Microwave synthesis method of lithium magnesium silicate

A technology of microwave synthesis, magnesium lithium silicate, applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of insufficient uniformity of products, insufficient reaction, high cost, etc., and achieve good transparency, low cost, and short production time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A microwave synthesis method of lithium magnesium silicate, the specific steps are:

[0019] 1) Using magnesium oxide, lithium carbonate, and white carbon black as raw materials, the ratio of lithium, magnesium, and silicon is: Li:Mg:Si=1:9:16, and then add the An aqueous solution of 4 times the weight of the material is configured into a 20wt% suspension, the speed of the high-speed dispersing mixer is adjusted to 500 rpm for stirring, and NaOH is continuously added until the pH value is 13;

[0020] 2) Evenly disperse for 22 minutes; start the microwave device, set the microwave frequency to 2500MHZ, and synthesize for 6 hours;

[0021] 3) Turn off the microwave device and continue to react for 7 hours at 230°C and 2.3 MPa;

[0022] 4) Cool to normal temperature, wash with water in a centrifuge, centrifuge, dehydrate, dry and pulverize to obtain the finished product of lithium magnesium silicate.

Embodiment 2

[0024] A microwave synthesis method of lithium magnesium silicate, the specific steps are:

[0025] 1) Using magnesium oxide, lithium carbonate, and white carbon black as raw materials, the ratio of lithium, magnesium, and silicon is: Li:Mg:Si=1:9:16, and then add the An aqueous solution of 4 times the weight of the material is configured into a 20wt% suspension, the speed of the high-speed dispersing mixer is adjusted to 500 rpm for stirring, and NaOH is continuously added until the pH value is 10;

[0026] 2) Evenly disperse for 20 minutes; start the microwave device, set the microwave frequency to 2000MHZ, and synthesize for 6 hours;

[0027] 3) Turn off the microwave device and continue to react for 7 hours at 200°C and 2.6 MPa;

[0028] 4) Cool to normal temperature, wash with water in a centrifuge, centrifuge, dehydrate, dry and pulverize to obtain the finished product of lithium magnesium silicate.

Embodiment 3

[0030] A microwave synthesis method of lithium magnesium silicate, the specific steps are:

[0031] 1) Using magnesium oxide, lithium carbonate, and white carbon black as raw materials, the ratio of lithium, magnesium, and silicon is: Li:Mg:Si=1:9:16, and then add the An aqueous solution of 4 times the weight of the material is configured into a 20wt% suspension, the speed of the high-speed dispersing mixer is adjusted to 500 rpm for stirring, and NaOH is continuously added until the pH value is 15;

[0032] 2) Evenly disperse for 25 minutes; start the microwave device, set the microwave frequency to 3000MHZ, and synthesize for 6 hours;

[0033] 3) Turn off the microwave device and continue to react for 7 hours at 260°C and 2.0 MPa;

[0034] 4) Cool to normal temperature, wash with water in a centrifuge, centrifuge, dehydrate, dry and pulverize to obtain the finished product of lithium magnesium silicate.

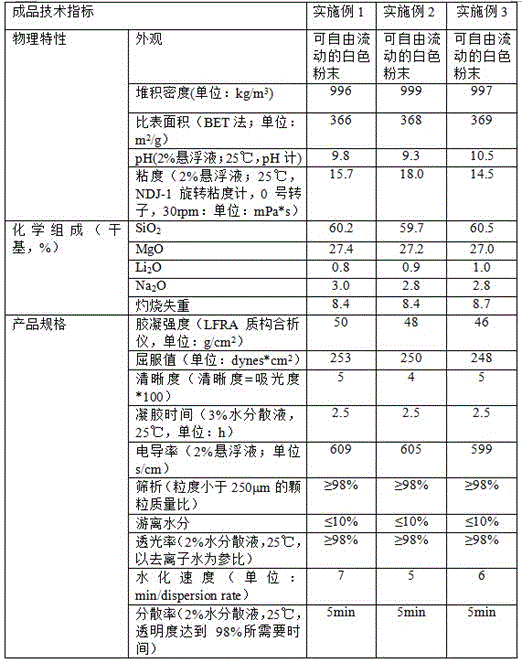

[0035] Above embodiment is made the technical indicator of magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com