Vacuum dechlorinating and purifying method and special vacuum dechlorinating and purifying device for dilute sulfuric acid which is ionic membrane caustic soda byproduct

The technology of ion membrane caustic soda and purification method is applied in the field of vacuum dechlorination purification method of dilute sulfuric acid by-product of ion membrane caustic soda and its special device field, which can solve problems such as difficulty in recycling, reduce corrosion, improve environmental protection benefits, reduce Effect of Chlorine Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

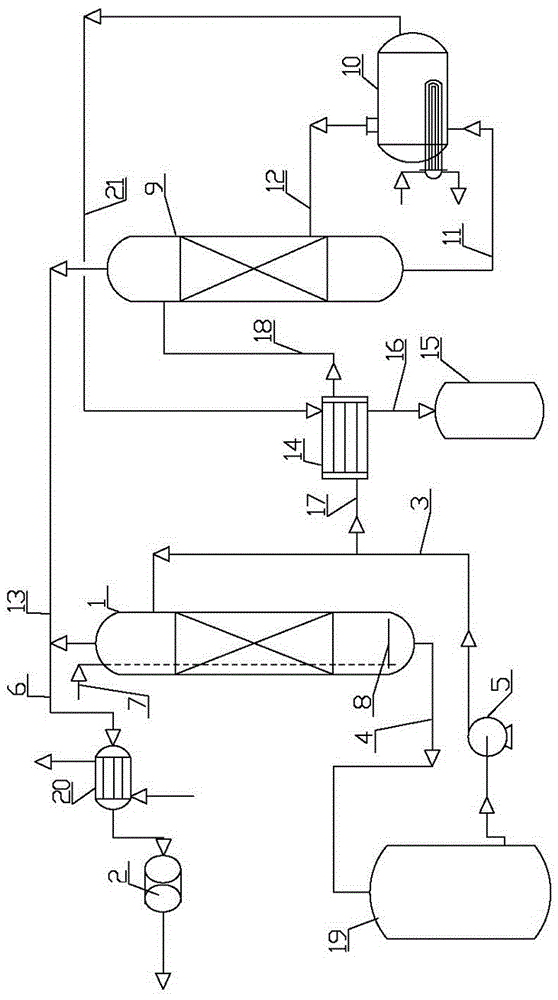

[0020] Embodiment 1: the vacuum dechlorination purification method of this ionic membrane caustic soda by-product dilute sulfuric acid is carried out as follows: the aqueous solution of chlorine-containing dilute sulfuric acid is sent into the dechlorination tower from the top of the dechlorination tower, and then the dechlorination tower The chlorine-containing dilute sulfuric acid aqueous solution in the dechlorination tower is refluxed from the bottom of the dechlorination tower to the top of the dechlorination tower, so that the chlorine-containing dilute sulfuric acid aqueous solution is sent into the dechlorination tower from the top of the dechlorination tower again, that is, the chlorine-containing dilute sulfuric acid aqueous solution The reflux cycle between the bottom of the dechlorination tower and the top of the dechlorination tower, during the reflux cycle of the chlorine-containing dilute sulfuric acid aqueous solution, vacuumize the liquid phase in the dechlorina...

Embodiment 2

[0022]Embodiment 2: As the optimization of the above-mentioned embodiment, the liquid phase after the dechlorination of the dechlorination tower is transported to the top of the analysis tower, and the inside of the analysis tower is vacuumized, and the pressure at the top of the analysis tower is -80KPa to -65KPa , the liquid phase enters the desorption tower from the top of the desorption tower, and then the liquid phase in the desorption tower is transported to the dechlorination evaporator for heating. After the liquid phase is heated, a steam mixture is obtained, and the steam mixture is sent from the lower part of the desorption tower In the desorption tower, the vapor mixture flows upwards in the desorption tower, and during the upward flow, the vapor mixture contacts the liquid phase flowing down from the top of the desorption tower in reverse and performs mass transfer and heat exchange, so that the free dissolved in the liquid phase Chlorine and chlorine gas are separ...

Embodiment 3

[0023] Embodiment 3: as the optimization of embodiment 2, the temperature in the desorption tower is 70 ℃ to 90 ℃; Or / and, when vacuumizing the desorption tower, the chlorine in the desorption tower is extracted out of the desorption tower; Or / and , the dechlorinated sulfuric acid aqueous solution extracted from the dechlorination evaporator is heat-exchanged with the liquid phase before entering the desorption tower, to increase the temperature of the liquid phase entering the dechlorination tower, the temperature of the dechlorinated sulfuric acid aqueous solution exported from the dechlorination evaporator is 60°C to 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com