Pipe plug of fine grinding mill

A kind of pulverizer, fine technology, applied in the direction of mechanical material recycling, recycling technology, plastic recycling, etc., can solve the problems of low recycling rate, unreasonable structure, inadequate processing, etc., and achieve good recycling, reasonable structure, and design correct effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

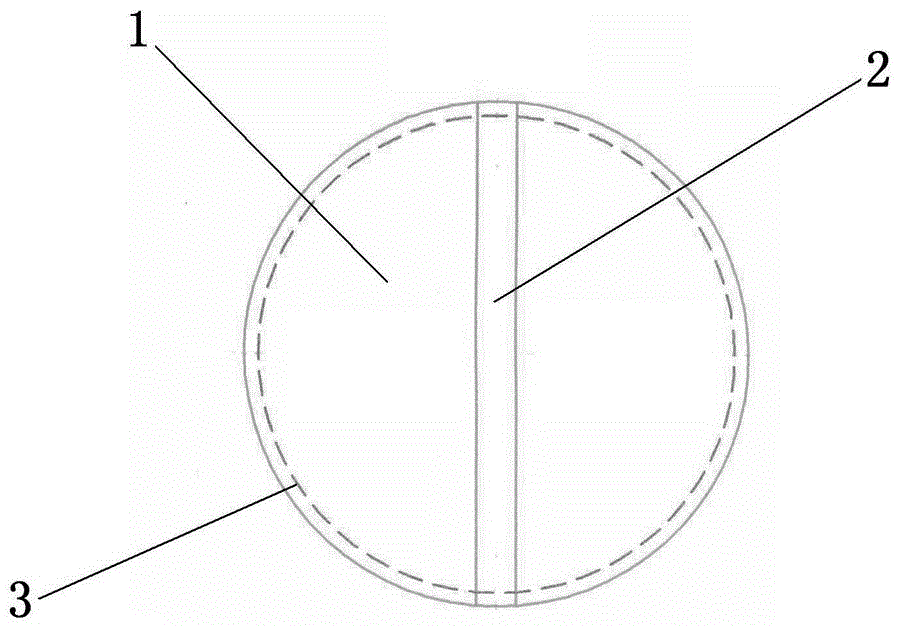

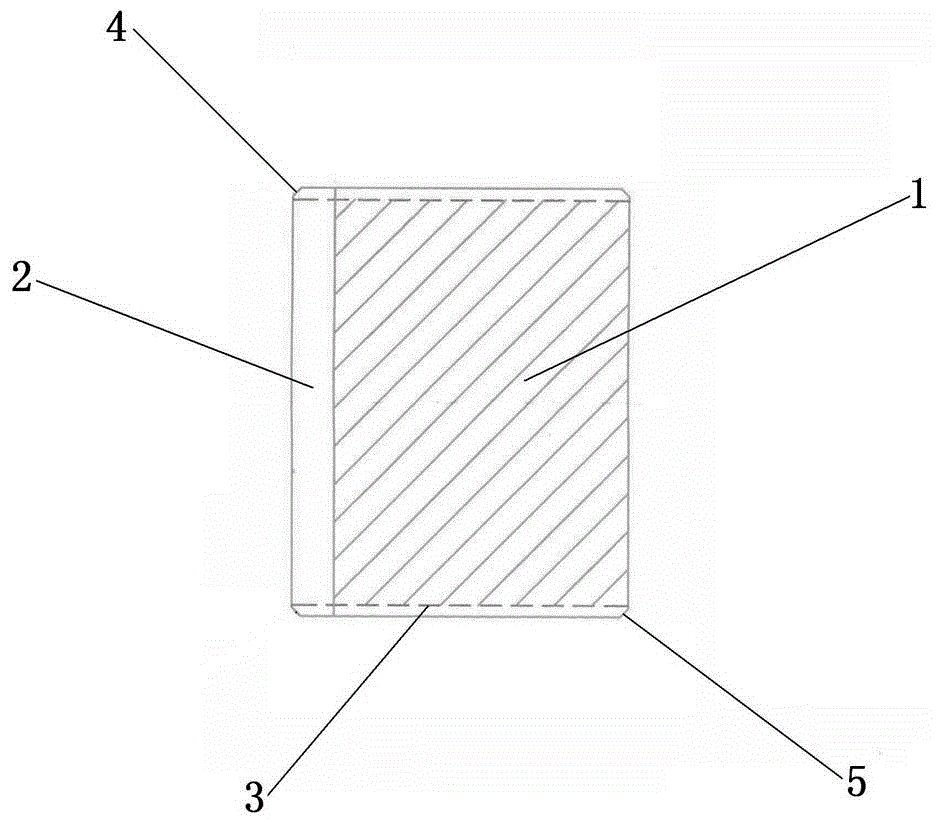

[0009] A pipe plug for a fine grinder, including metal blocks and threads, characterized in that the metal block 1 is in the shape of a cylinder, and the cylindrical metal block 1 is placed in the front and rear directions, with a circular front and a circular rear The diameter of the outer peripheral surface of the metal block 1 is 70mm, the front and rear lengths of the metal block 1 are 40mm, and the outer peripheral surface of the metal block 1 is threaded 3, from the front of the metal block 1 to the The back of the metal block 1; in the middle of the circular front of the metal block 1, a groove 2 is opened longitudinally, and the longitudinal centerline of the groove 2 and the longitudinal centerline of the metal block 1 are located on the same vertical plane; the groove The upper end and the lower end of the groove 2 are arc-shaped, respectively corresponding to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com