Die and method for avoiding shrinkage and slag inclusion of metal mold aerospace casting

A technology for metal molds and castings, used in metal processing equipment, casting molds, cores, etc., can solve the problems of slag inclusion, affecting the cost of castings and shipping requirements, shrinkage porosity, etc., and achieve the effect of reducing shrinkage porosity and slag inclusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture Embodiment 1

[0026] To solve the method of shrinkage and slag inclusion of metal-type aviation castings, cast metal-type aviation castings according to the following steps:

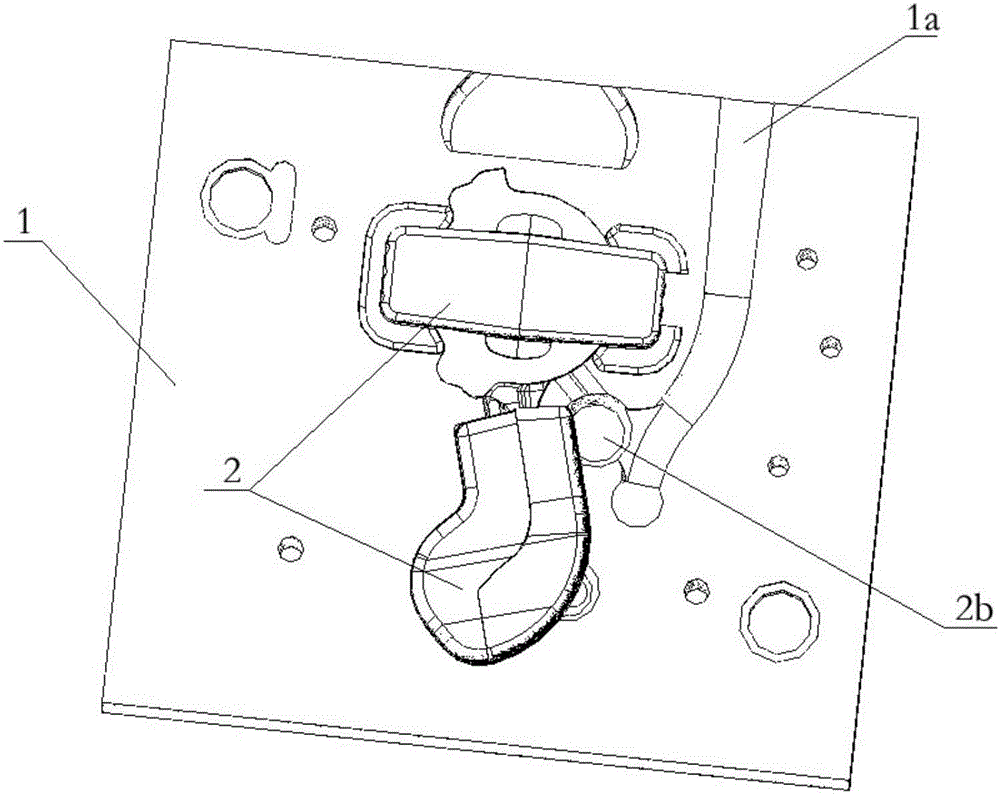

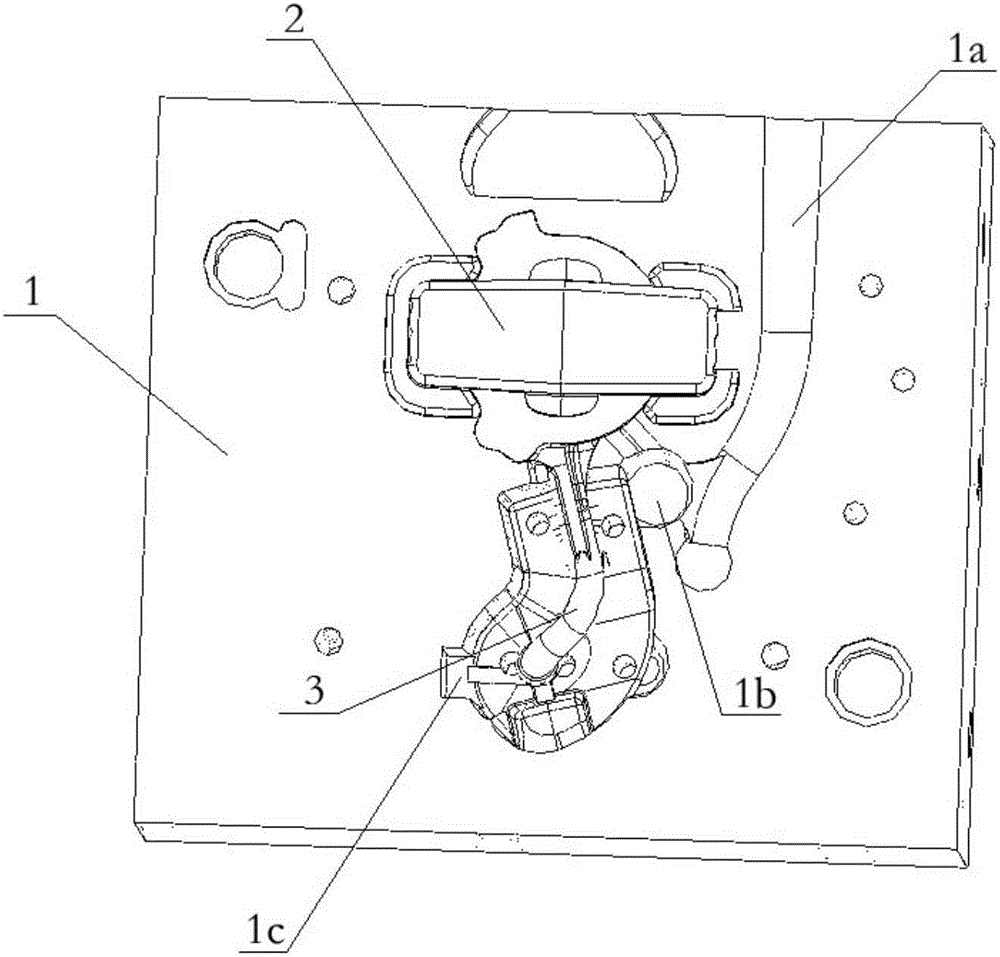

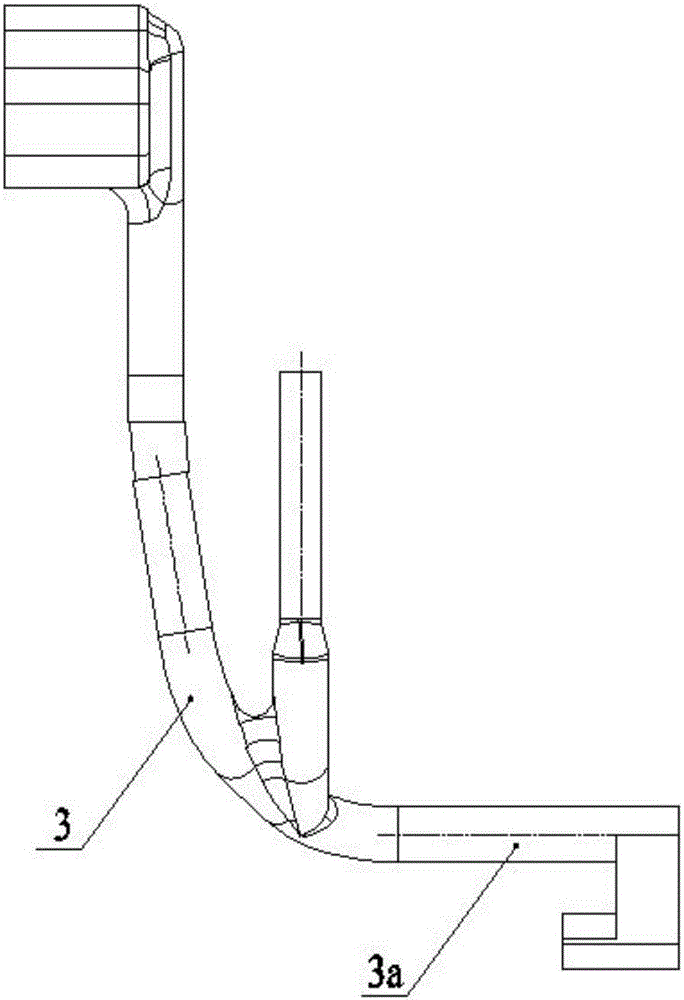

[0027] (1) Use high-strength coated sand to make the inner sand core 3 of the pipeline, and use low-outgassing coated sand to make the outer shell sand core 2, then dip the sand core with paint, and brush the surface of the sand core 3 in the pipeline after drying Apply a layer of chilled paint and drill vent holes;

[0028] (2) Place the mold horizontally first, heat it to 150°C, prepare to paint the mold after it reaches temperature, evenly spread refractory fiber paste on the sprue 1a, sprue riser and dark riser 1b of the mold body 1, and then brush FOSECO 34# thermal insulation coating;

[0029] (3) After the above processes are ready, start casting. After opening the mold, gently put the inner sand core 3 and the outer shell sand core 2 prepared in step (1) into the corresponding positions in the mold body 1, an...

manufacture Embodiment 2

[0031] To solve the method of shrinkage and slag inclusion of metal-type aviation castings, cast metal-type aviation castings according to the following steps:

[0032] (1) Use high-strength coated sand to make the inner sand core 3 of the pipeline, and use low-outgassing coated sand to make the outer shell sand core 2, then dip the sand core with paint, and brush the surface of the sand core 3 in the pipeline after drying Apply a layer of chilled paint and drill vent holes;

[0033] (2) Place the mold horizontally first, heat it to 175°C, prepare to paint the mold after it reaches temperature, evenly spread refractory fiber paste on the runner 1a, sprue riser and dark riser 1b of the mold body 1, and then brush FOSECO 34# thermal insulation coating;

[0034] (3) After the above processes are ready, start casting. After opening the mold, gently put the inner sand core 3 and the outer shell sand core 2 prepared in step (1) into the corresponding positions in the mold body 1, a...

manufacture Embodiment 3

[0036] To solve the method of shrinkage and slag inclusion of metal-type aviation castings, cast metal-type aviation castings according to the following steps:

[0037] (1) Use high-strength coated sand to make the inner sand core 3 of the pipeline, and use low-outgassing coated sand to make the outer shell sand core 2, then dip the sand core with paint, and brush the surface of the sand core 3 in the pipeline after drying Apply a layer of chilled paint and drill vent holes;

[0038] (2) Place the mold horizontally first, heat it to 200°C, prepare to paint the mold after it reaches temperature, evenly spread refractory fiber paste on the runner 1a, sprue riser and dark riser 1b of the mold body 1, and then brush FOSECO 34# thermal insulation coating;

[0039] (3) After the above processes are ready, start casting. After opening the mold, gently put the inner sand core 3 and the outer shell sand core 2 prepared in step (1) into the corresponding positions in the mold body 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com