Portable rapid air cooling belt connection machine

A portable and splicing machine technology, which is applied to belts, other household appliances, household appliances, etc., can solve the problems of complicated belt production methods, rubber belts that cannot guarantee the best performance, and inconvenience, and achieve smooth and beautiful connection traces and structures. Compact and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

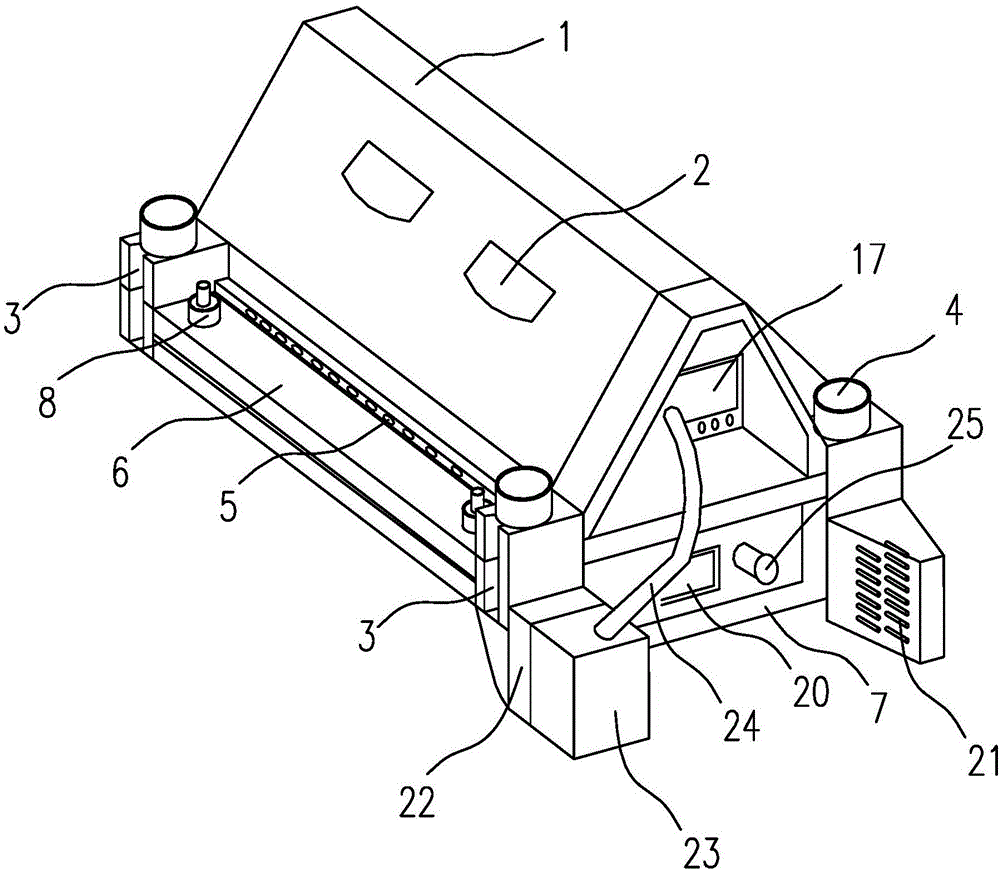

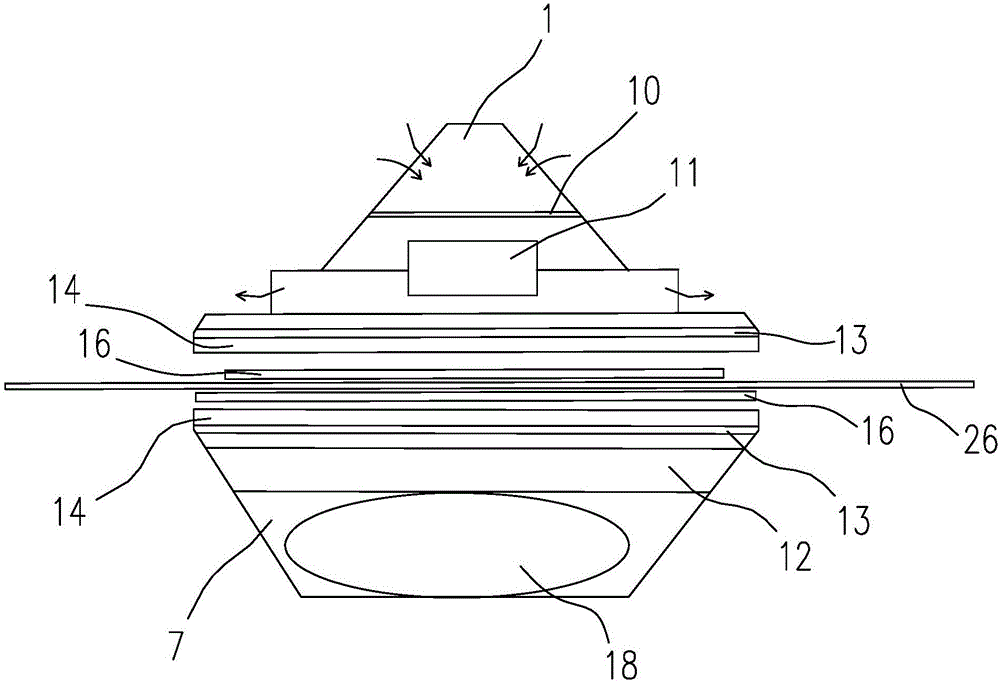

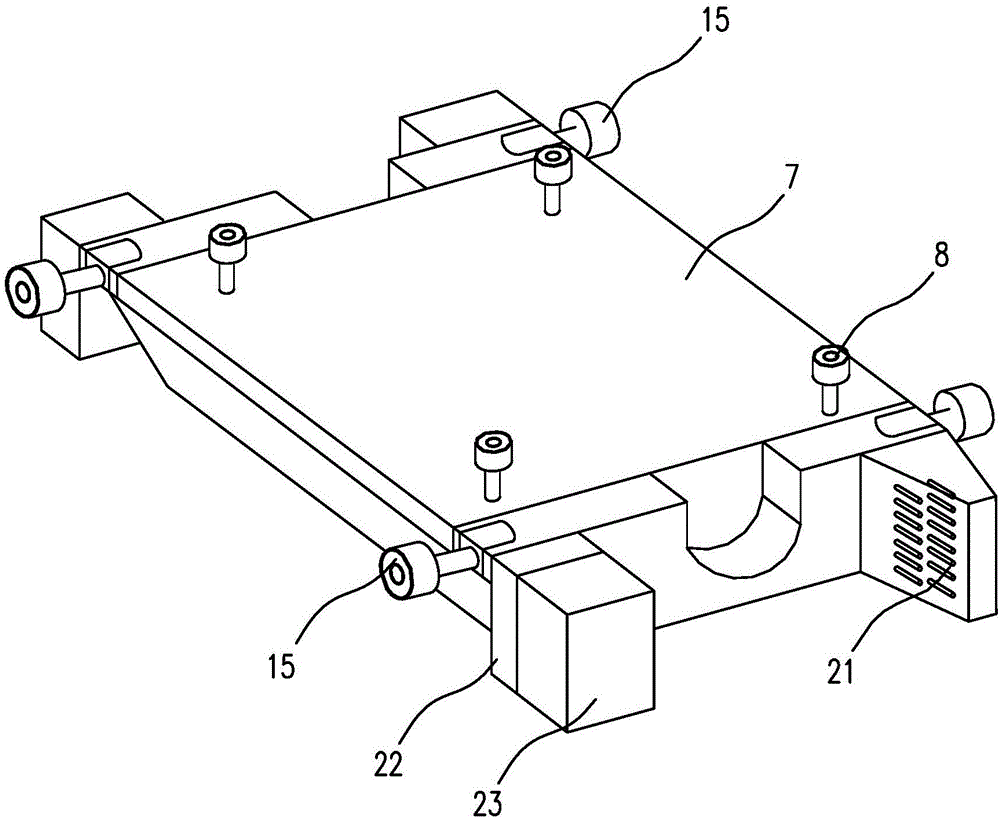

[0022] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

[0023] to combine figure 1 and figure 2 As shown, a portable fast air-cooled belt feeder has an upper beam 1 and a lower beam 7, the bottom of the upper beam 1 is provided with a heating plate 13 and a metal plate 14 from top to bottom, and the top of the lower beam 7 is arranged from the top to the bottom. A metal plate 14, a heating plate 13 and a heat insulation plate 12 are provided in sequence downwards, and the belt 26 is connected by heating and pressure between the metal plates of the upper beam 1 and the lower beam 7,

[0024] Inside the lower beam, an air bag 18 for pressurization is also provided below the heat shield.

[0025] Inside the upper beam, a fan 11 for cooling is also provided above the heat shield.

[0026] The upper side of the upper beam 1 is provided with an air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com