Method for modifying activated carbon and application thereof

An activated carbon and modified technology, applied in chemical instruments and methods, other chemical processes, textile industry wastewater treatment, etc., can solve the problems of large concentration, large water quality changes, difficult treatment, etc., and achieve low cost, high adsorption rate, High use-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

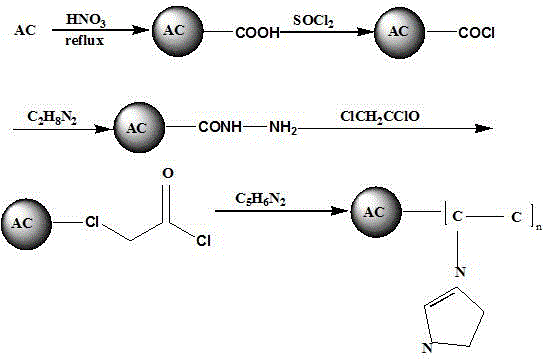

[0019] Such as figure 1 Shown, the method for this modified activated carbon, its concrete steps are as follows:

[0020] (1) First, add 100g of activated carbon to the liquid-solid ratio of 100:20ml / g, add concentrated nitric acid (the concentration of concentrated nitric acid is 60% g / ml) and mix and reflux for 10 hours. After the reaction, wash with water until the pH is equal to 7, and dry to obtain the modification Product I;

[0021] (2) Mix thionyl chloride and DMF uniformly according to the volume ratio of 10:40 to obtain the mixed organic liquid I, and then add the modified product I obtained in step (1) into the mixed organic liquid according to the liquid-solid ratio of 50:19ml / g Liquid I was electromagnetically stirred at 60°C for 10 hours, filtered and washed with DMF after the reaction, and dried to obtain modified product II;

[0022] (3) Mix ethylenediamine and DMF uniformly according to the volume ratio of 10:40 to obtain the mixed organic liquid II, then ad...

Embodiment 2

[0028] Such as figure 1 Shown, the method for this modified activated carbon, its concrete steps are as follows:

[0029] (1) First, add 100g of activated carbon into concentrated nitric acid (the concentration of concentrated nitric acid is 90% g / ml) according to the liquid-solid ratio of 150:25ml / g, mix and reflux for 12 hours. After the reaction, wash with water until the pH is equal to 7, and dry to obtain the modification Product I;

[0030] (2) Mix thionyl chloride and DMF uniformly according to the volume ratio of 12:50 to obtain the mixed organic liquid I, and then add the modified product I obtained in step (1) into the mixed organic liquid according to the liquid-solid ratio of 75:25ml / g Liquid I was electromagnetically stirred at 80°C for 12 hours, filtered and washed with DMF after the reaction, and dried to obtain modified product II;

[0031] (3) Mix ethylenediamine and DMF uniformly according to the volume ratio of 15:45 to obtain the mixed organic liquid II, ...

Embodiment 3

[0037] Such as figure 1 Shown, the method for this modified activated carbon, its concrete steps are as follows:

[0038] (1) First, add 100g of activated carbon into concentrated nitric acid (the concentration of concentrated nitric acid is 80% g / ml) according to the liquid-solid ratio of 125:23ml / g, mix and reflux for 11 hours. After the reaction, wash with water until the pH is equal to 7, and dry to obtain the modification Product I;

[0039] (2) Mix thionyl chloride and DMF uniformly according to the volume ratio of 15:60 to obtain the mixed organic liquid I, and then add the modified product I obtained in step (1) into the mixed organic liquid according to the liquid-solid ratio of 63:22ml / g Liquid I was electromagnetically stirred at 70°C for 11 hours, filtered and washed with DMF after the reaction, and dried to obtain modified product II;

[0040] (3) Mix ethylenediamine and DMF uniformly according to the volume ratio of 20:50 to obtain the mixed organic liquid II, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com