Pressure compensation device and method for detecting whether compensated device leaks oil

A pressure compensation and compensation device technology, applied in transmission parts, by measuring the acceleration and deceleration rate of fluid, using liquid/vacuum for liquid tightness measurement, etc. Complicated and other problems, to achieve the effect of easy operation, simple structure, convenient and quick pressure compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

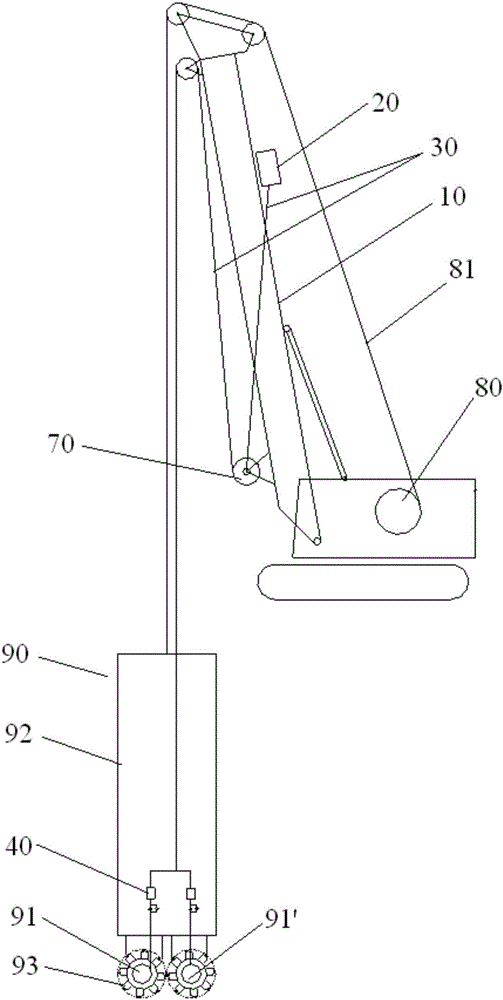

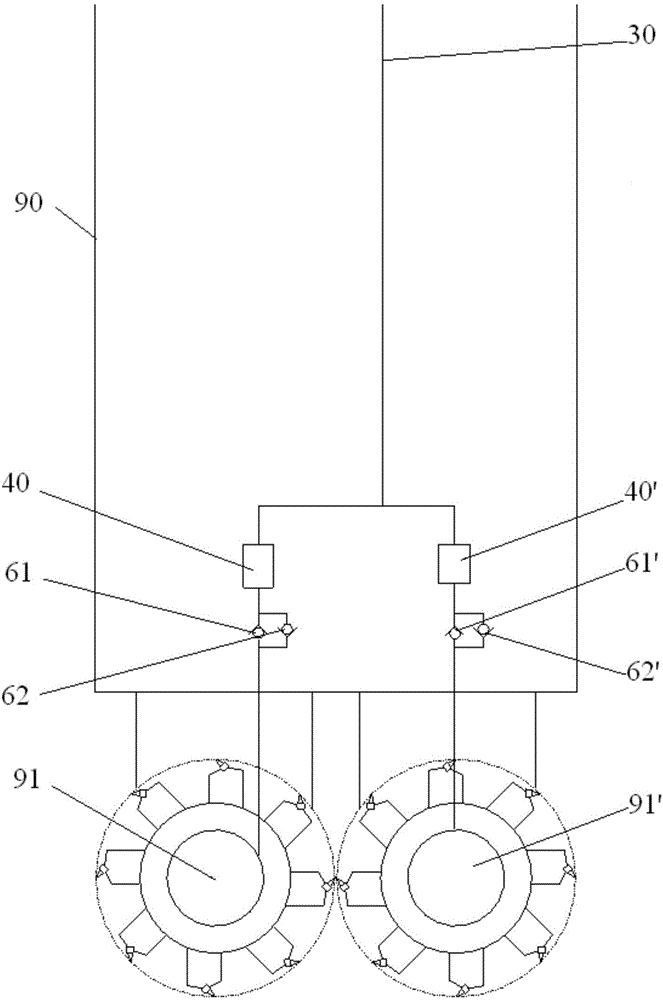

[0046] This specific embodiment discloses a pressure compensating device, which is connected with a transmission device working in water or mud, and is used for pressure compensation of the transmission device. Such as figure 1 and figure 2 As shown, the pressure compensating device in this embodiment is connected with a slot milling machine 90 for foundation construction. The slot milling machine 90 includes a transmission device 91, 91', a frame 92 and a milling wheel 93. The whole slot milling machine 90 is hoisted 80 and steel wire rope 81 will sink into the mud environment for operation, therefore, it is necessary to carry out pressure compensation to the transmission device 91 of the milling machine 90.

[0047] Such as figure 1 and figure 2 As shown, the pressure compensating device disclosed in this specific embodiment includes: a bracket 10; a liquid storage tank 20, fixed on the bracket 10, located above the working liquid level where the transmission device 91 ...

Embodiment 2

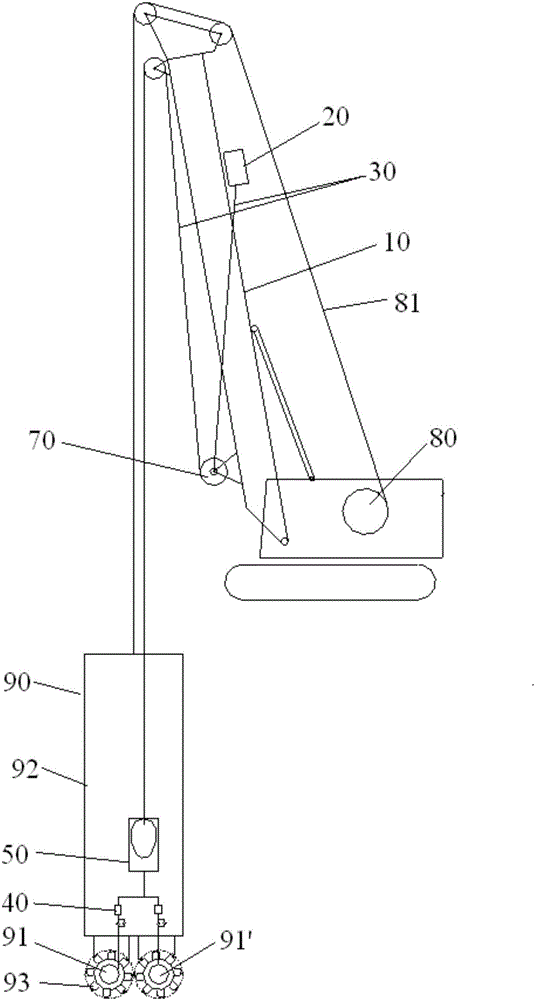

[0058] Since the density of the gear oil is lower than that of the mud, as the depth increases, the pressurized value generated by the height difference between the liquid storage tank and the construction liquid level will gradually decrease, and finally it will be less than the external pressure. Therefore, Embodiment 1 It is only applicable to the situation that the construction depth of the groove milling machine 90 is relatively shallow.

[0059] The pressure compensation device disclosed in the second embodiment is basically the same as the first embodiment, the difference is that the pressure compensation device in the second embodiment also includes a two-liquid separation box 50, by setting the two-liquid separation box 50, the pressure compensation can be made The device is applicable to the situation that the construction depth of the groove milling machine 90 is relatively deep.

[0060] Such as image 3 and Figure 4 As shown, the two-liquid separation box 50 in...

Embodiment 3

[0068]The invention also discloses a method for detecting whether the compensated device is leaking oil, the compensated device is a transmission device connected to the pressure compensating device, comprising the steps of:

[0069] S10: the liquid storage tank delivers liquid to the transmission device through the pipeline;

[0070] S20: monitor the flow of the liquid in the pipeline through a flowmeter;

[0071] S30: judging whether the flow rate monitored by the flowmeter exceeds the preset flow rate;

[0072] S40: If yes, the compensated device leaks oil, and sends out a first alarm message; if not, the compensated device does not leak oil or the oil leak is not serious;

[0073] S50: Monitoring the internal and external pressure difference of the compensated device through the pressure sensor;

[0074] S60: judging whether the pressure difference monitored by the pressure sensor exceeds a first preset pressure difference (usually 2-4 ar);

[0075] S70: If yes, send ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com