Parallel series dynamical system of engineering machinery

A power system and construction machinery technology, applied in the field of construction machinery hybrid power system, can solve the problems of low energy density, unsuitable continuous drive, low battery power density, etc., and achieve the effect of increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

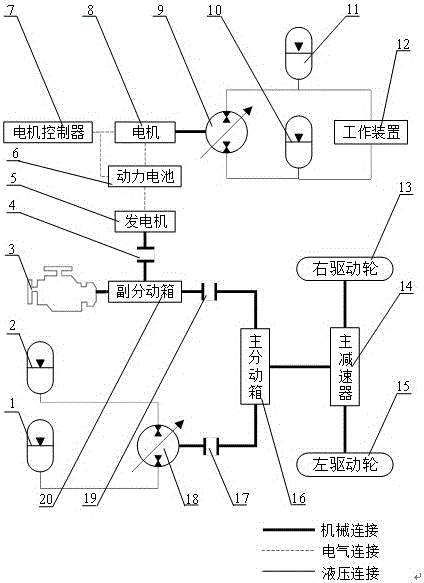

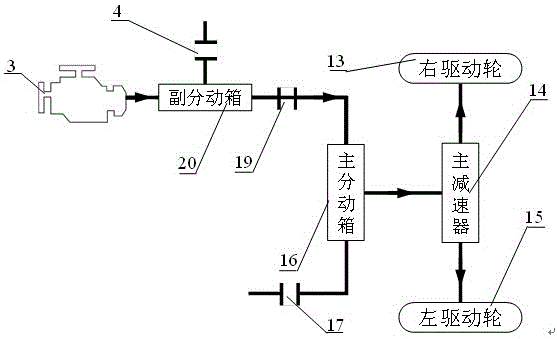

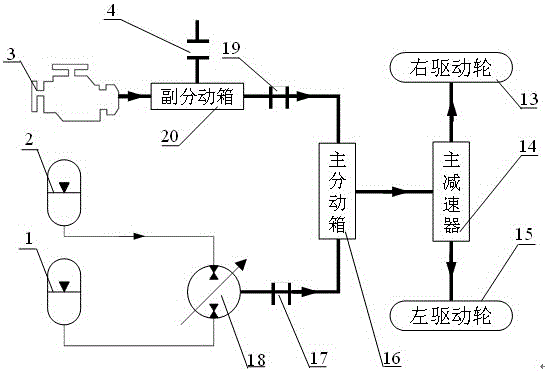

[0030] Example 1: If figure 1 As shown, the hybrid power system of construction machinery includes the power system of the traveling mechanism and the power system of the working device. Reducer 14, left drive wheel 15, main transfer case 16, hydraulic travel drive clutch 17, travel drive pump / motor 18, engine clutch 19 and auxiliary transfer case 20; working device power system consists of generator clutch 4, power generation Machine 5, power battery 6, motor controller 7, motor 8, working device pump / motor 9, working device low-voltage accumulator 10, working device high-voltage accumulator 11 and working device 12. On the one hand, the engine 3 is mechanically connected to the generator 5 through the auxiliary transfer case 20 and the generator clutch 4 . The generator 5, the power battery 6, the motor 8 and the motor controller 7 are electrically connected, and the motor controller 7 can control the switch of the power battery 6 and the running state of the motor 8 (inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com