Formula and construction method of concrete

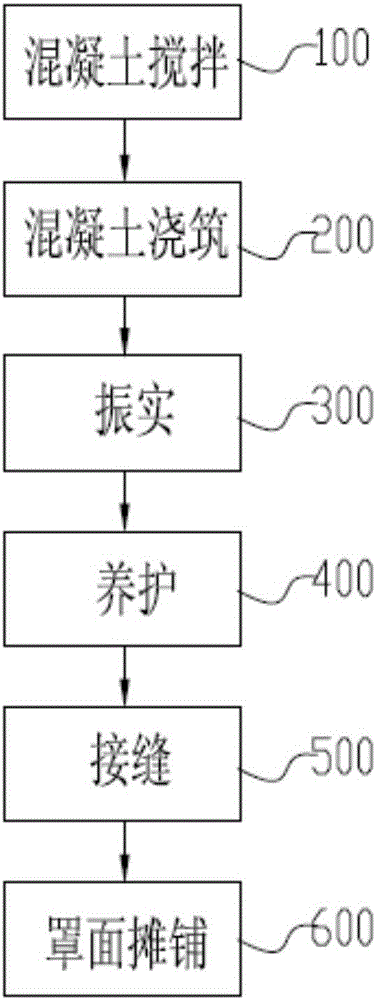

A construction method and concrete technology, applied in the field of concrete, can solve the problems that water permeability and structural strength cannot have both, structural strength reduction, durability reduction, etc., and achieve the effects of prolonging water permeability aging, various construction methods, and facilitating popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A concrete formula, which comprises the following components by weight: 80 parts of cement, 20 parts of 48-mesh fly ash, 30 parts of 10-mesh waste concrete slag, 300 parts of crushed stone, 30 parts of water, cement concrete reinforcing agent 6 parts, 5 parts of superplasticizer, and 5 parts of retarder.

[0028] Among them, cement and fly ash are used as gelling agents, and the fly ash particles have a porous structure. When the 48-mesh fly ash and the 10-mesh waste concrete slag are coagulated at a weight ratio of 0.67, the fly ash adheres to the concrete slag. On the other hand, continuous lower-diameter first-order pores can be formed between fly ash particles, while waste concrete slag and crushed stones are used as concrete aggregates, and the gaps between crushed stones are filled with cement, fly ash and waste concrete slag. Filling, but due to the larger diameter and amount of gravel, secondary pores with larger diameters can still be formed, and the water perm...

Embodiment 2

[0030] This embodiment is basically the same as Example 1, the difference being: 90 parts of cement in the formula, 25 parts of 60-mesh fly ash, 30 parts of 10-mesh waste concrete slag, 320 parts of gravel, 35 parts of water, 7 parts of cement concrete reinforcing agent 6 parts, 6 parts of superplasticizer, and 6 parts of retarder.

[0031] Among them, cement and fly ash are used as gelling agents, and the fly ash particles have a porous structure. When the 60-mesh fly ash and the 10-mesh waste concrete slag coagulate at a weight ratio of 0.83, the fly ash adheres to the concrete slag. On the other hand, continuous lower-diameter first-order pores can be formed between fly ash particles, while waste concrete slag and crushed stones are used as concrete aggregates, and the gaps between crushed stones are filled with cement, fly ash and waste concrete slag. Filling, but due to the larger diameter and amount of gravel, secondary pores with larger diameters can still be formed, an...

Embodiment 3

[0033] This embodiment is basically the same as Example 1, the difference is: 100 parts of cement in the formula, 30 parts of 70-mesh fly ash, 30 parts of 10-mesh waste concrete slag, 340 parts of crushed stone, 40 parts of water, 8 parts of cement concrete reinforcing agent 7 parts, 7 parts of superplasticizer, and 7 parts of retarder.

[0034] Among them, cement and fly ash are used as gelling agents, and the fly ash particles have a porous structure. When the 70-mesh fly ash and the 10-mesh waste concrete slag are coagulated at a weight ratio of 1.00, the fly ash adheres to the concrete slag. On the other hand, continuous lower-diameter first-order pores can be formed between fly ash particles, while waste concrete slag and crushed stones are used as concrete aggregates, and the gaps between crushed stones are filled with cement, fly ash and waste concrete slag. Filling, but due to the larger diameter and amount of crushed stone, secondary pores with larger diameters can st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com