Atmospheric pressure hydrogen reaction device and hydrogen fuel cell power supply system

A reaction device, normal pressure technology, applied in the direction of circuit devices, battery circuit devices, hydrogen, etc., can solve the problem that the controllability and safety of hydrogen production have not been verified, limit the application of in-situ hydrogen production by hydrolysis reaction, and cannot be used in portable Fuel cells and other issues, to achieve the effect of full conversion, improve the uniformity of contact, and reduce the amount of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

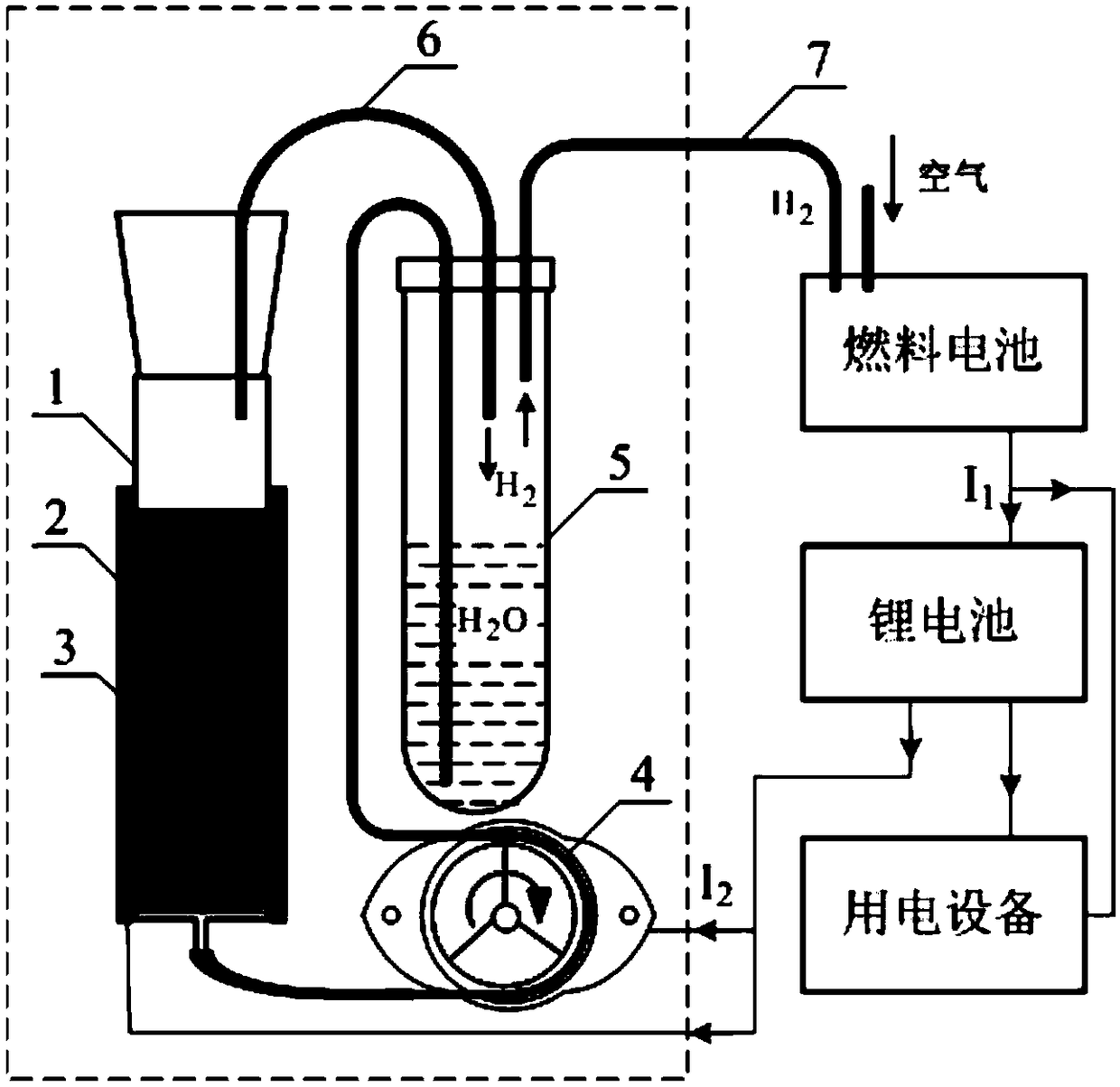

[0054] The reactor 1 is a cylinder with an inner diameter of 3 cm and a height of 20 cm, made of glass, the reactor 1 is placed vertically, and the reaction water is input from the bottom of the reactor 1. The outside of the reactor 1 is heated by a 5W heating jacket 2, and the temperature is controlled by a thyristor relay. The water is transported by the peristaltic pump 4 with a power of 2W, and the water inflow rate can be adjusted according to the rotation speed of the peristaltic pump 4, and the adjustment range is 0.1-3.0mL / min. Both the heating jacket 2 and the peristaltic pump 4 are powered by two lithium batteries, and the battery output voltage is 8V, which are respectively supplied to the heating jacket 2 and the peristaltic pump 4 through a voltage stabilizing device. Water storage tank 5 is 2cm in inner diameter, the cylinder plastic container of high 20cm.

[0055] The rated power of the hydrogen fuel cell is 30W, the open circuit voltage is 12V, the maximum ou...

Embodiment 2

[0061] The reactor 1 is a cylinder with an inner diameter of 3 cm and a height of 20 cm. The reactor 1 is placed vertically, and the reaction water is input from the bottom of the reactor 1 . The outside of the reactor 1 is heated by a 5W heating jacket 2, and the temperature is controlled by a thyristor relay. The water is transported by the peristaltic pump 4 with a power of 2W, and the water inflow rate can be adjusted according to the rotation speed of the peristaltic pump 4, and the adjustment range is 0.1-3.0mL / min. Both the heating jacket 2 and the peristaltic pump 4 are powered by two lithium batteries, and the battery output voltage is 8V, which are respectively supplied to the heating jacket 2 and the peristaltic pump 4 through a voltage stabilizing device. Water storage tank 5 is 2cm in inner diameter, the cylinder plastic container of high 20cm.

[0062] The rated power of the hydrogen fuel cell is 30W, the open circuit voltage is 12V, the maximum output power vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com