Manufacturing process of anti-corrosion high-strength pipeline

A manufacturing process and high-strength technology, applied in the direction of manufacturing tools, reinforced molding, molds, etc., can solve problems such as insufficient compressive strength and use restrictions, and achieve compact structure, long service life, increased compressive strength and corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

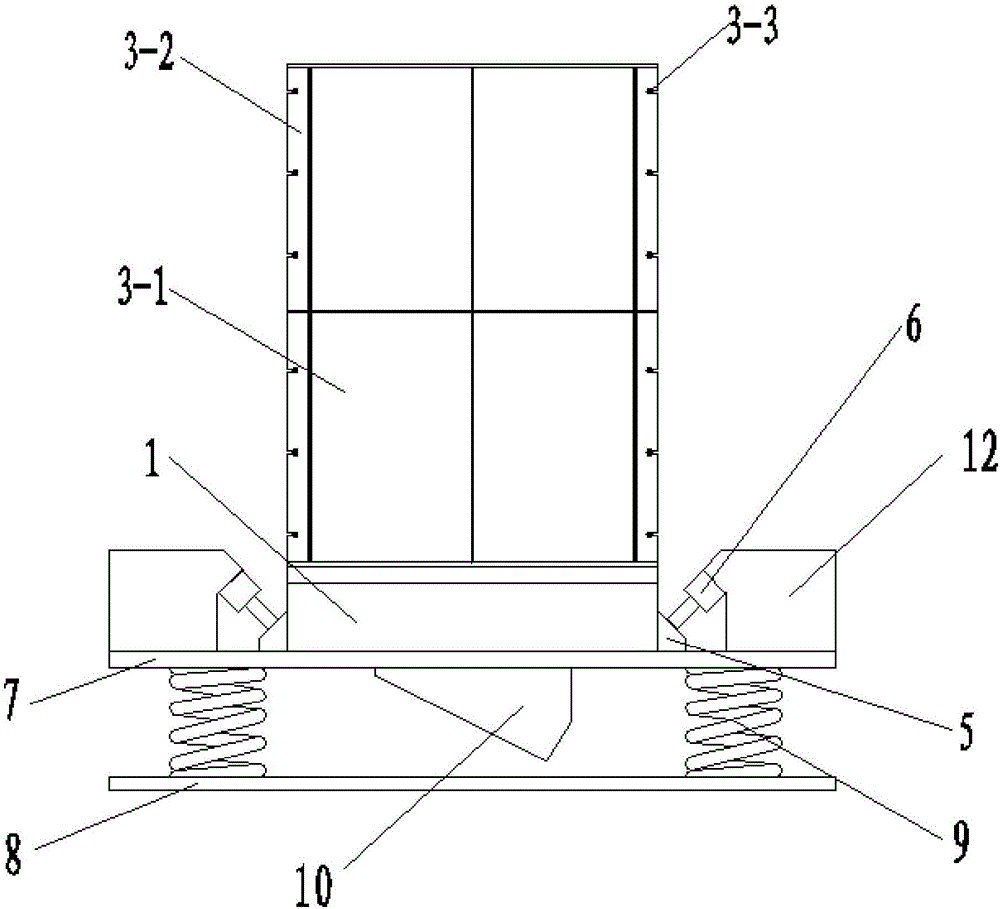

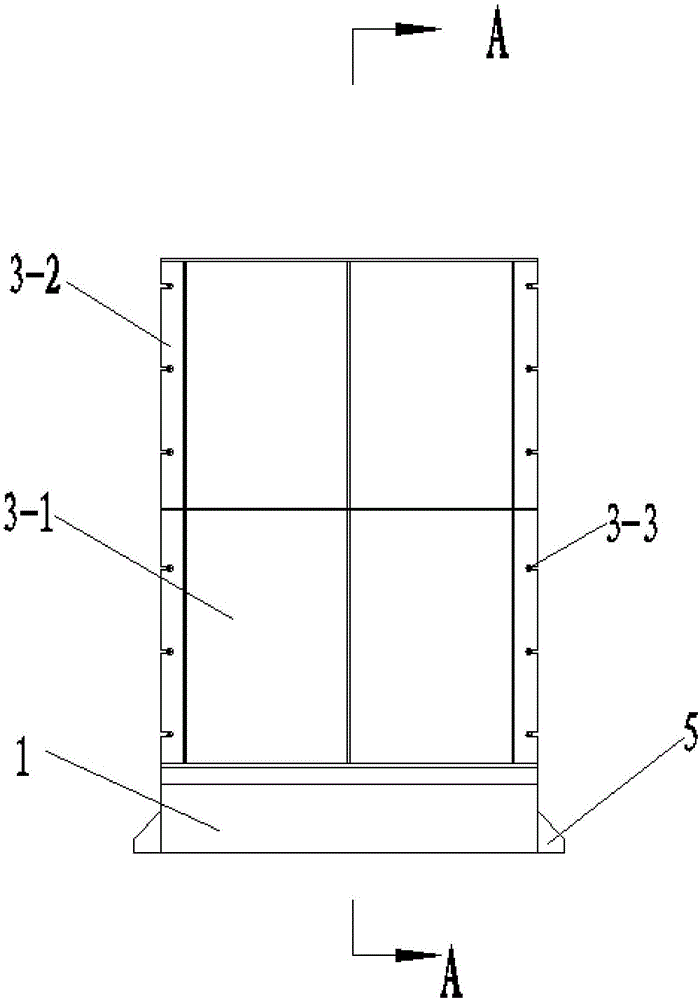

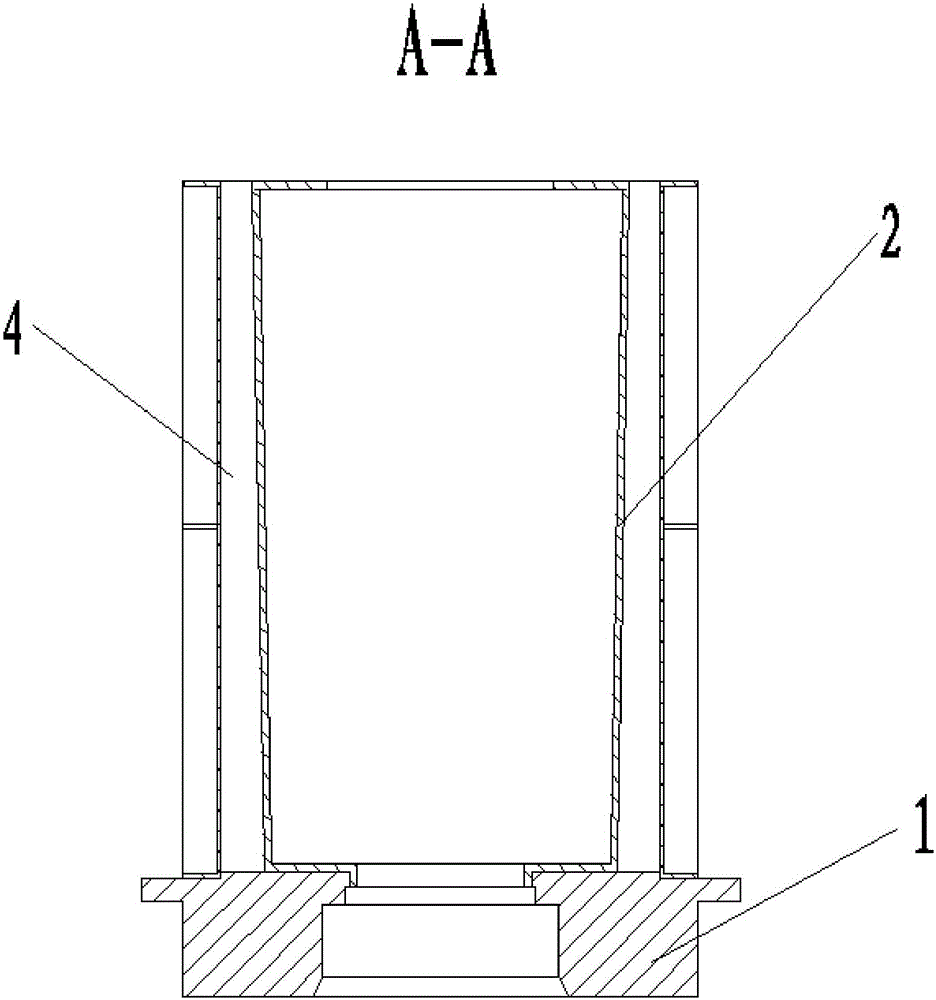

Image

Examples

Embodiment 1

[0039] The process for manufacturing corrosion-resistant high-strength pipelines in this embodiment includes the following steps:

[0040]Step 1. Pour aggregates preheated to 135°C and modified sulfur heated to a molten state into a stirring container, and stir evenly at a constant temperature of 135°C to form thermoplastic concrete; the volume of the modified sulfur is 15% of the above thermoplastic concrete volume;

[0041] The aggregate includes coarse aggregate, fine aggregate and powder filler, the volume of the coarse aggregate is 35% of the volume of the thermoplastic concrete, the volume of the fine aggregate is 35% of the volume of the thermoplastic concrete, The volume of the powder filler is 15% of the volume of the thermoplastic concrete, the volume ratio of the fine aggregate to the coarse aggregate is 1:1; the volume ratio of the modified sulfur to the powder filler is 1:1;

[0042] The coarse aggregate is made of the following raw materials by volume: 75 parts ...

Embodiment 2

[0055] The process for manufacturing corrosion-resistant high-strength pipelines in this embodiment includes the following steps:

[0056] Step 1. Pour aggregates preheated to 125°C and modified sulfur heated to a molten state into a stirring container, and stir evenly at a constant temperature of 125°C to form thermoplastic concrete; the volume of the modified sulfur is 26% of the volume of thermoplastic concrete mentioned above;

[0057] The aggregate includes coarse aggregate, fine aggregate and powder filler, the volume of the coarse aggregate is 42.8% of the volume of the thermoplastic concrete, and the volume of the fine aggregate is 18% of the volume of the thermoplastic concrete, The volume of the powder filler is 13.2% of the volume of the thermoplastic concrete, the volume ratio of the fine aggregate to the coarse aggregate is 0.42:1; the volume ratio of the modified sulfur to the powder filler is 1.97:1;

[0058] The coarse aggregate is made of the following raw ma...

Embodiment 3

[0071] The process for manufacturing corrosion-resistant high-strength pipelines in this embodiment includes the following steps:

[0072] Step 1. Pour aggregates preheated to 148°C and modified sulfur heated to a molten state into a stirring container, and stir evenly at a constant temperature of 146°C to form thermoplastic concrete; the volume of the modified sulfur is 10% of the above thermoplastic concrete volume;

[0073] The aggregate includes coarse aggregate, fine aggregate and powder filler, the volume of the coarse aggregate is 46% of the volume of the thermoplastic concrete, and the volume of the fine aggregate is 36% of the volume of the thermoplastic concrete, The volume of the powder filler is 8% of the volume of the thermoplastic concrete, the volume ratio of the fine aggregate to the coarse aggregate is 0.78:1; the volume ratio of the modified sulfur to the powder filler is 1.25:1;

[0074] The coarse aggregate is made of the following raw materials by volume:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com