Preparing method of boxthorn leaf freeze-dried powder

A technology of wolfberry leaves and freeze-dried powder, which is applied in food drying, food science, food preservation, etc., can solve the problems of limited deep processing, development and application of wolfberry leaves, and monotonous forms, and achieves long-term storage, convenient transportation, and guaranteed nutrition The effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

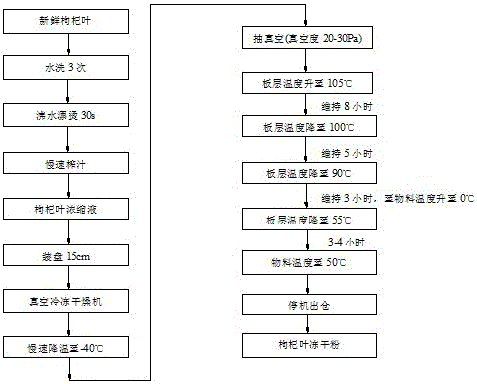

[0013] Such as figure 1 As shown, a method for preparing Lycium barbarum leaf freeze-dried powder of the present invention is characterized in that the method comprises the following steps: 1) Preparation step of Lycium barbarum leaf concentrate

[0014] Fresh wolfberry leaves→Wash 1-3 times→Blanching for 20-50 seconds→Squeeze the juice at a slow speed→Collect the concentrated wolfberry leaf juice→Store in a freezer at -20°C - -40°C for later use;

[0015] 2) Freeze sublimation step Thaw the concentrated wolfberry leaf juice, mix it and move it into the loading tray of the vacuum freeze dryer, fill it to 12cm-15cm, move it into the freeze-drying chamber of the vacuum freeze dryer, close the door, and slowly cool down to -30°C - -40°C, it takes 2-6 hours, -40°C for 3 hours → evacuate to a vacuum of 20-30Pa → heat the board to 110°C - 100°C for 6-10 hours, the material temperature is -34°C - -38°C, carry out sublimation drying → reduce the layer temperature to 105°C - 90°C, mai...

Embodiment 1

[0020] A preparation method of Lycium barbarum leaf freeze-dried powder, characterized in that said method comprises the following steps: 1) Preparation step of Lycium barbarum leaf concentrate

[0021] Fresh goji berry leaves→Wash once with water→Blanching for 20 seconds→Squeeze the juice slowly→Collect the concentrated goji berry leaf juice→Store in a -20°C freezer for later use;

[0022] 2) Freeze sublimation step Thaw the concentrated wolfberry leaf juice, mix it and move it into the loading tray of the vacuum freeze dryer, fill it to 12cm, move it into the freeze-drying chamber of the vacuum freeze dryer, close the door, and slowly cool down to -30°C. 2 hours, -40°C for 3 hours→vacuumize to a vacuum of 20Pa→heat the board to 110°C for 6 hours, material temperature at -34°C, carry out sublimation drying→reduce the temperature of the board to 105°C, maintain for 4 hour, the temperature of the material is -30°C → continue to reduce the temperature of the plate layer to 100°C...

Embodiment 2

[0027] A preparation method of Lycium barbarum leaf freeze-dried powder, characterized in that said method comprises the following steps: 1) Preparation step of Lycium barbarum leaf concentrate

[0028] Fresh wolfberry leaves→Wash twice with water→Blanching for 35 seconds→Squeeze the juice at a slow speed→Collect the concentrated juice of wolfberry leaves→Store in a -30°C freezer for later use;

[0029] 2) Freeze sublimation step Thaw the concentrated wolfberry leaf juice, mix it and move it into the loading tray of the vacuum freeze dryer, fill it to 13.5cm, move it into the freeze-drying chamber of the vacuum freeze dryer, close the door, and slowly cool down to -35°C. It takes 4 hours, maintain at -40°C for 3 hours → evacuate to a vacuum of 25Pa → heat the layer to 105°C and maintain for 8 hours, the temperature of the material is at -36°C, carry out sublimation drying → reduce the temperature of the layer to 100°C, and maintain After 5 hours, the temperature of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com