System for purifying trichlorosilane by utilizing quadruple-effect coupled distillation and treatment method thereof

A technology for purifying trichlorosilane and rectification, which is applied to chemical instruments and methods, silicon compounds, halosilanes, etc. It can solve the problem that the purity of silicon trichloride does not reach the electronic level and cannot effectively solve the problem of raw material preheating and other issues to achieve the effects of saving consumption, reducing device costs and optimizing process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

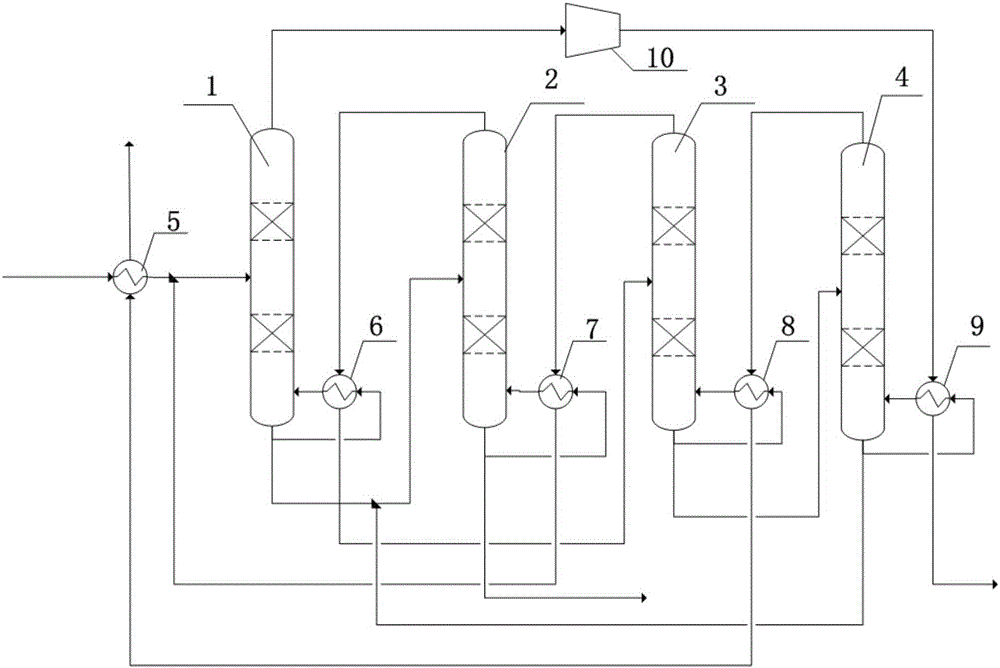

[0051] This embodiment provides a system for purifying trichlorosilane by four-effect coupled rectification, characterized in that the first light removal tower 1, the first light removal tower 2, the second light removal tower 3, the second light removal tower Weight removal tower 4, feed preheater 5, first weight removal tower reboiler 6, first weight removal tower reboiler 7, second weight removal tower reboiler 8, second weight removal tower reboiler 9 and a heat pump compressor 10; wherein, the top steam outlet of the first light removal tower 1 is connected to the light miscellaneous storage tank through the heat pump compressor 10 and the second heavy removal tower reboiler 9 successively, and the first light removal tower 1 The bottom material outlet is connected to the feed port of the first de-weight tower 2; the top steam outlet of the first de-weight tower 2 is connected to the feed port of the second de-light tower 3 through the first de-light tower reboiler 6 The...

Embodiment 2

[0054] The present embodiment provides the processing method of the system described in embodiment 1, and described method is as follows:

[0055] The raw materials to be treated are subjected to the first light removal treatment through the first light removal tower 1, and the light components obtained at the top of the tower are heated and heated by the heat pump compressor 10 in turn, and are combined with the second light removal tower reboiler 9 in the second light removal tower. The material at the bottom of tower 4 is extracted as light impurities after heat exchange, and part of the obtained heavy components is returned as reboiling gas, and part of them enters the first weight removal tower 2 for the first weight removal treatment;

[0056] Wherein, the temperature at the top of the first light removal tower 1 is 43-45°C, the temperature at the bottom of the tower is 57-60°C, the pressure at the top of the tower is 250-270kPa, and the pressure drop of the whole tower o...

Embodiment 3

[0065]This embodiment provides a treatment method for the system described in Example 1. In the method, except that the top temperature of the first light removal tower 1 is 40-43°C, the temperature of the bottom of the tower is 55-57°C, and the pressure at the top of the tower is It is 200~230kPa, the pressure drop of the whole tower of the first light removal tower 1 is less than 20kPa, and its reflux feed ratio is 1.0~2.0; The tower top temperature of the first light removal tower 2 is 60~63 ℃, the temperature 70-73°C, the top pressure of the tower is 300-330kPa, the pressure drop of the whole tower is less than 20kPa, and the reflux feed ratio is 1.0-2.0; the top temperature of the second light removal tower 3 is 75-77°C, The temperature is 85-87°C, the pressure at the top of the tower is 400-430kPa, the pressure drop of the whole tower is less than 50kPa, and the reflux feed ratio is 5.0-6.0; The temperature is 100-103° C., the temperature of the tower kettle is 700-730 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com