Sludge drying system with high thermal driving force

A technology of sludge drying and driving force, which is applied in the direction of sludge treatment through temperature control, dehydration/drying/thickening sludge treatment, chemical instruments and methods, etc. Conduction resistance and other problems, to achieve the effect of delaying dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through examples.

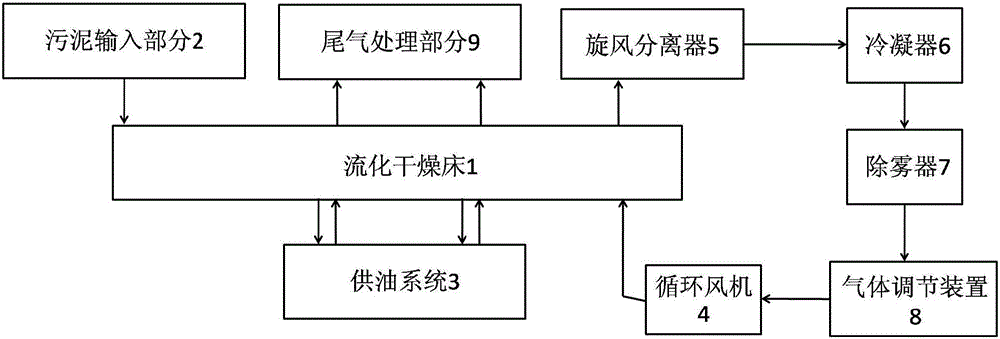

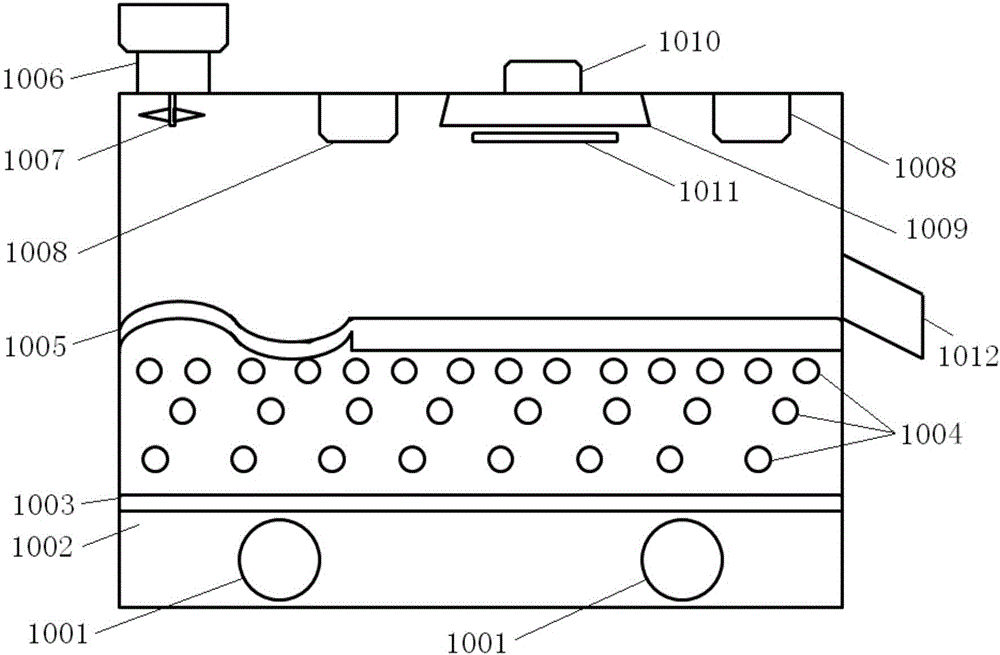

[0021] figure 1 It is a schematic diagram of the structure of the sludge drying system with high thermal driving force in the preferred embodiment of the present invention. by the figure 1 It can be seen that, with the fluidized drying bed 1 as the center, the sludge slurry with a moisture content of about 80% after mechanical preliminary dehydration is pumped into the fluidized drying bed 1 by the sludge input part 2 along the screw feed channel. The granulation, heating and water removal are carried out in the drying bed; the heat transfer oil as the heat transfer medium is heated by the combustion furnace, and then is input from the oil supply system 3 to the heat exchange tube in the fluidized drying bed 1 to provide heat for heating and drying , and then recirculated back to the oil supply system 3; the circulating gas is sent into the fluidized dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com