Novel high-stability heat supply mechanism for sludge drying equipment

A technology of sludge drying and high stability, which is applied in dehydration/drying/concentrated sludge treatment, etc., and can solve problems such as environmental impact, low drying efficiency, random stacking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

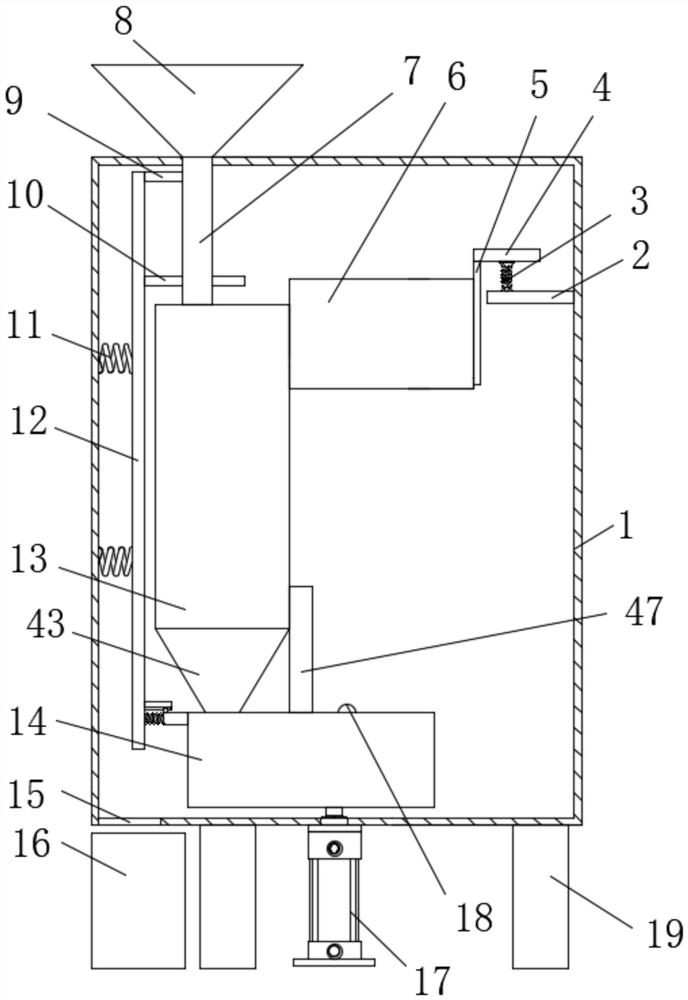

[0033]refer to Figure 1-8 , a new type of high-stability heating mechanism for sludge drying equipment, including a box body 1, the inside of the box body 1 is fixedly connected with a drying box 13, and the inside of the drying box 13 is provided with a device for drying sludge Drying assembly, the top of the drying box 13 is provided with a connected feeding pipe 7, the top of the feeding pipe 7 extends to the outside of the box body 1 and is fixedly connected with a connected feeding funnel 8, the inside of the box body 1 A blanking assembly for blanking is provided, one side of the drying box 13 is fixedly connected with a connected connecting pipe 22, and the inner wall of one side of the box body 1 is fixedly connected with a fixed box 6, and the connecting pipe 22 communicates with the fixed box 6 , the interior of the fixed box 6 is provided with a reflux assembly for material reflux, the bottom of the drying box 13 is fixedly connected with a connected discharge funn...

Embodiment 2

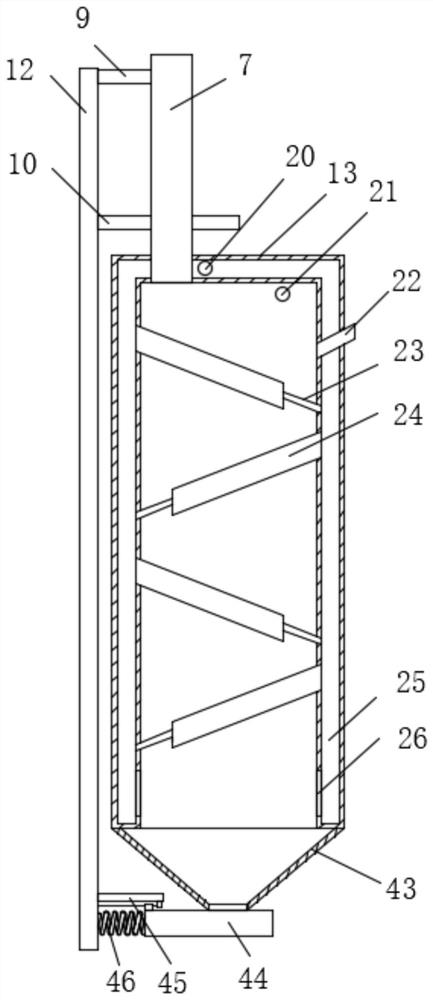

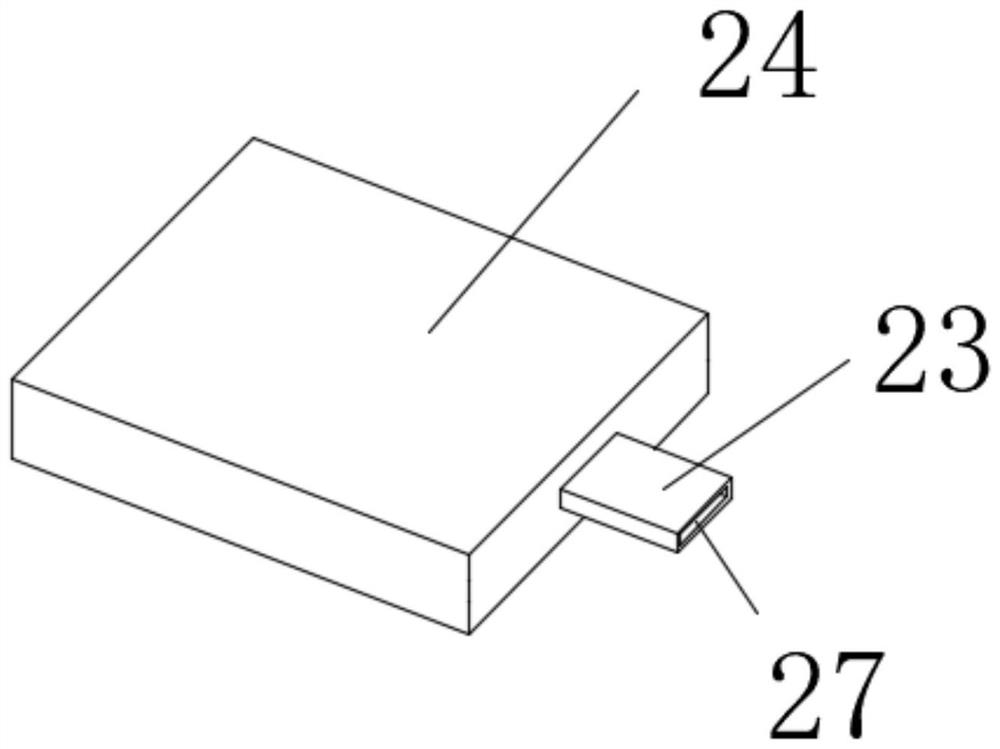

[0035] refer to Figure 1-8 , a new type of high-stability heating mechanism for sludge drying equipment, including a box body 1, the inside of the box body 1 is fixedly connected with a drying box 13, and the inside of the drying box 13 is provided with a device for drying sludge The drying assembly, the drying assembly includes an inner cavity 25 provided inside the drying box 13, and the inner walls on both sides of the drying box 13 are provided with air inlets 26 communicating with the inner cavity 25, and the inside of the drying box 13 is provided with There are a plurality of second slant plates 24 and first slant plates 23, and the first slant plates 23 and the second slant plates 24 are used in conjunction with each other. Through the air vent 27, the inner wall of one side of the box body 1 is fixedly connected with a rectangular box 35, and the two sides of the rectangular box 35 are respectively fixedly connected with a connected air outlet pipe 20 and an air inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com