsorption of aldehyde VOCs, etc., and achieve high VOCs capture capacity , reducing energy consumption, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

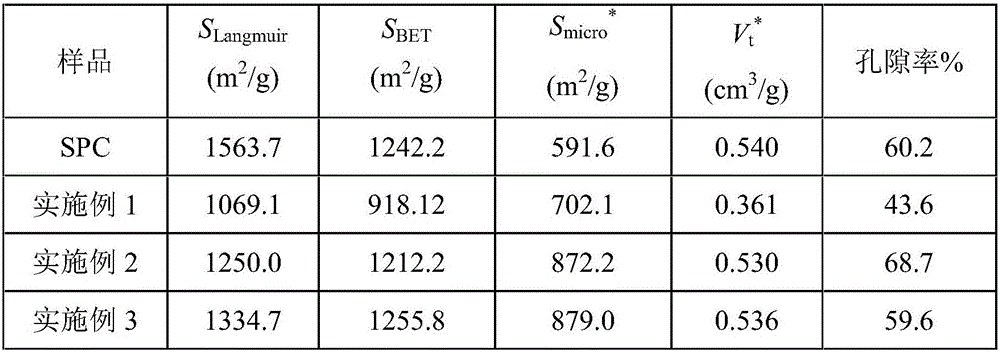

Embodiment 1

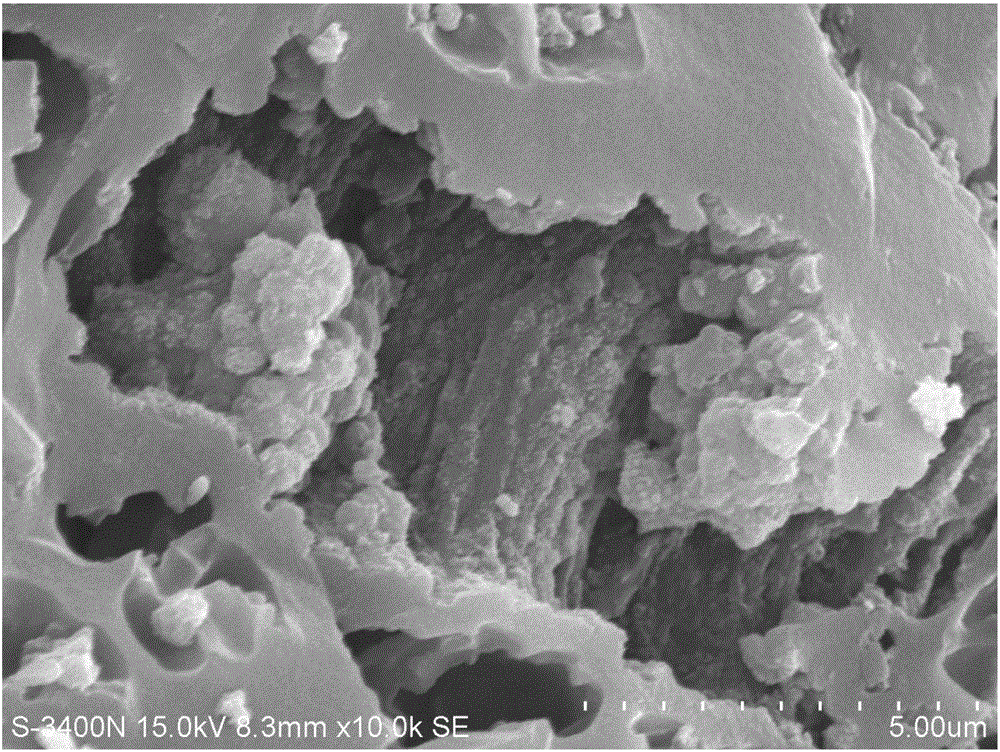

[0029] A kind of N-TiO 2 The preparation method of silkworm excrement porous carbon bifunctional adsorbent comprises the following steps,

[0030] (1) Preparation of silkworm excrement porous carbon

[0031] in N 2 In the atmosphere, 10.0g of original silkworm excrement and 10.0g of ZnCl 2 The powder was raised to 300°C at a heating rate of 2°C / min, kept at 300°C for 3 hours, and then cooled to room temperature to obtain silkworm excrement porous carbon, denoted as SPC.

[0032] (2) A-TiO 2 Preparation of silkworm excrement porous carbon material;

[0033] Add the ethylene glycol solution (5 mL) containing 1.0 g butyl titanate dropwise to the aqueous solution containing 0.3 g silkworm excrement porous carbon (the aqueous solution is 2.5 mL), and stir vigorously until fully hydrolyzed to form amorphous TiO 2 , to prepare A-TiO 2 Silkworm excrement porous carbon material;

[0034] (3)N-TiO 2 Preparation of silkworm excrement porous carbon material;

[0035] The prepared...

Embodiment 2

[0037] A kind of N-TiO 2 The preparation method of silkworm excrement porous carbon bifunctional adsorbent comprises the following steps,

[0038] (1) Preparation of silkworm excrement porous carbon

[0039] in N 2 In the atmosphere, 10.0g of original silkworm excrement and 30.0g of ZnCl 2The powder was raised to 400°C at a heating rate of 5°C / min, kept at 400°C for 5 hours, and then cooled to room temperature to obtain silkworm excrement porous carbon, denoted as SPC.

[0040] (2) A-TiO 2 Preparation of silkworm excrement porous carbon material;

[0041] Add the ethanol solution (30mL) containing 1.0g butyl titanate dropwise to the aqueous solution containing 0.6g silkworm excrement porous carbon (the aqueous solution is 15mL), and stir vigorously until fully hydrolyzed to form amorphous TiO 2 , to prepare A-TiO 2 Silkworm excrement porous carbon material;

[0042] (3)N-TiO 2 Preparation of silkworm excrement porous carbon material;

[0043] The prepared A-TiO 2 Put...

Embodiment 3

[0045] A kind of N-TiO 2 The preparation method of silkworm excrement porous carbon bifunctional adsorbent comprises the following steps,

[0046] (1) Preparation of silkworm excrement porous carbon

[0047] in N 2 In the atmosphere, 10.0g of original silkworm excrement and 60.0g of ZnCl 2 The powder was raised to 600°C at a heating rate of 5°C / min, kept at 600°C for 2 hours, and then cooled to room temperature to obtain silkworm excrement porous carbon, denoted as SPC.

[0048] (2) A-TiO 2 Preparation of silkworm excrement porous carbon material;

[0049] Add the ethanol solution (15mL) containing 1.0g butyl titanate dropwise to the aqueous solution containing 0.9g silkworm excrement porous carbon (the aqueous solution is 30mL), and stir vigorously until fully hydrolyzed to form amorphous TiO 2 , to prepare A-TiO 2 Silkworm excrement porous carbon material;

[0050] (3)N-TiO 2 Preparation of silkworm excrement porous carbon material;

[0051] The prepared A-TiO 2 Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com