Laser cutting machine

A technology of laser cutting machine and laser knife, applied in the field of cutting device and laser cutting machine, can solve the problems of waste, easy overheating of the cutter head, difficult installation and transportation, etc., to achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

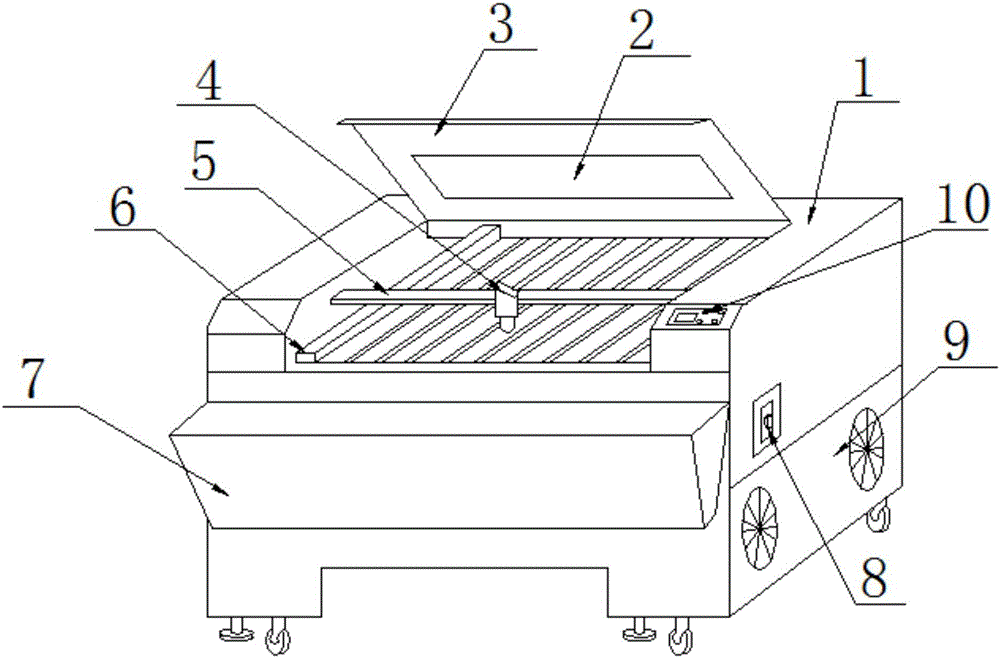

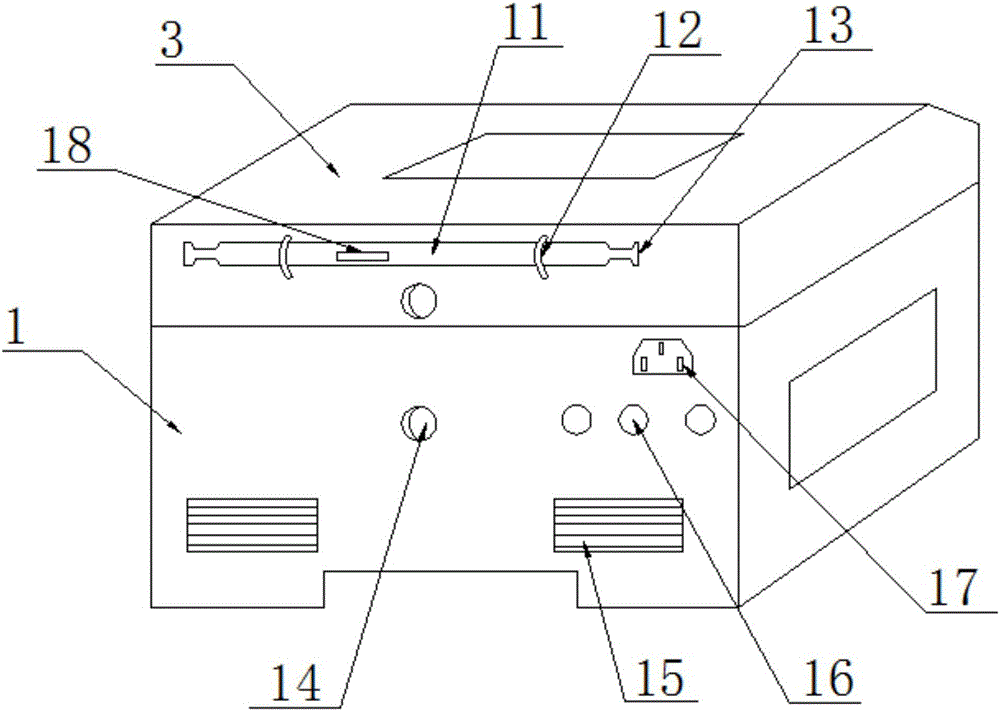

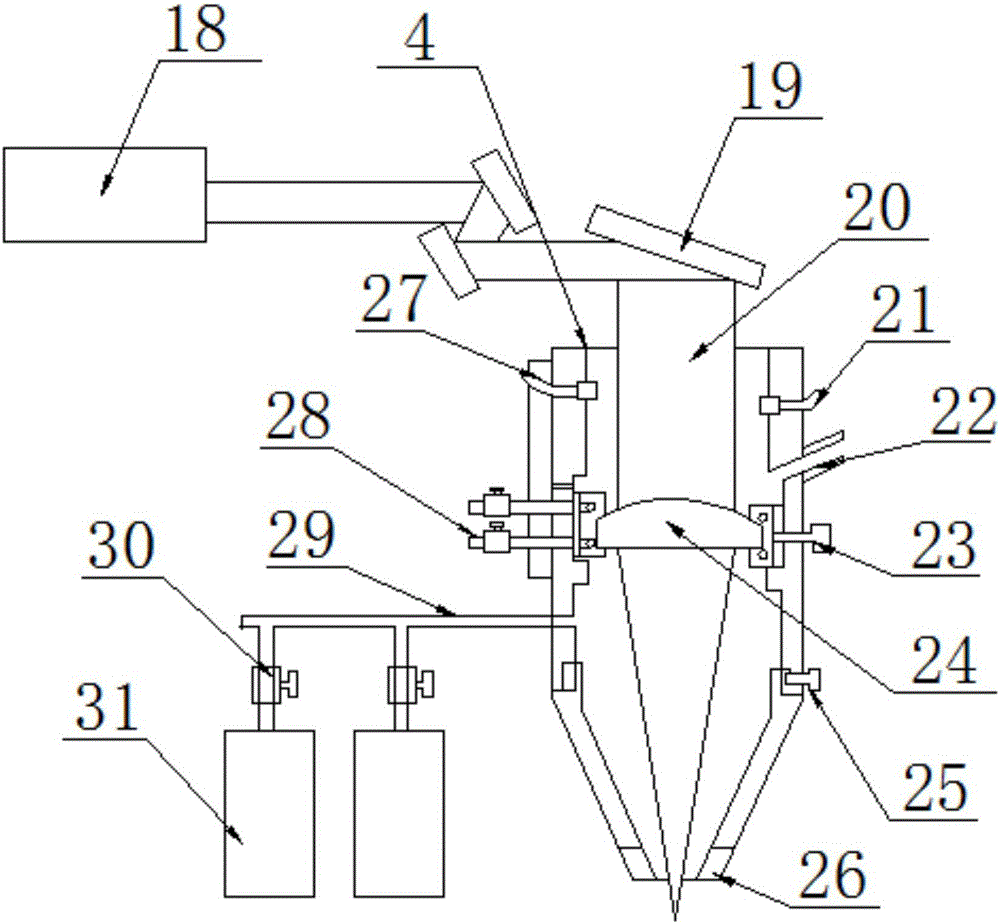

[0020] Such as figure 1 , figure 2 with image 3 As shown, a laser cutting machine provided in this embodiment includes a chassis 1, a transverse guide rail 5, a longitudinal guide rail 6, a drive electric box 15, and a laser cutter head 4. The top center of the chassis 1 is connected to the cover plate 3 through a rotating shaft, and The area of the cover plate 3 is the same as the area of the groove of the chassis 1; the surface of the cover plate 3 is provided with an observation window 2, which can observe the operating conditions inside the device; the surface of the chassis 1 is provided with a control panel 10 near the exit. , to realize automatic operation and easy to use; the side wall of the chassis 1 is provided with a brake switch 8, which can brake with one button and increase the safety performance; the bottom of the brake switch 8 is provided with a cooling fan 9, and the cooling fan 9 is fixed on the bottom of the chassis 1 Inside, the heat accumulated i...

Embodiment 2

[0023] Such as figure 1 , figure 2 with Figure 4As shown, the general structure of the laser cutting machine provided in this embodiment is consistent with that of Embodiment 1, but in order to speed up the work efficiency, wherein the nozzle 26 is a cylindrical nozzle, the laser cutting machine provided in this embodiment, It includes a chassis 1, a horizontal guide rail 5, a longitudinal guide rail 6, a drive electric box 15, and a laser cutter head 4. The top center of the chassis 1 is connected to the cover plate 3 through a rotating shaft, and the area of the cover plate 3 is the same as the area of the groove of the chassis 1. The surface of the cover plate 3 is provided with an observation window 2, which can observe the operating conditions inside the device; the surface of the cabinet 1 is provided with a control panel 10 near the exit, which realizes automatic operation and is easy to use; the side wall of the cabinet 1 The brake switch 8 is set, which can br...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap