Magnetic field shielding cover of cusped magnetic field thruster

A tangent magnetic field and thruster technology, applied in the field of electric thrusters, can solve the problems of satellite electronic equipment interference, excessive induction strength, etc., and achieve the effect of improving the working temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

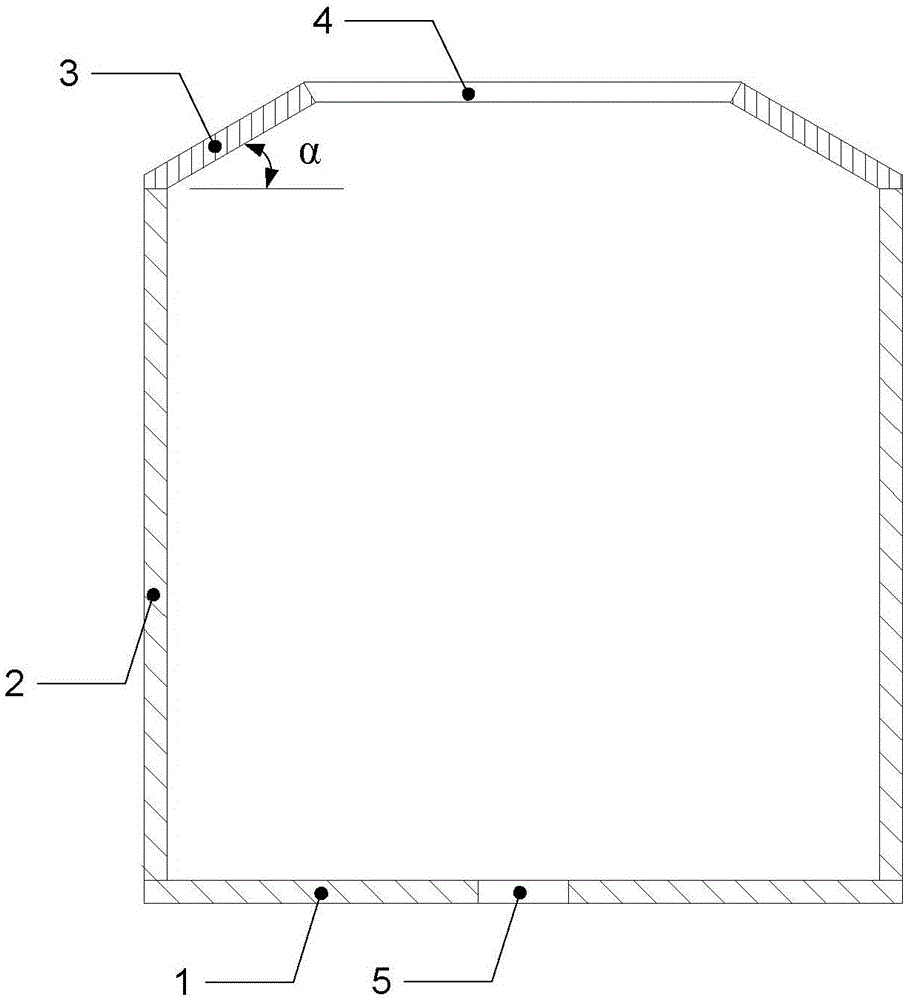

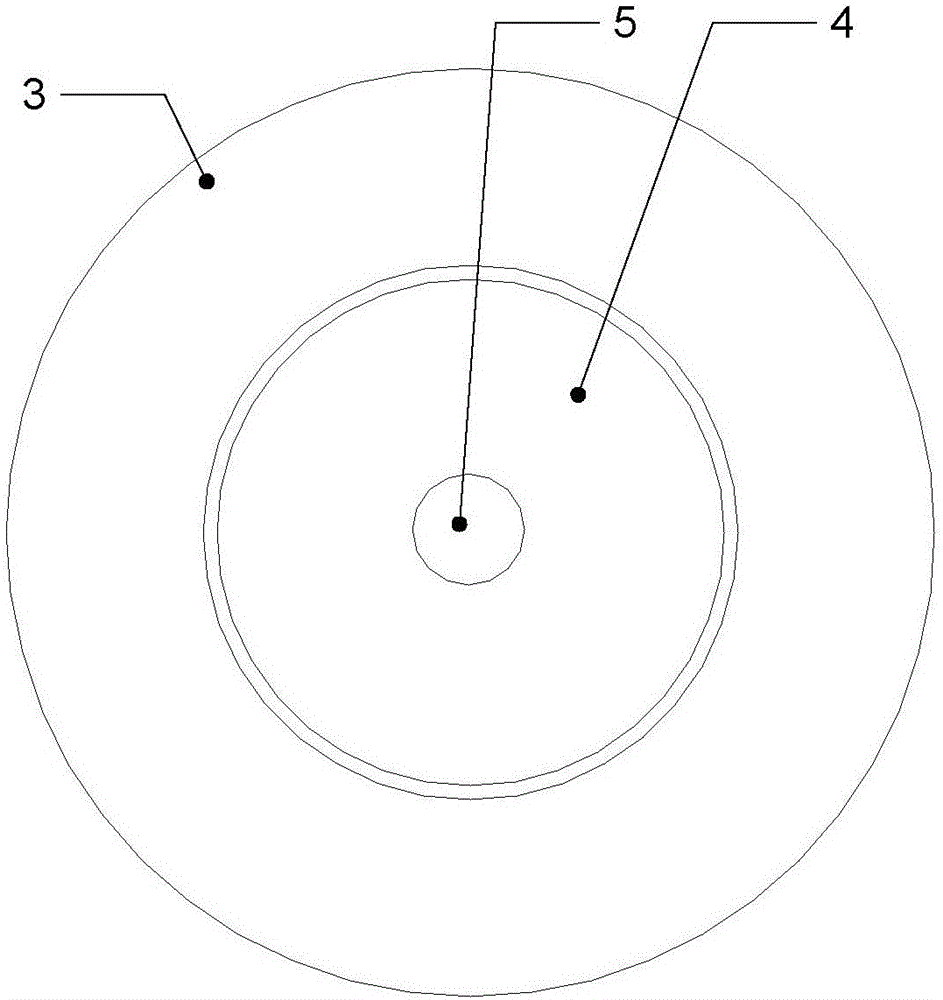

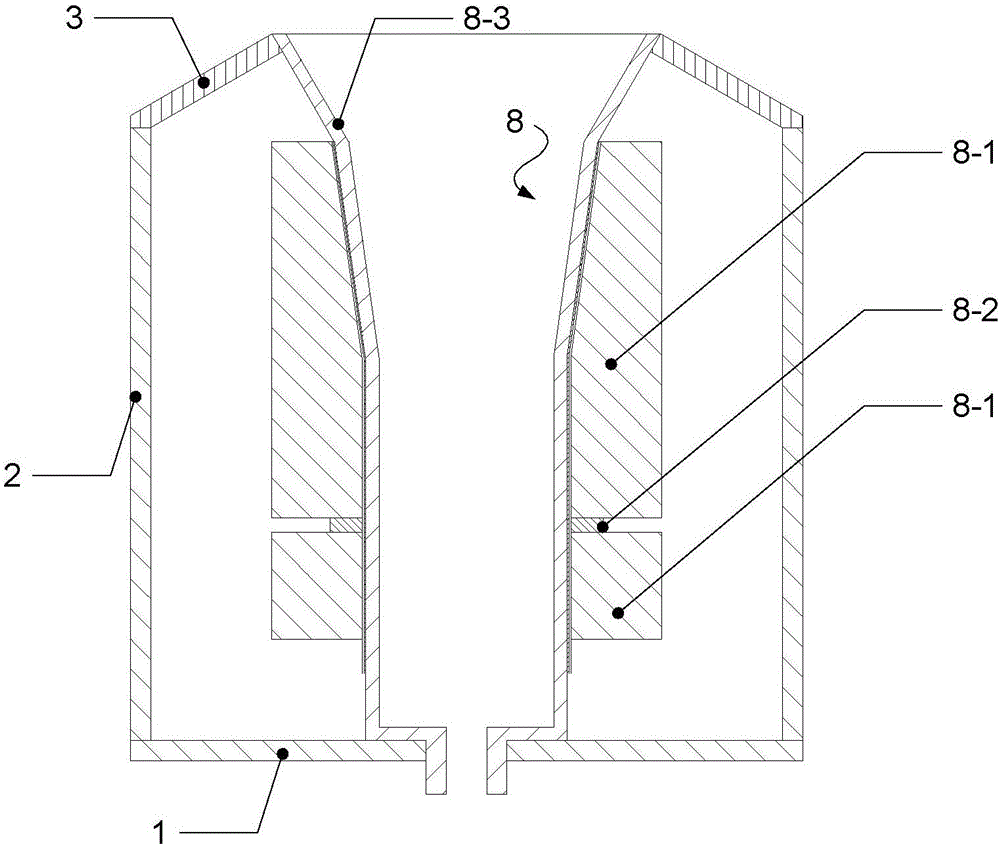

[0026] Specific implementation mode one: the following combination Figure 1 to Figure 7 Describe this embodiment, the magnetic field shield of the cusp magnetic field thruster described in this embodiment is as follows figure 1 As shown, there is no fixing device in this embodiment, the bottom plate 1 and the cylinder body 2 are integrally processed into an upwardly open drum structure, the upper opening is welded with a cover 3, the cover 3 is a frustum-shaped cylindrical structure, the large port of the cover 3 is connected with the cylinder The upper port of the body 2 is welded together, and the small port of the cover 3 is used as the ceramic outlet mounting hole 4. Installed on the cusp magnetic field thruster 8, the shielding cover is used as its shell, the outlet of the ceramic discharge channel 8-3 is fixed with the ceramic outlet mounting hole 4, and the entrance of the ceramic discharge channel 8-3 is at the 5 places of the ceramic inlet mounting hole, which will b...

specific Embodiment approach 2

[0029] Specific implementation mode two: the following combination Figure 8 to Figure 15 This embodiment will be described. This embodiment will further describe the first embodiment. Four fixed feet 6 are installed on the same horizontal plane as the outer circle of the bottom plate 1, and the thruster is fixed at a fixed position outside through the positioning installation hole 7.

[0030] The magnetic field distribution after installing the fixed foot 6 is as follows Figure 11 As shown, compared with the distribution of magnetic induction intensity without fixed feet, the external magnetic field distribution of the thruster is seriously affected, and the magnetic induction intensity of the corresponding external parts has been significantly enhanced.

[0031] Moreover, in this embodiment, the four fixed legs 6 are evenly distributed along the circumference, so as to reduce the influence of the fixed legs 6 on the overall shielding effect.

[0032] A specific example is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com