A new type of three-dimensional shock-isolation bearing

A seismic isolation bearing, three-dimensional technology, applied in the field of bridge engineering and construction engineering, can solve the problem of no shock absorption function, and achieve the effect of simple production, reducing seismic action and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

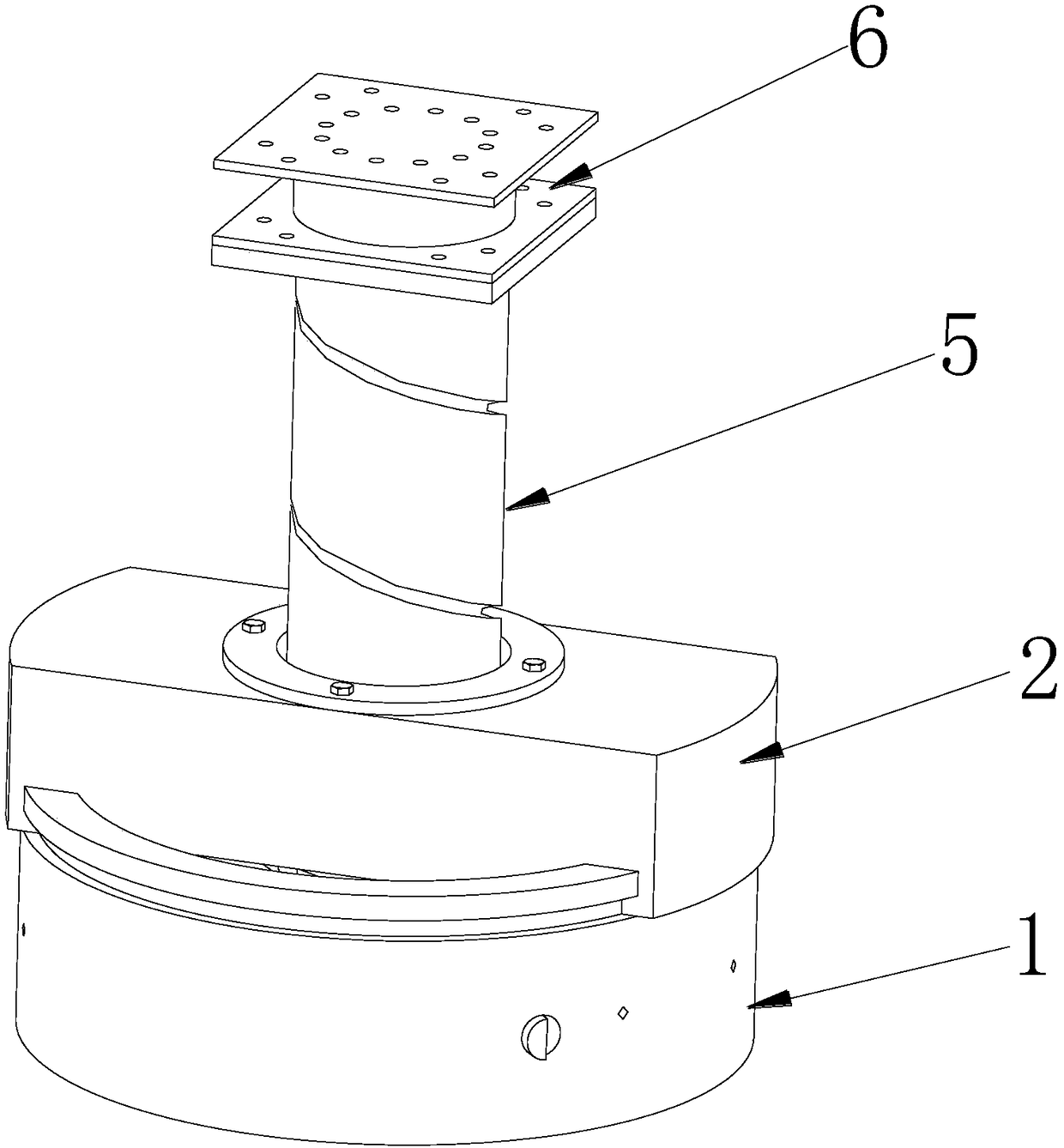

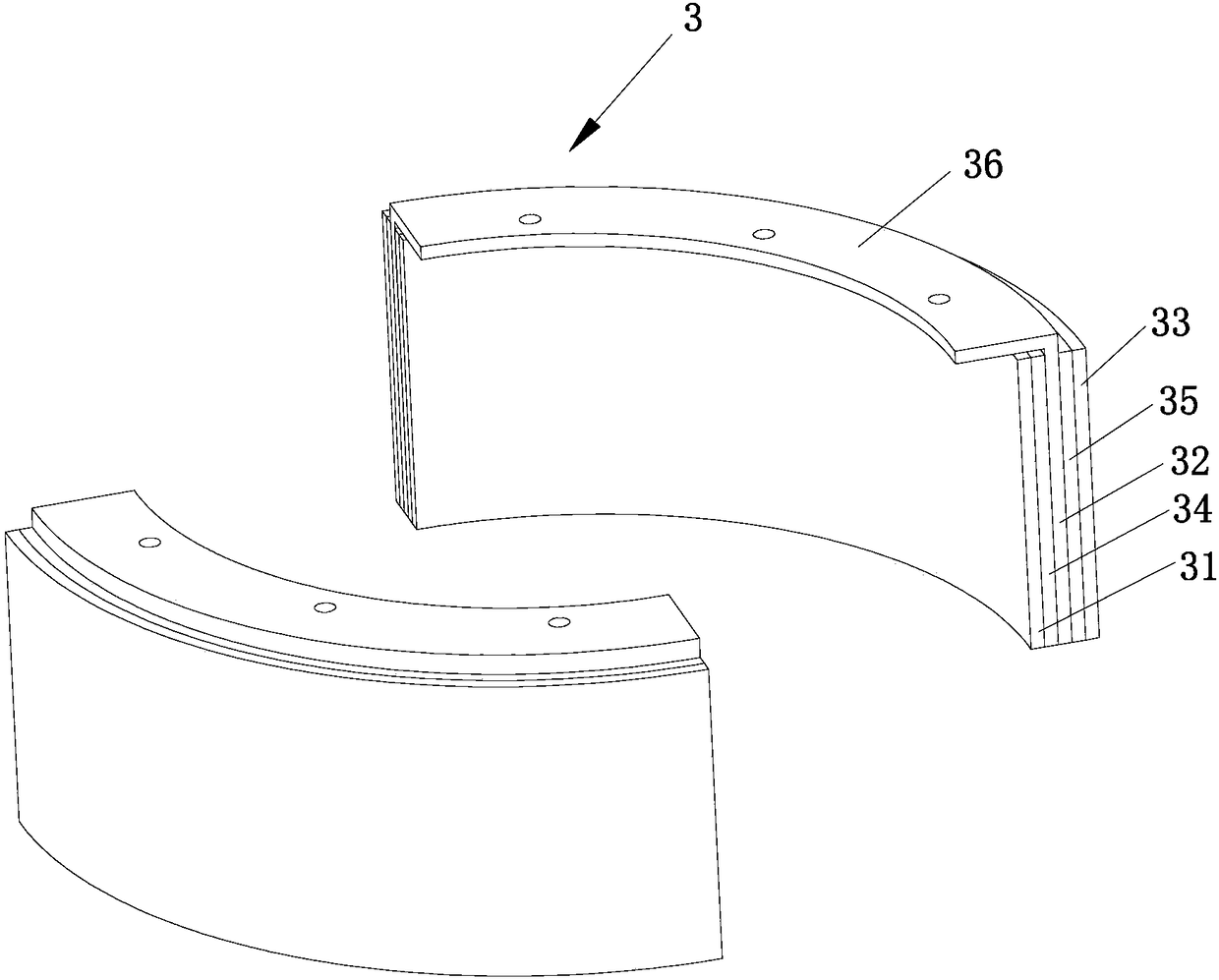

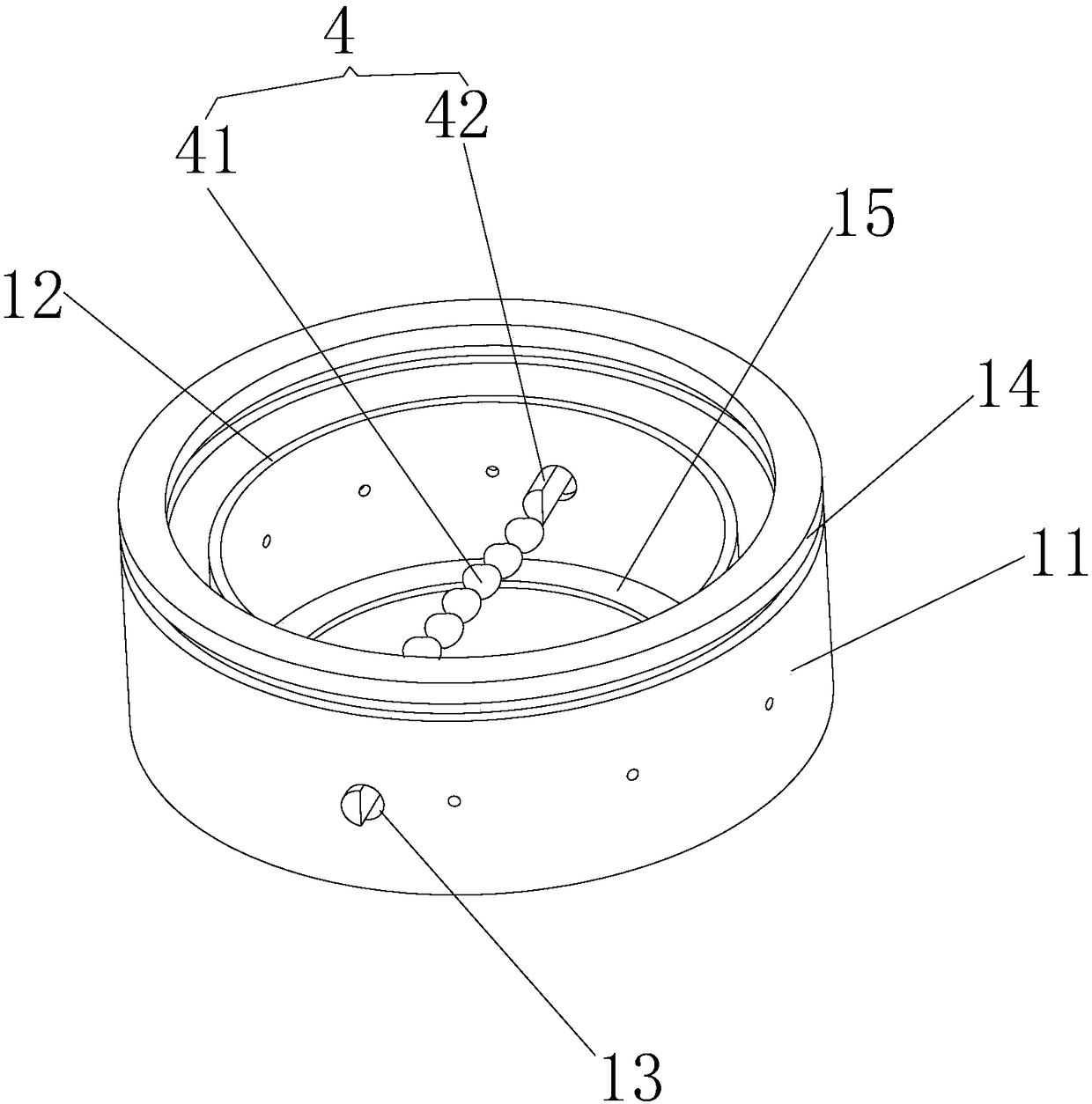

[0030] Such as Figure 1-6 As shown, this embodiment provides a new type of three-dimensional seismic isolation bearing, including a steel drum 1 and a horizontal beam 2 rotatably arranged on the steel drum 1, and a rotating rubber bearing assembly is arranged in the steel drum 1 3. The rotating rubber bearing assembly 3 is connected to the lower part of the horizontal beam 2 and can rotate under the drive of the horizontal beam 2. The steel drum 1 is also provided with a rubber bearing assembly that prevents rotation in a static state 3. The rotating spring pin 4 also includes a ball screw 5, the lower end of which is connected to the upper part of the horizontal beam 2, and the upper end of the ball screw 5 is provided with a horizontal shock-isolating member 6.

[0031] During use, the mechanisms of the novel three-dimensional shock-isolation bearing of the present invention are connected sequentially and installed between the upper shock-isolation structure and the lower s...

Embodiment 2

[0048] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the vertical shock-isolating member of this embodiment may include multiple, in this case, it also includes a horizontal Transition platform 7, the bottom of this horizontal transition platform 7 is connected with a number of ball screws 5, and the vertical vibration isolation members can be 3 or more, respectively fixedly connected to the bottom of this horizontal transition platform 7, forming an overall three-dimensional Shock-isolation mounts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com