Direct current magnetic leakage detecting system and method based on triggered acquisition mode

A collection mode and magnetic flux leakage detection technology, which is applied in the direction of material magnetic variables, railway vehicle shape measuring instruments, railway car body parts, etc., can solve the unfavorable processing of data packets, data loss, and the single magnetic flux leakage detection method cannot cover all speed ranges and other problems to achieve the effect of helping analysis and identification, improving utilization and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

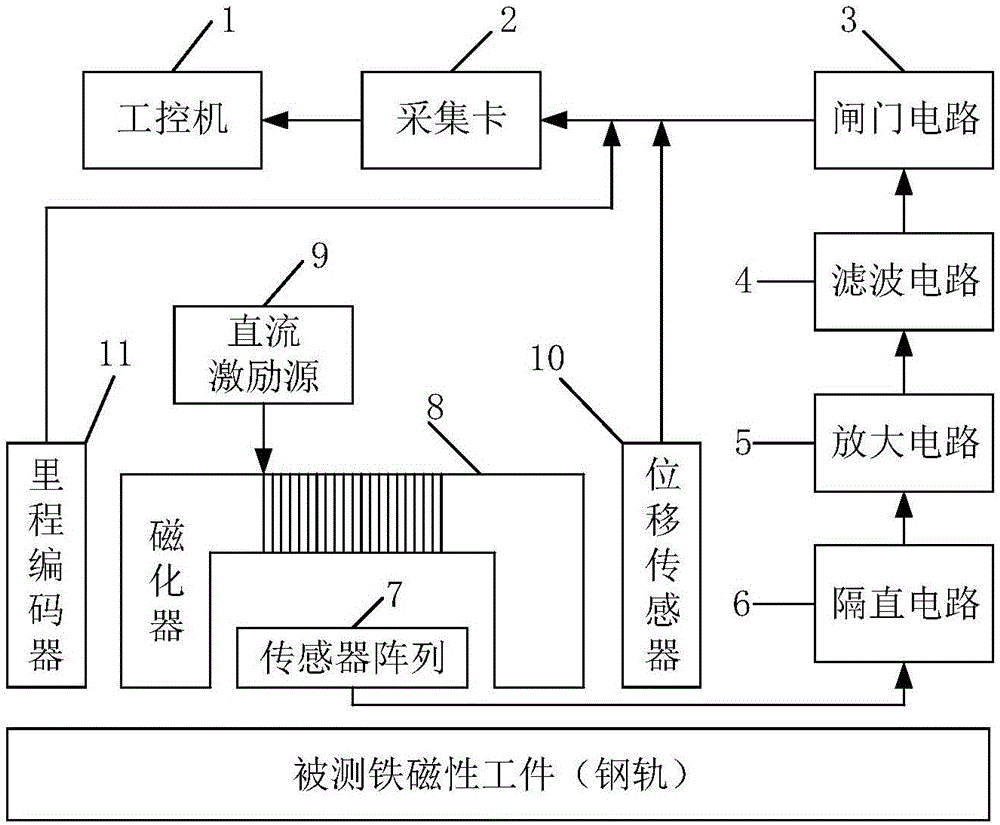

[0036] Such as figure 1 Shown is a system structure block diagram of an embodiment of the present invention. The system of the embodiment of the present invention includes an industrial computer 1 , an acquisition card 2 , a filter circuit 4 , an amplifier circuit 5 , a sensor array 7 , a magnetizer 8 , and a DC excitation source 9 .

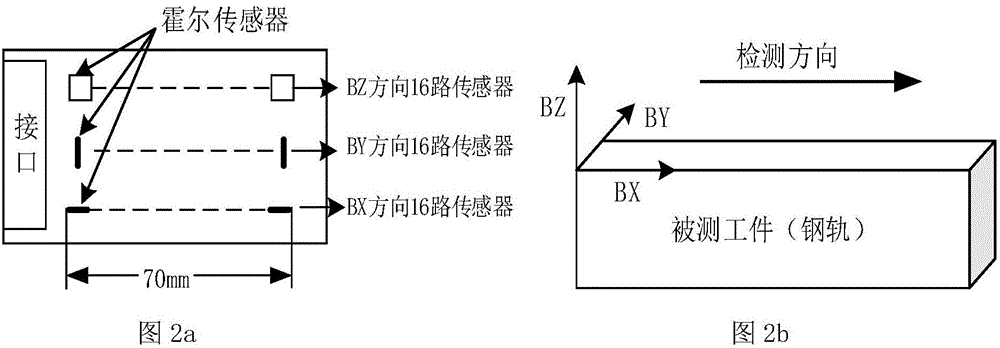

[0037] figure 2 is a schematic diagram of a sensor array according to an embodiment of the present invention. Such as figure 2 As shown, each rail is equipped with 48 Hall sensors, which are divided into 16 Hall sensors in the BX direction (radial direction of the rail, that is, the inspection direction), BY direction (horizontal direction of the rail), and BZ direction (perpendicular to the surface of the rail). , the length is 70mm, which can realize the coverage detection of the entire horizontal direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com