Adhesive tape foreign matter synchronous removal device

A technology for removing devices and foreign objects, applied in the field of mechanical devices, can solve problems such as reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention provides a device for synchronously removing foreign matter from rubber strips, the specific structure of which is as follows:

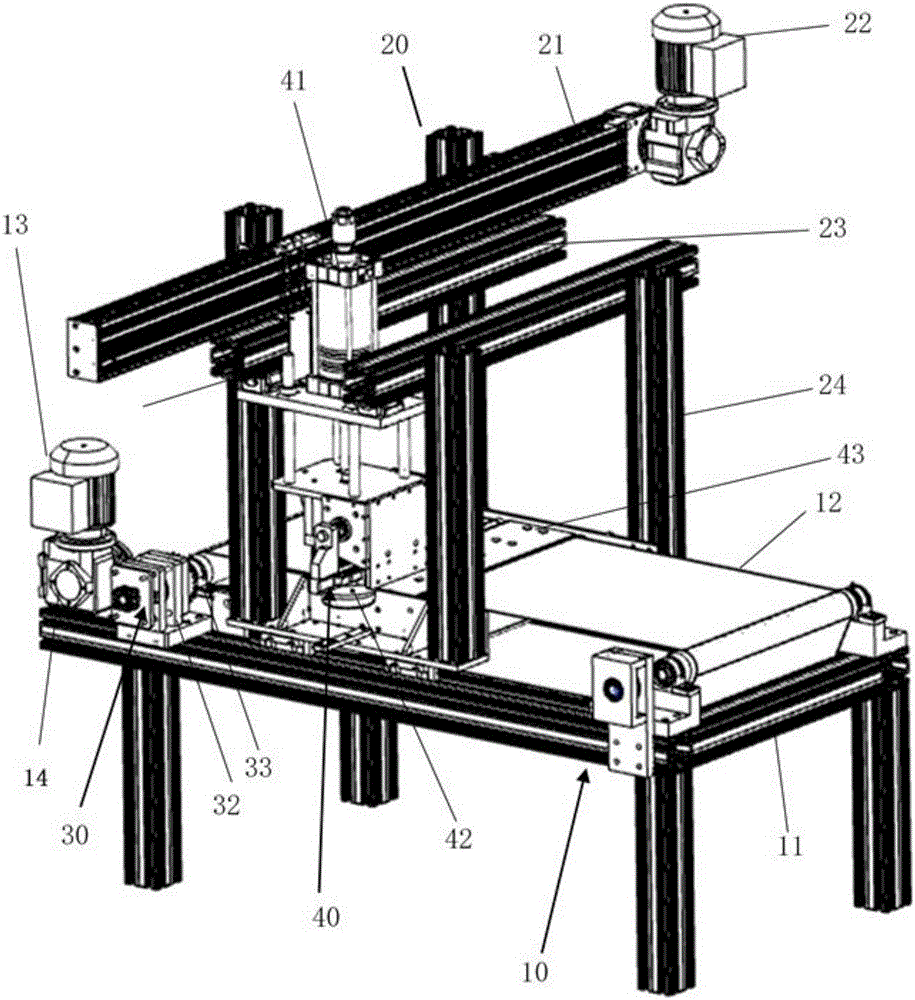

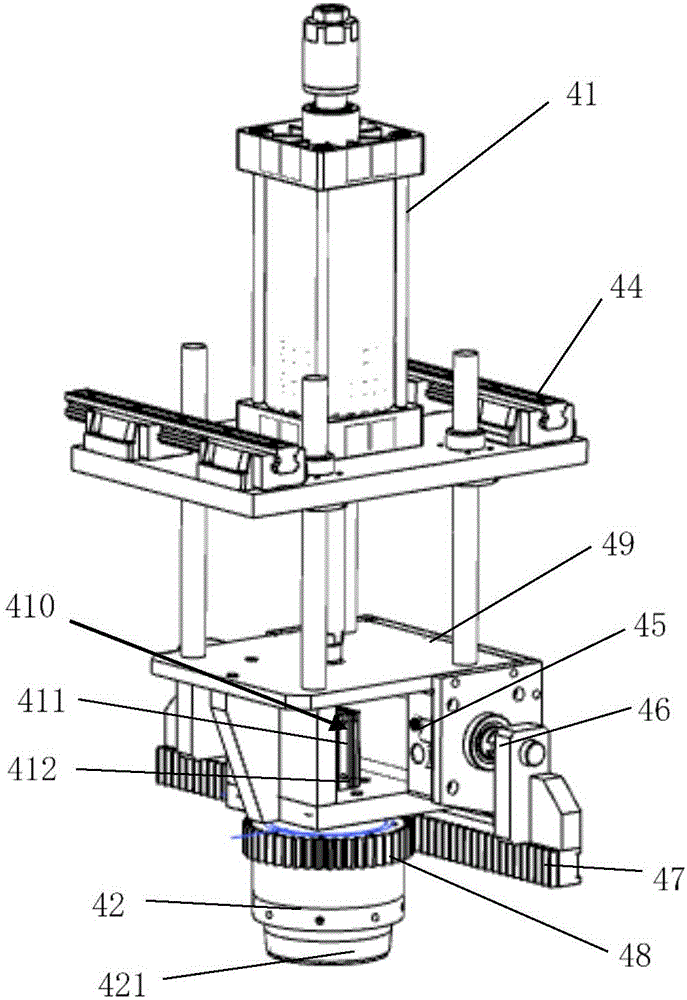

[0025] figure 1 Shown is the overall structural diagram of the synchronous rejecting device of the present invention, including a material conveying system 10 , a foreign matter positioning mechanism 20 , a synchronous mechanism 30 , and a rejecting mechanism 40 .

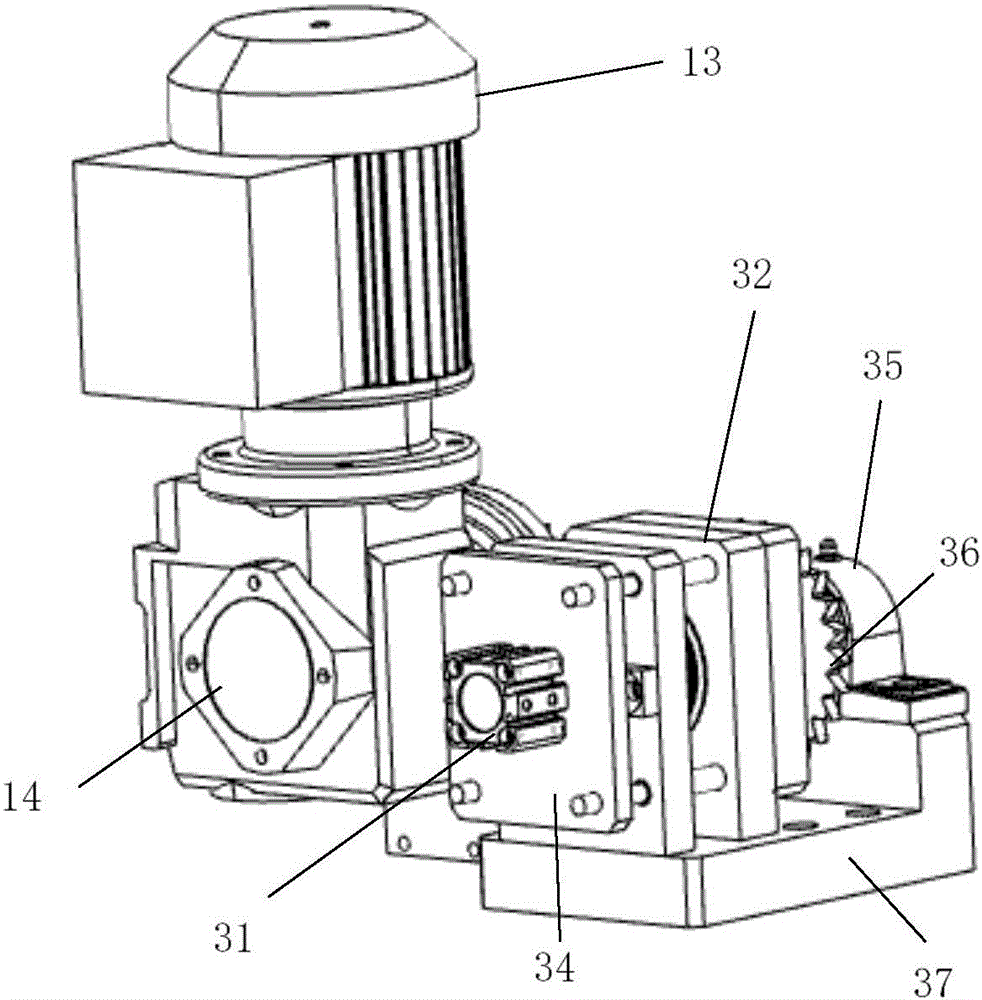

[0026] Wherein the material conveying system 10 comprises an equipment base 11, a conveyor belt 12, a first drive motor 13 and a reducer 14, and the first drive motor 13 drives the conveyor belt 12 to rotate through the reducer 14; the foreign matter positioning mechanism 20 comprises a positioning guide rail 21, a second drive motor 22, grating ruler 23 and base 24, grating ruler 23 is installed parallel to positioning guide rail 21, is used to detect the actual position of rejecting mechanism 40, guide rail 21 is installed on the base 24, and base 24 lower ends are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com