A kind of solder for copper/aluminum alloy brazing and preparation method thereof

A technology of aluminum alloy and brazing filler metal, applied in welding equipment, metal processing equipment, welding/cutting medium/material, etc., can solve the problems of poor brazing property, lower melting point, etc., so as to improve the wettability and shorten the wetting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

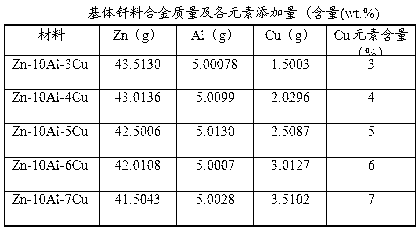

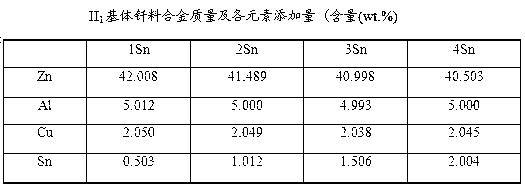

Method used

Image

Examples

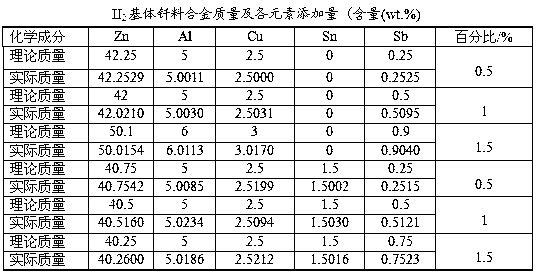

Embodiment 1

[0057] According to the ratio of 81.5% of Zn, 10% of Al, 5% of Cu and 3% of Sn, select elemental Zn, Al, Cu, and Sn to form the base material, and then weigh Sb according to the ratio of 0.5%. Weigh 5g of NaCl and KCl (ratio 1:1); preheat the vacuum heating furnace without vacuuming, set the temperature at 800°C, and make it warm up slowly; In the crucible, NaCl and KCl are covered on it, and 10 g of broken glass is added on top of NaCl and KCl at the same time.

[0058] When the furnace temperature rises to about 450°C, put the crucible containing Zn, Al, NaCl, KCl and cullet into the vacuum furnace for heating to melt it. When the furnace temperature reaches 700°C, open the furnace door and clamp the crucible To the door of the furnace, quickly pour the weighed trace elements Cu, Sb and Sn into the crucible with Zn and Al, stir continuously, and then put it into the heating furnace for re-melting to ensure the uniformity of the developed alloy solder composition. .

[0059...

Embodiment 2

[0061] Select elemental Zn, Al, Cu, and Sn according to the ratio of 80.5-82% Zn, 10% Al, 5% Cu and 3% Sn to form the base material, then weigh Sb according to the ratio of 1.0%, and at the same time Need to weigh 5g of NaCl and KCl (ratio 1:1); preheat the vacuum heating furnace without vacuuming, set the temperature at 800°C, and make it warm up slowly; mix the above-mentioned raw material zinc particles and aluminum flakes according to the composition ratio Place in a crucible, cover with NaCl and KCl, and add 15 g of cullet on top of NaCl and KCl.

[0062] When the furnace temperature rises to about 450°C, put the crucible containing Zn, Al, NaCl, KCl and cullet into the vacuum furnace for heating to melt it. When the furnace temperature reaches 700°C, open the furnace door and clamp the crucible To the door of the furnace, quickly pour the weighed trace elements Cu, Sb and Sn into the crucible with Zn and Al, stir continuously, and then put it into the heating furnace for...

Embodiment 3

[0065] Select elemental Zn, Al, Cu, and Sn according to the ratio of 80.5-82% Zn, 10% Al, 5% Cu and 3% Sn to form the base material, then weigh Sb according to the ratio of 1.5%, and at the same time Need to weigh 5g of NaCl and KCl (ratio 1:1); preheat the vacuum heating furnace without vacuuming, set the temperature at 800°C, and make it warm up slowly; mix the above-mentioned raw material zinc particles and aluminum flakes according to the composition ratio Place in a crucible, cover with NaCl and KCl, and add 12.5 g of cullet on top of NaCl and KCl.

[0066] When the furnace temperature rises to about 450°C, put the crucible containing Zn, Al, NaCl, KCl and cullet into the vacuum furnace for heating to melt it. When the furnace temperature reaches 700°C, open the furnace door and clamp the crucible To the door of the furnace, quickly pour the weighed trace elements Cu, Sb and Sn into the crucible with Zn and Al, stir continuously, and then put it into the heating furnace f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com