Pressure sintering furnace with rapid cooling function

A pressure sintering and rapid cooling technology, which is applied in the field of pressure sintering furnaces, can solve the problems of simple cooling methods, slow convective heat exchange, and low cooling efficiency, and achieve the effects of ensuring cycle efficiency, improving production efficiency, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

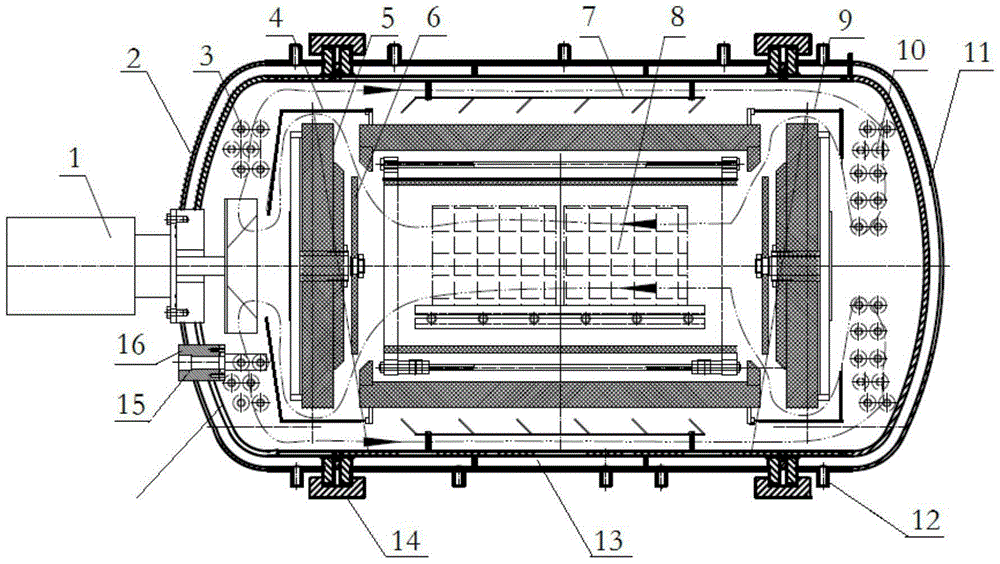

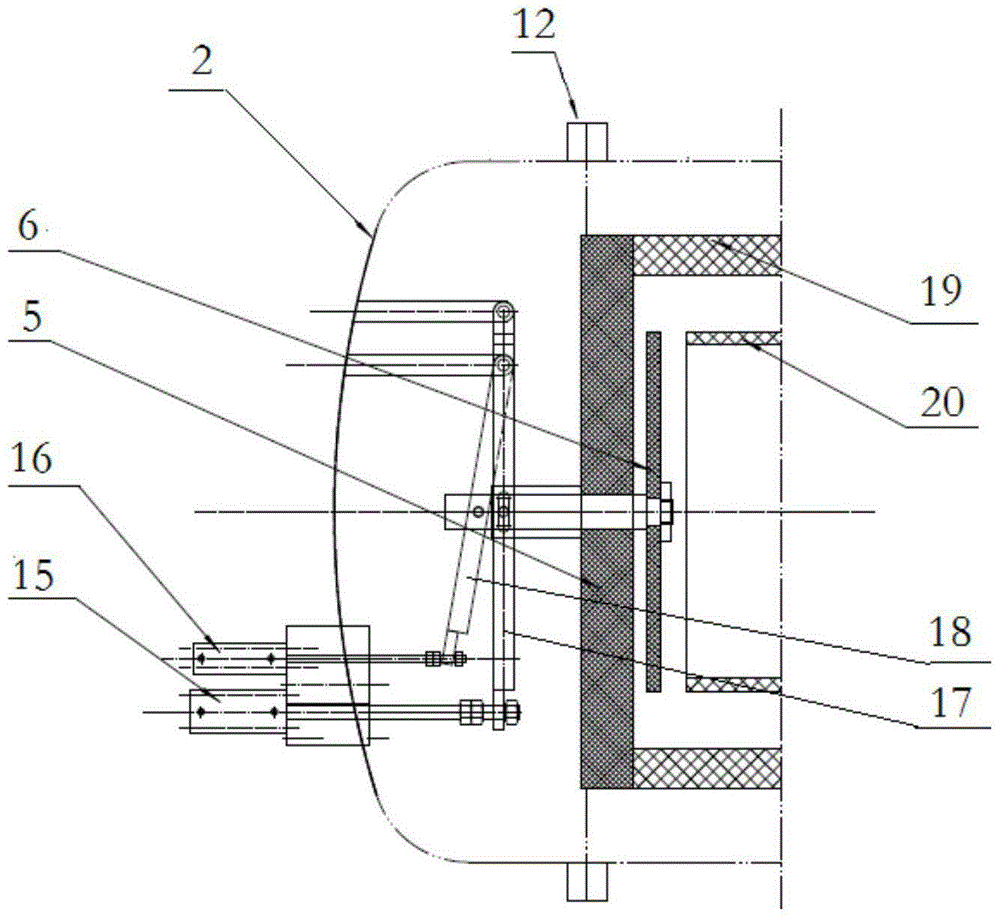

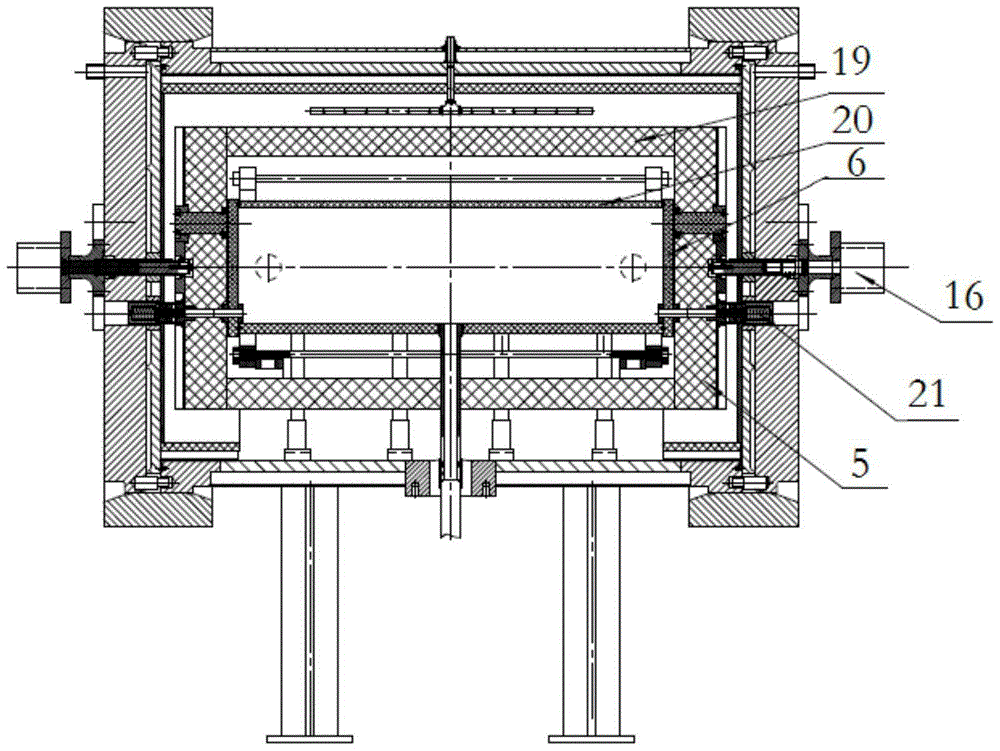

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 , figure 2 As shown, the present invention comprises blower fan 1, furnace door, furnace body, heat exchanger, gas deflector cover, airflow deflector 7, cooling water inlet and outlet pipe 12, furnace shell water jacket 13, heat preservation door cylinder 15 and material box The door cylinder 16 and the insulation door 5, material box door 6, insulation tube 19 and high-temperature product area 8 arranged in the furnace body; the high-temperature product area 8 is supported by a graphite base plate and a graphite support column installed in the furnace body. A material box 20 is arranged in the high-temperature product area 8 .

[0026]Fan 1 is a high-power water-cooled fan with a water-cooling jacket and cooling water inlet and outlet pipes. The fan 1 is provided with blades. The furnace door is a front furnace do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com