A punching and shearing method of a multifunctional punching and shearing machine with high cutting quality and convenient operation

An easy-to-operate punching and shearing machine technology, applied in the direction of feeding devices, manufacturing tools, other manufacturing equipment/tools, etc., to achieve the effects of improving work efficiency and operating safety, high cutting quality, and improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

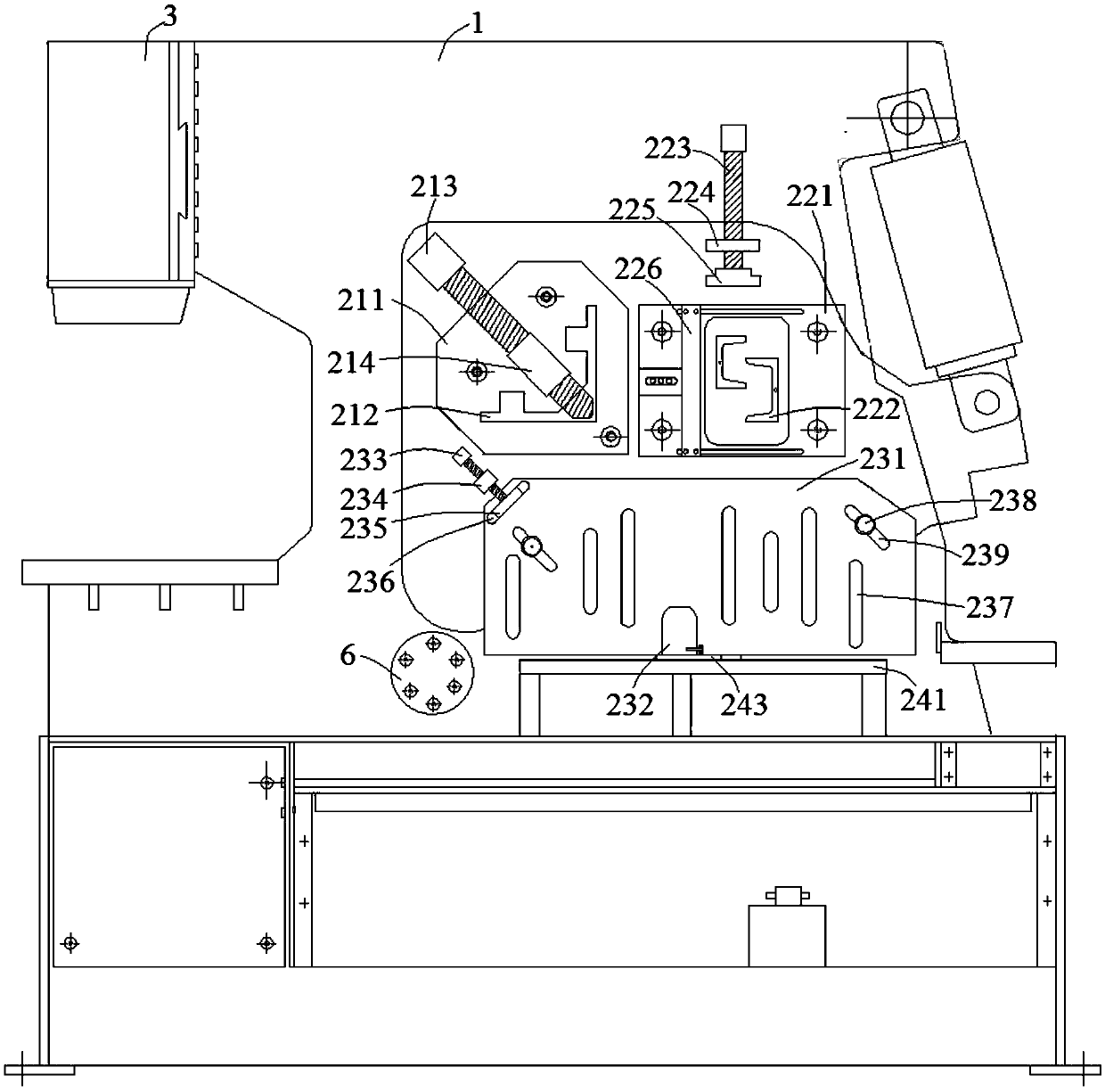

[0060] combine figure 1 , a kind of multifunctional punching and shearing machine with high cutting quality and convenient operation of the present embodiment is provided with a pressing mechanism on the front of the punching and shearing machine body 1, and the pressing mechanism includes 3 pressing stations. components; of which:

[0061] The first pressing assembly includes a first material limiting plate 211, a first pressing screw 213 and a first fixing sleeve 214, the first material limiting plate 211 is fixed on the fuselage 1 by bolts, and the first material limiting plate 211 is provided with a There is a first feeding chute 212, and the first feeding chute 212 is an irregular "L"-shaped structure. The first compression screw 213 is arranged on the first material limiting plate 211 through the first fixing sleeve 214 , and the first compression screw 213 can move toward the top angle direction of the first feeding groove 212 . The first pressing assembly of this emb...

Embodiment 2

[0069] see Image 6 , a multifunctional punching and shearing machine with high cutting quality and convenient operation in this embodiment includes a pressing mechanism for a lower die base. The inventor pointed out that Figure 5 It is a structural schematic diagram of a double-station punching and shearing machine that the inventor applied for before. Considering the structural design of the existing punching and shearing machine, the design of the workbench 423 is relatively short, and the lower mold base 421 is installed on the workbench 423 On the lower mold base 421, two die holes 422 are generally designed. When changing the station, the lower mold base 421 needs to be removed, turned around and then installed on the workbench 423. When punching and cutting profiles of different shapes , It is necessary to replace different punching and shearing dies, so a lot of working time is spent on removing and installing the dies, the labor efficiency is low, and it is very tim...

Embodiment 3

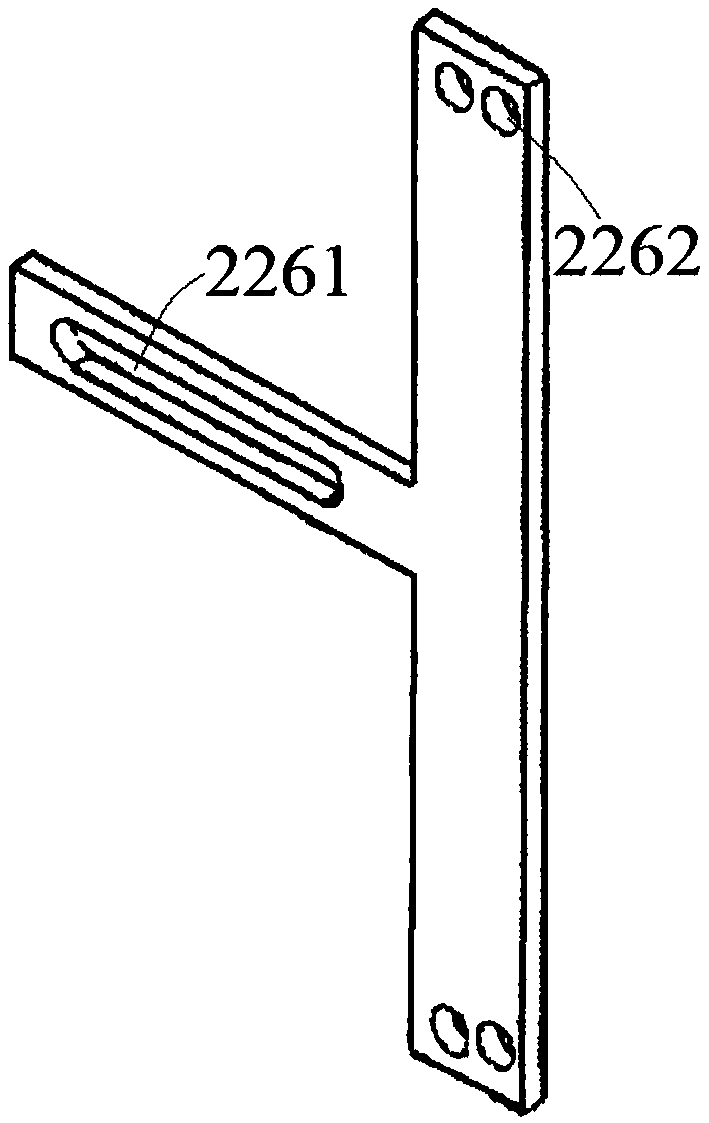

[0074] see Figure 7 with Figure 8 , a multifunctional punching and shearing machine with high cutting quality and convenient operation in this embodiment includes a blade matching mechanism, the core of which blade matching mechanism is a blade matching eccentric shaft 6, and the blade matching eccentric shaft 6 Set the outer fixing plate 61, the first concentric section 63, the second eccentric section 64 and the third concentric section 65 in sequence, the knife plate matches the eccentric shaft 6 and traverses the fuselage 1, and the outer fixing plate 61 is provided with fixing plate screw holes 62 , the outer fixing plate 61 is fixed to the wallboard of the fuselage 1 by inserting bolts into the screw holes 62 of the fixing plate. The knife plate of this embodiment is matched with the eccentric shaft 6. As the name implies, the outer fixing plate 61, the first concentric section 63 and the third concentric section 65 are concentric, and the second eccentric section 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com