Large sample-loading amount multifunctional deep sea environment sample frame, test device and test method

A deep-sea environment and test device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of limited types and quantities, easy bottom suction, and high requirements for test sites, so as to achieve simple and compact design structure and reduce deployment time , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

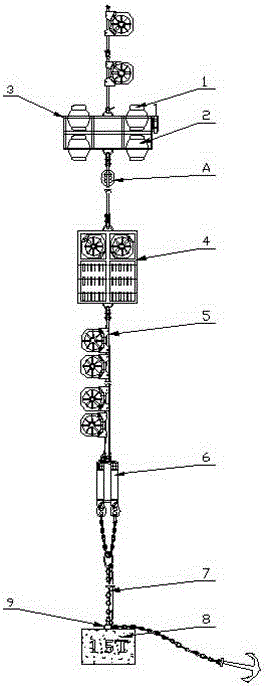

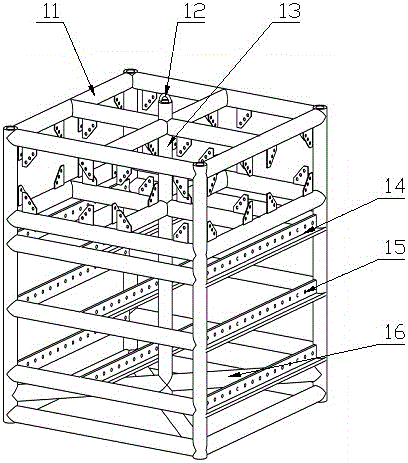

[0041] Attached below Figure 1-6 , a kind of large sample capacity multifunctional deep-sea environment sample frame, test device and test method of the present invention are described in detail below.

[0042] as attached figure 1 As shown, the present invention provides a multifunctional deep-sea environmental test device with a large sample load, which adopts a "near-bottom suspension" structure, that is, the sample frame 4 is fixed at a distance of 10-50 meters from the seabed by buoyancy for exposure testing , so that the sample frame 4 will not be affected by seabed silt, and can also avoid the occurrence of the bottom-absorbing phenomenon of the frame of the deep-sea test device in the United States. Its structure is to connect the floating body, the sample frame 4, the releaser 6 and the sinker anchor 9 from top to bottom by using the connecting rope 5 alone or with a titanium shackle, and the connecting rope 5 is preferably a Kevlar rope. in:

[0043] (1) Floating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com