Low-NOx (nitrogen oxide) flat flame heat storage type burner using graded burning technique

A staged combustion, regenerative technology, applied in burners, combustion methods, combustion types, etc., can solve the problems of not achieving the effect of reducing NOx emissions, aggravating atmospheric pollution, destroying flame integrity, etc., to improve heating The effect of quality, increased productivity, reduced fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

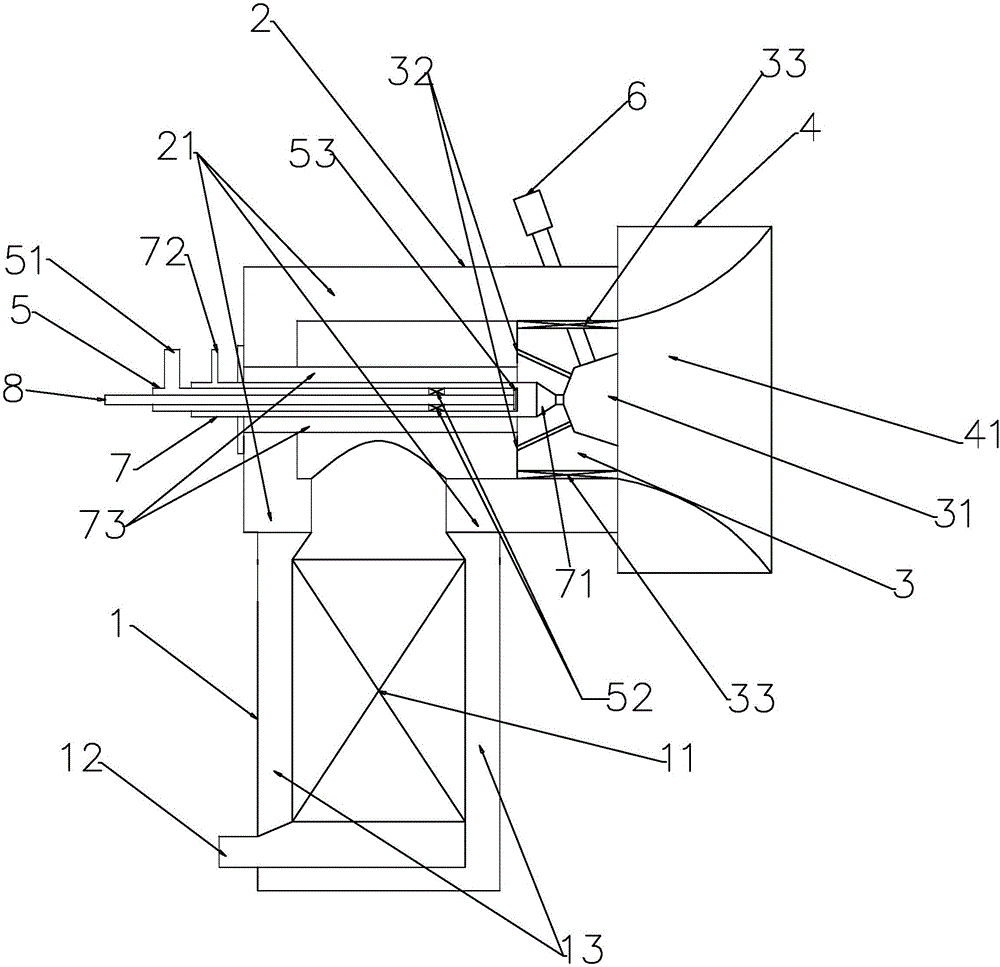

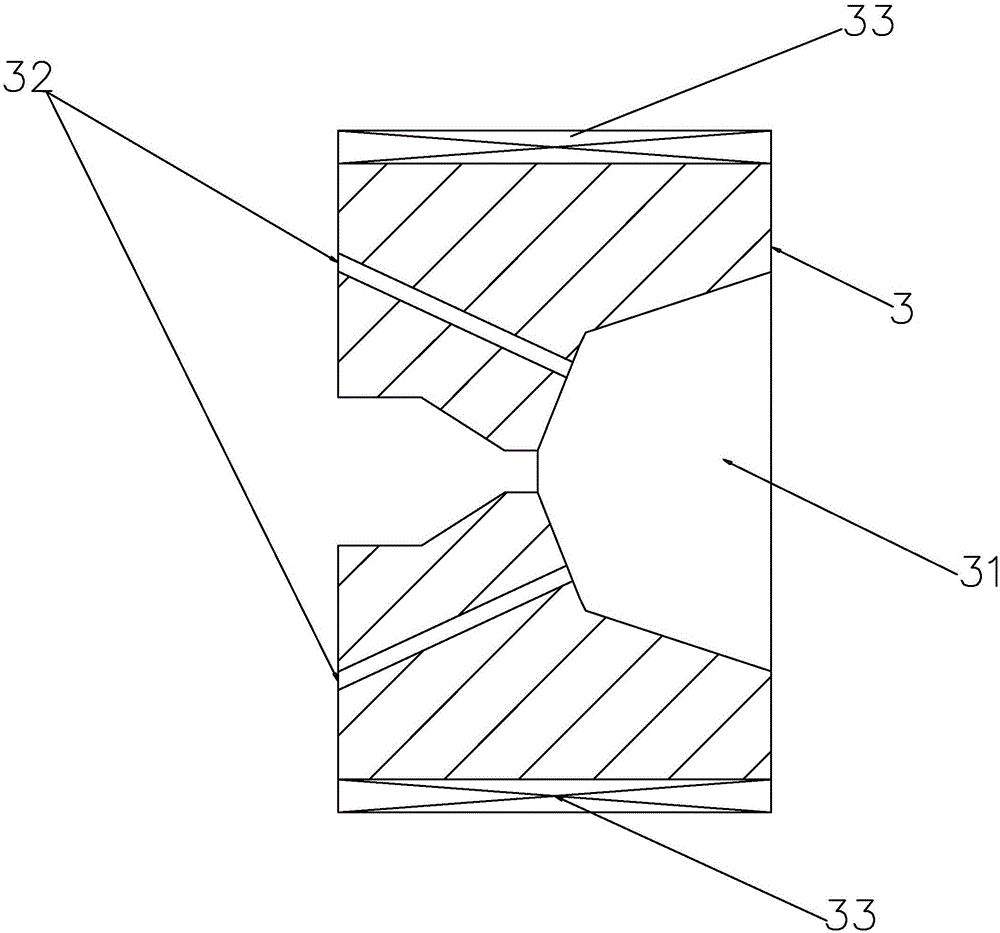

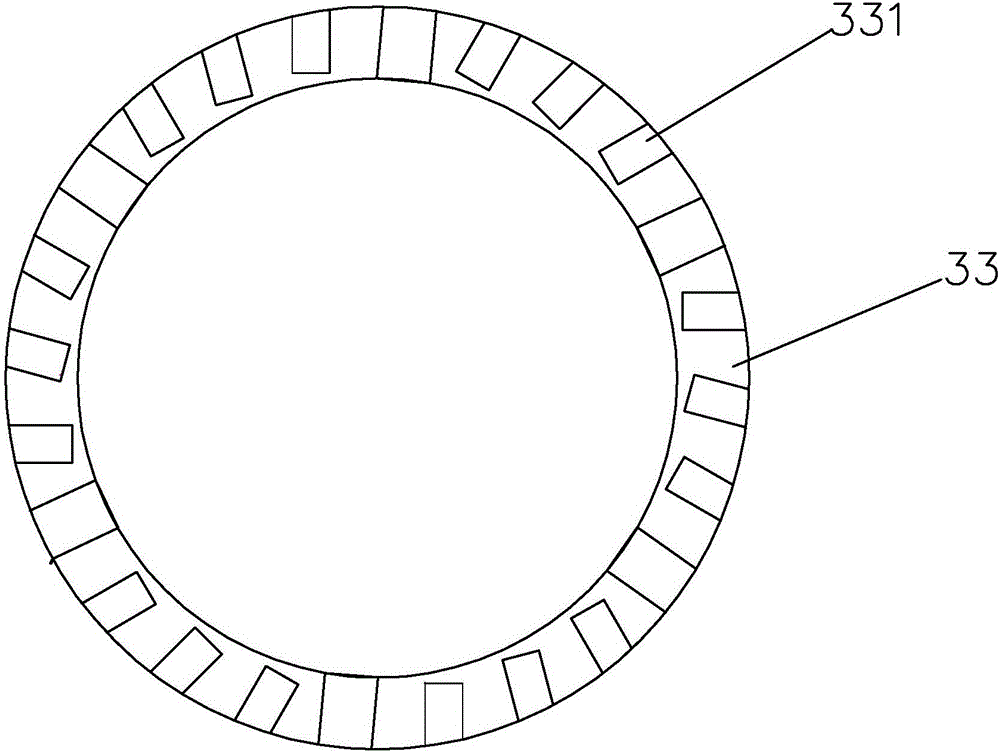

[0016] see Figure 1-4 As shown, the present invention relates to a low NOx flat-flame regenerative burner with staged combustion technology, including a heat storage box 1 with a heat storage body 11 inside, a burner housing 2 communicated with the heat storage box 1, and a The air-fuel mixing head 3 in the burner housing 2, the flat-flame burnt brick 4 arranged outside the air-fuel mixing head 3, the gas pipe 5, and the ignition burner 6, the air-fuel mixing head 3 is provided with a combustion chamber 31, flat There is a flat flame combustion chamber 41 inside the flame-fired brick 4, an air port 12 is connected to one end of the heat storage box 1, and one end of the gas pipe 5 is set in the burner housing 2 and communicated with the combustion chamber 31, and the other end is provided with a gas inlet 51. The ignition burner 6 communicates with the combustion chamber 31, and the combustion chamber 31 communicates with the flat flame combustion chamber 41. The air-fuel mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com