Steel arch splicing system of area L2 of heading machine

A steel arch frame and roadheader technology, which is applied in shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of fast, safe, efficient construction, low work efficiency, and high risk factor that are not suitable for roadheaders, so as to improve construction safety Coefficient, reduce human labor, reduce the effect of cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

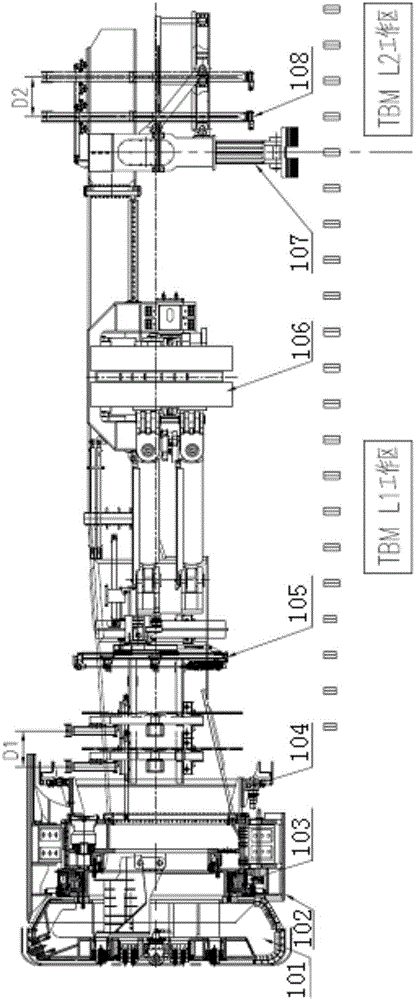

[0029] Such as figure 1 As shown, it is a side view of erecting the steel arch assembly system of the present invention in the L2 area behind the L1 area of the existing roadheader; wherein, the cutter head 101, the shield 102 and the main drive 103 are sequentially arranged on the steel arch in the L1 area In front of the frame 104, and behind the steel arch 104 in the L1 area, a bolt drill 105, a shoe 106, and a rear support 107 in the L1 area are sequentially arranged, and the steel arch 108 in the L2 area is arranged behind the rear support 107. The spacing D1 of the steel arches 104 in the L1 area depends on the number of slots in the shoe 106, while the spacing D2 of the steel arches 108 in the L2 area can be adjusted arbitrarily.

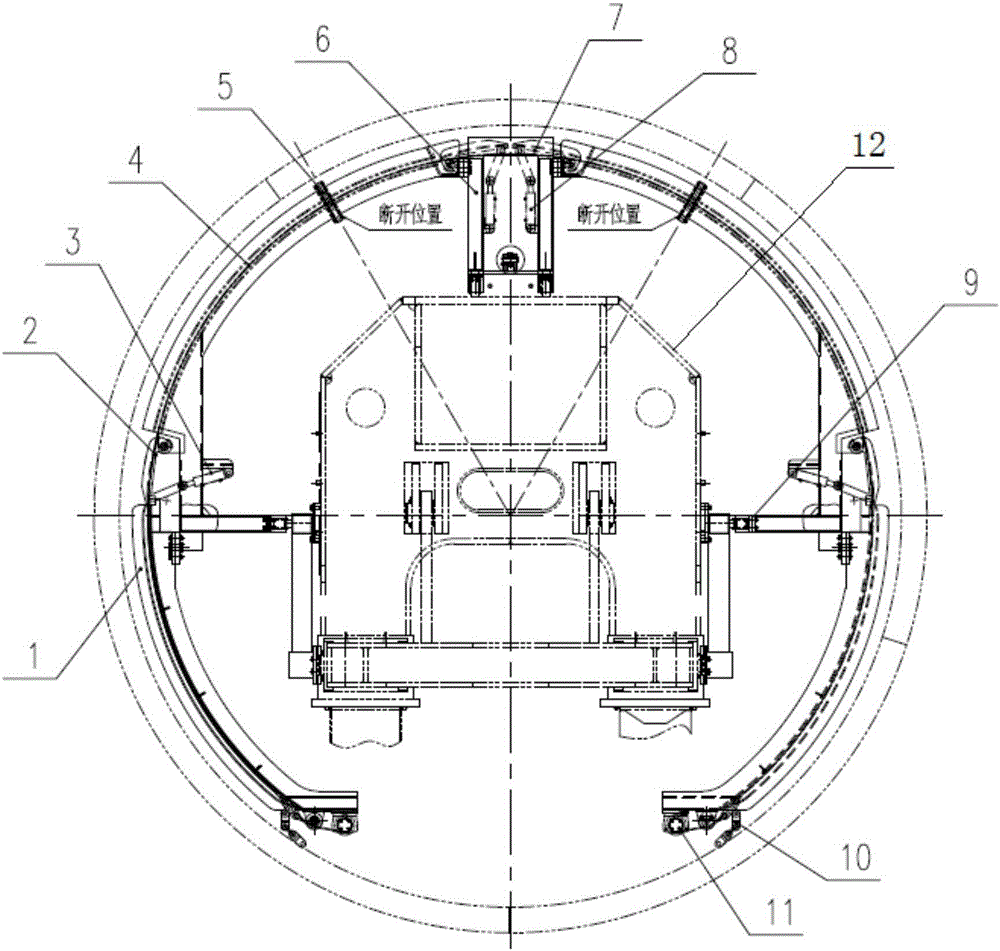

[0030] Another example figure 2 As shown, the steel arch assembly system in the L2 area of the roadheader according to the present...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap