Diode Anode Structures, Vertical Diodes, and Lateral Diodes

An anode structure and diode technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of increasing the forward turn-on voltage, and achieve the effect of reducing the forward turn-on voltage, improving the efficiency, and solving the forward turn-on voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

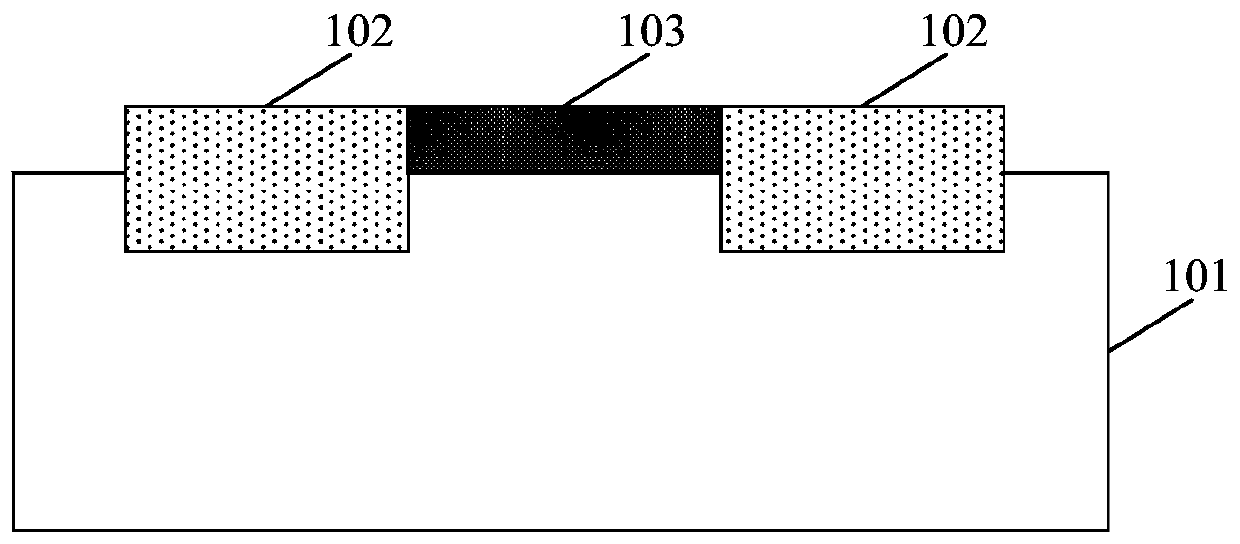

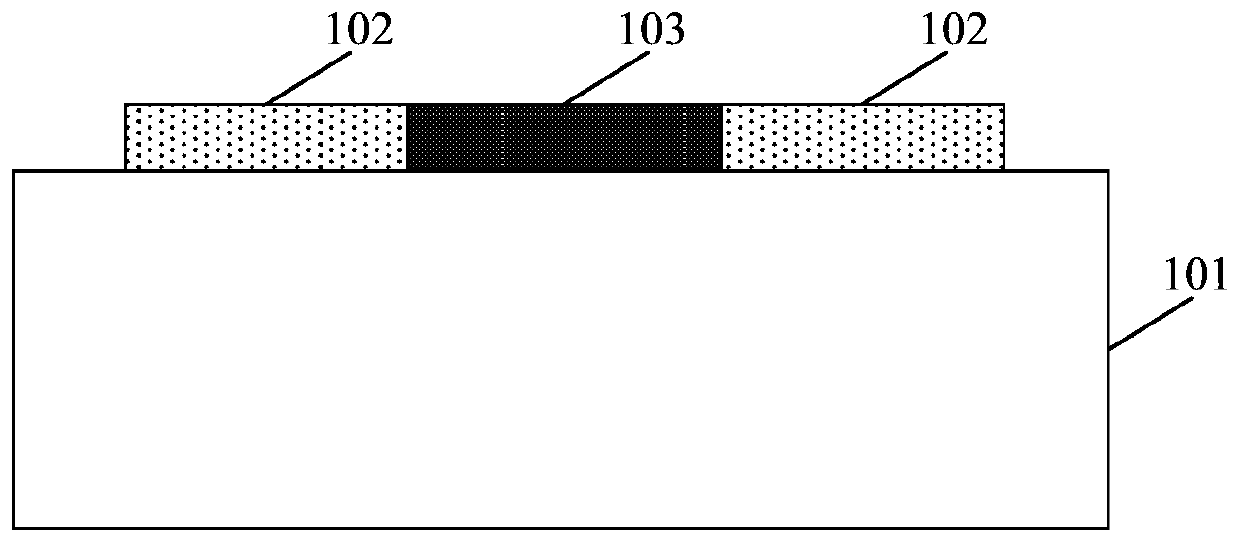

[0046] Figure 1a and Figure 1b Both are schematic cross-sectional structure diagrams of a diode anode structure provided in Embodiment 1 of the present invention. Specifically, the diode anode structure provided in the embodiment of the present invention includes two different types of Schottky metal layers. Such as Figure 1a and Figure 1b As shown, the diode anode structure may include:

[0047] semiconductor layer 101;

[0048] At least two first Schottky metal layers 102 are located on the semiconductor layer 101 and form Schottky contacts with the semiconductor layer 101 to obtain a first Schottky barrier height;

[0049] At least one second Schottky metal layer 103 is located on the semiconductor layer 101 and between the first Schottky metal layers 102 to form a Schottky contact with the semiconductor layer 101 to obtain a second Schottky barrier height.

[0050] Specifically, such as Figure 1a As shown, a groove structure corresponding to the first Schottky meta...

Embodiment 2

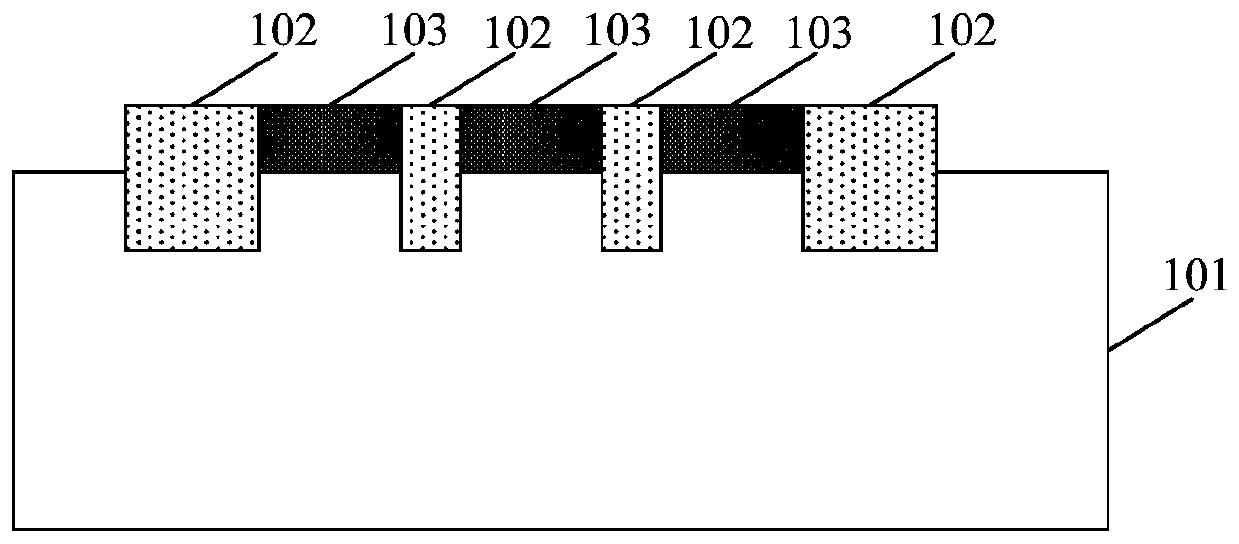

[0059] Figure 2a , Figure 2b , Figure 2c and Figure 2d Both are structural schematic diagrams of a diode anode structure provided in Embodiment 2 of the present invention. This embodiment is based on Embodiment 1 and adjusted on the basis of Embodiment 1. Specifically, the diode anode structure provided by the embodiment of the present invention includes multiple first Schottky metal layers 102 and multiple second Schottky metal layers 103 .

[0060] Such as Figure 2a as shown, Figure 2a The number of first Schottky metal layers 102 located on the semiconductor layer 101 is four, and the number of second Schottky metal layers 103 located on the semiconductor layer 101 and between the first Schottky metal layers 102 The number is three. In practical applications, the number and distance between the first Schottky metal layer 102 and the second Schottky metal layer 103 can be adjusted according to the requirements of forward turn-on current and reverse leakage current...

Embodiment 3

[0065] Figure 3a and Figure 3b Both are schematic cross-sectional structural diagrams of a diode anode structure provided in Embodiment 3 of the present invention. This embodiment is based on the above-mentioned embodiments and is optimized on the basis of the above-mentioned embodiments. Specifically, in the diode anode structure provided by the embodiment of the present invention, a potential barrier adjustment region is formed between the first Schottky metal layer 102 and the semiconductor layer 101 .

[0066] Such as Figure 3a As shown, a potential barrier adjustment region 104 is formed between the first Schottky metal layer 102 and the semiconductor layer 101 , and the potential barrier adjustment region 104 is disposed corresponding to the first Schottky metal layer 102 . Figure 3a In the shown diode anode structure, a groove structure is formed between the semiconductor layer 101 and the first Schottky metal layer 102 , so the barrier adjustment region 104 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com