Engine brake method for vehicle retardance

A technology of engine braking and engine, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of fuel nozzle tip burnout, insufficient, high engine temperature, etc., to eliminate high load and high exhaust temperature, improve The effect of reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

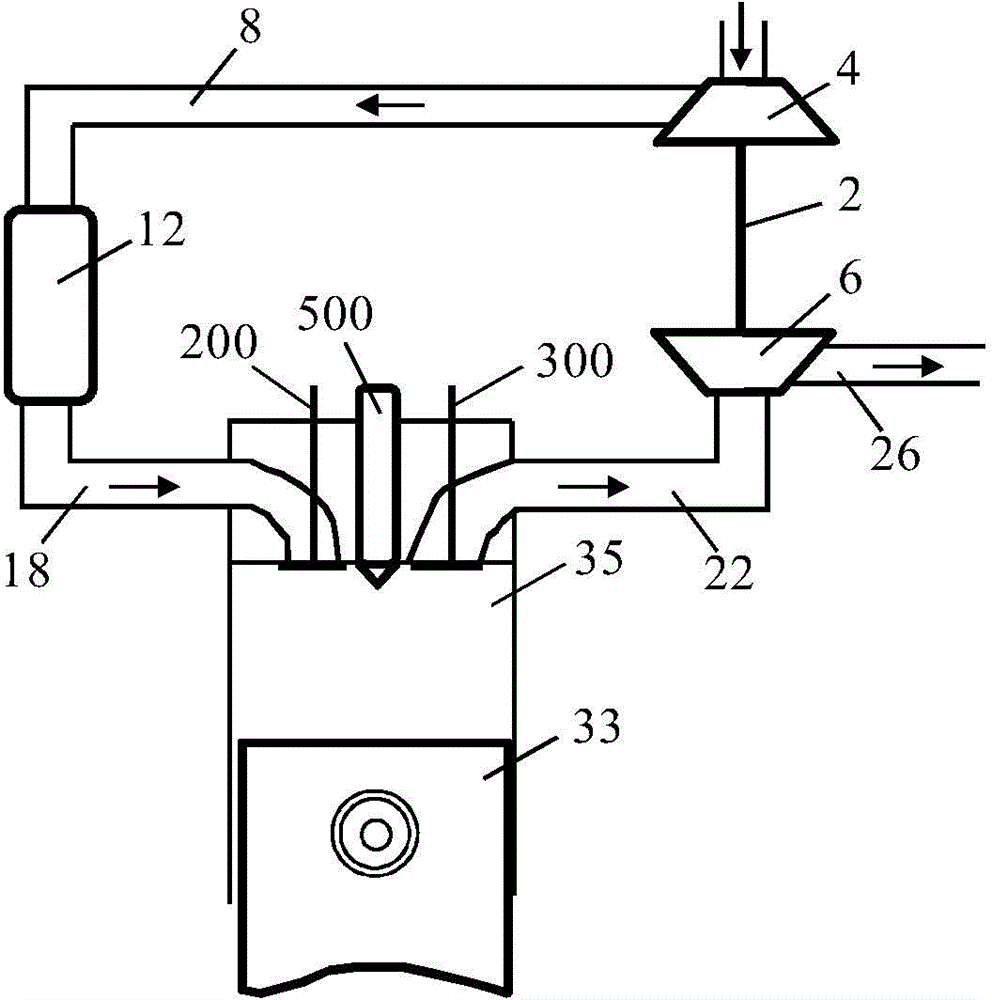

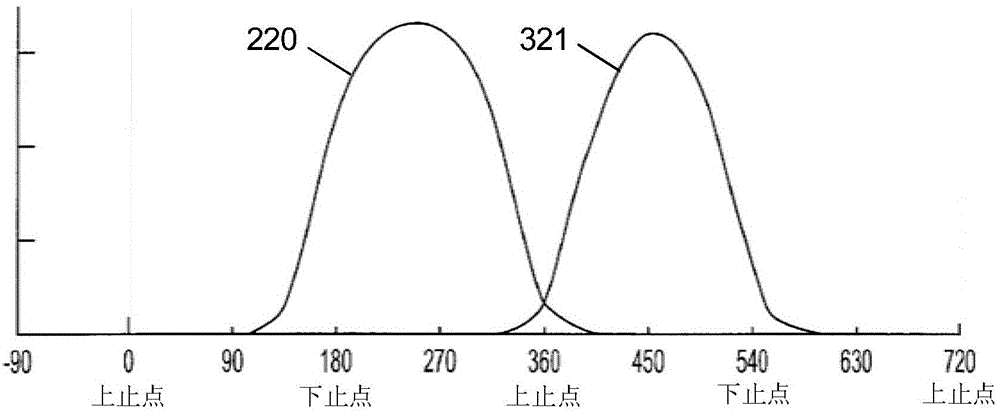

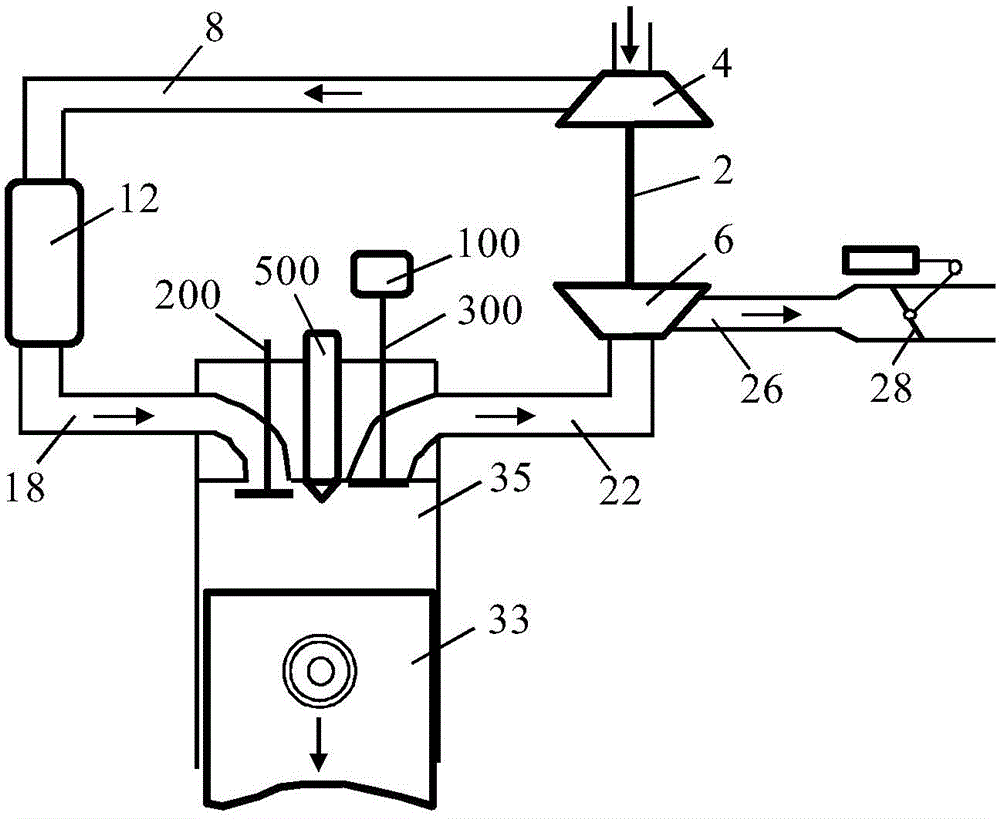

[0081] figure 1 and figure 2 Used to describe the ignition operation of a conventional four-stroke engine. General engines have multiple cylinders. For example, the engine on a commercial vehicle is an inline six-cylinder diesel engine. But for brevity, figure 1 and figure 2 Only one engine cylinder and the movement of that cylinder's valve in one cycle are shown. The piston 33 of the engine performs periodic motions up and down in the cylinder 35 . As mentioned above, each cycle of motion of a four-stroke engine includes an intake stroke, a compression stroke, an expansion (or working) stroke, and an exhaust stroke. During the intake stroke, figure 1 The engine piston 33 in the cylinder 35 starts from the exhaust top dead center ( figure 2 360° in the middle) to the intake bottom dead center ( figure 2 540°) movement in the engine, the intake valve 200 of the engine opens, resulting in figure 2 The intake valve profile 321 in the intake valve introduces air into...

Embodiment 2

[0089] The difference between the second embodiment of the engine braking method of the present invention and the first embodiment is that not only fuel is injected into the engine cylinder in this embodiment, but also other gaseous or liquid media, such as air and water. wait. Although the injected air and water cannot be burned, it is possible to increase the pressure in the cylinder and the resistance of the piston to the top dead center, thereby increasing the braking power of the engine. If the temperature in the cylinder is high enough, the sprayed water may turn into steam and increase the pressure in the cylinder.

[0090] The working process of this embodiment is similar to that of the first embodiment, and will not be repeated here.

Embodiment 3

[0092] The difference between this embodiment and the above-mentioned first or second embodiment is that this embodiment does not directly inject medium into the cylinder of the engine, but injects air into the exhaust pipe of the engine, and then adjusts the exhaust pressure of the engine and opens the exhaust pipe. The door, which forces the air injected into the exhaust pipe into the cylinders of the engine.

[0093] The operation process of the engine braking method of this embodiment can be through Figure 6 to illustrate. Compared with the first embodiment, this embodiment adds an air injection mechanism, including an air compressor 41 (the diesel engine of a general commercial vehicle is equipped with an air compressor), an air injection pipeline 43 and an air injection valve 45 . The air injection pipeline 43 communicates with an outlet of the air compressor and the exhaust pipe 22 of the engine, and the air injection valve 45 is arranged on the outlet of the air comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com