A kind of electromagnetic absorbing concrete and its preparation method

A technology of electromagnetic wave absorption and concrete, which is applied in the interdisciplinary field of building material science and electromagnetic science, can solve the problems of low wave absorption efficiency, poor mechanical properties, and narrow effective frequency band, etc., and achieve the effect of increasing the space action area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

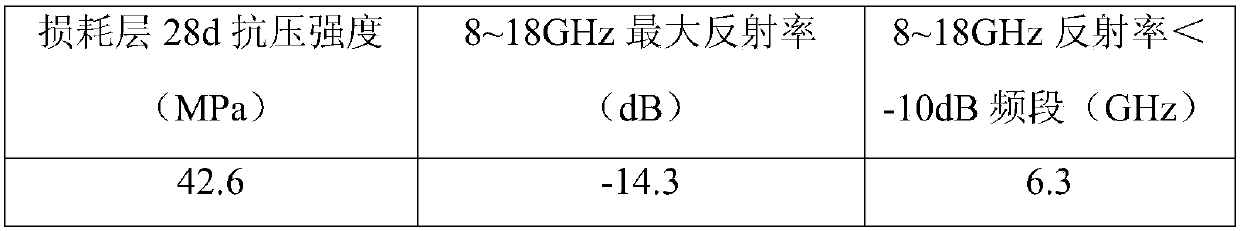

Embodiment 1

[0026] An electromagnetic wave-absorbing concrete, the volume percentages of wave-absorbing functional ceramsite (aggregate) and wave-absorbing cement slurry are respectively 40% and 60%; The percentage of volume is 15%, and its preparation method includes the following steps:

[0027] 1) Preparation of wave-absorbing functional ceramsite: the clay, titanium dioxide, magnesium carbonate and sodium sulfate are weighed in mass percentages of 60%, 30%, 5% and 5% respectively, and are mixed, granulated and fired in sequence (Rise to 1280°C at a rate of 20°C / min, calcinate at a constant temperature for 10 minutes, and cool down to room temperature with the furnace) to obtain wave-absorbing functional ceramsite with a cylinder compressive strength of 7.3 MPa, a particle size of 2 to 5 mm, and an apparent density of 1.45g / cm 3 .

[0028] 2) Pretreatment of wave absorbing functional ceramsite: Calculate the mass of the wave absorbing functional ceramsite according to the volume cont...

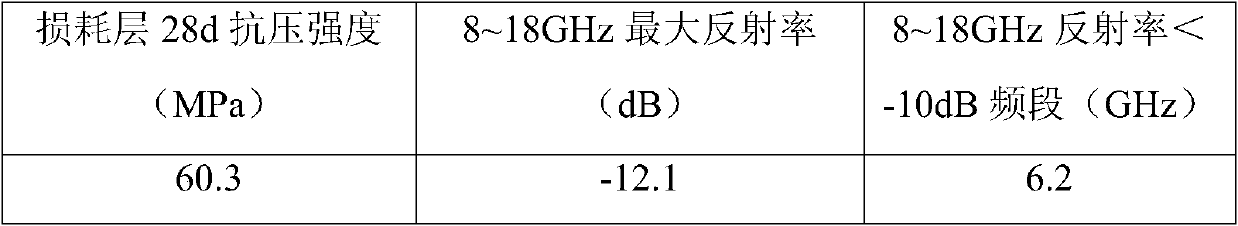

Embodiment 2

[0037] An electromagnetic wave-absorbing concrete, the volume percentages of wave-absorbing functional ceramsite (aggregate) and wave-absorbing cement slurry are respectively 70% and 30%; wherein the volume percentage of nano-titanium dioxide (wave absorbing agent) in the volume of wave-absorbing cement slurry is: 3%, and its preparation method includes the following steps:

[0038] 1) Preparation of wave-absorbing functional ceramsite: the clay, titanium dioxide, magnesium carbonate and sodium sulfate are weighed in mass percentages of 85%, 10%, 3% and 2%, respectively, and are mixed, granulated and fired in sequence (Rise to 1120°C at a rate of 5°C / min, calcinate at a constant temperature for 45 minutes, and cool down to room temperature with the furnace) to obtain wave-absorbing functional ceramsite with a cylinder compressive strength of 9.8MPa, a particle size of 5-10mm, and an apparent density of 1.37 g / cm 3 .

[0039] 2) Pretreatment of wave absorbing functional ceram...

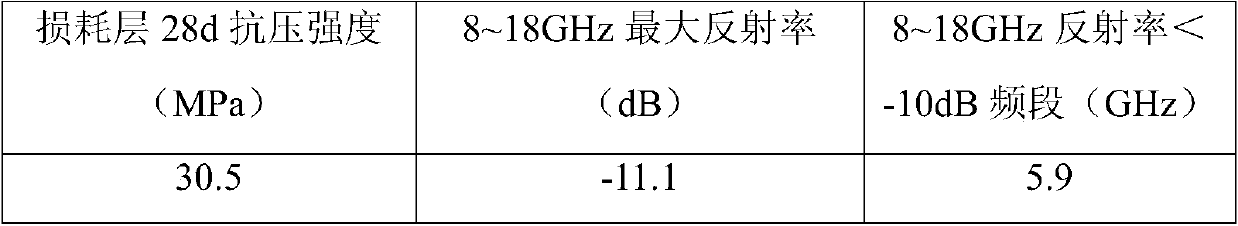

Embodiment 3

[0048] An electromagnetic wave-absorbing concrete, the volume percentages of wave-absorbing functional ceramsite (aggregate) and wave-absorbing cement slurry are respectively 50% and 50%; wherein the high-structure carbon black (wave-absorbing agent) accounts for 50% of the volume of the wave-absorbing cement slurry. The percentage is 8%, and its preparation method includes the following steps:

[0049] 1) Preparation of wave-absorbing functional ceramsite: the clay, titanium dioxide, magnesium carbonate and sodium sulfate are weighed at 77%, 20%, 2% and 1% by mass, and mixed, granulated and fired in sequence (Rise to 1200°C at a rate of 10°C / min, calcinate at a constant temperature for 30 minutes, and cool down to room temperature with the furnace) to obtain wave-absorbing functional ceramsite with a cylinder compressive strength of 9.9MPa, a particle size of 8-12mm, and an apparent density of 1.42 g / cm 3 .

[0050] 2) Pretreatment of wave absorbing functional ceramsite: Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com