Nutrition healthcare peony nutritious food based on infrared spouted bed drying and making method

A technology of spouted bed and nutritious meal, which is applied in the field of food processing, can solve the problems of not being able to match delicious food and nutrition, achieve the effects of increasing polysaccharide content and soluble dietary fiber extraction rate, fast drying speed, and ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

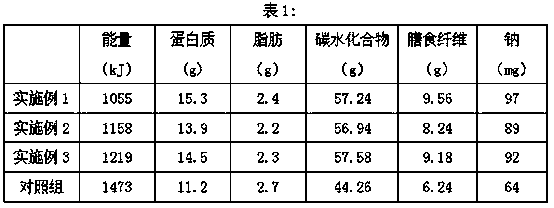

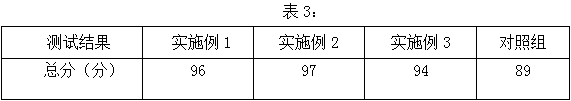

Embodiment 1

[0025] A high-fiber peony nutritious meal based on infrared spouted bed drying, the nutritious meal is made of the following raw materials in parts by weight: 25 parts of peony, 10 parts of rose, 5 parts of barley, 7 parts of sweet potato, 5 parts of wheat, 3 parts of dandelion, 3 parts of lotus leaf, 5 parts of red dates, 10 parts of sugar.

[0026] The preparation method comprises the following steps:

[0027] Step 1), weighing each raw material according to the above parts by weight;

[0028] Step 2), mix and steam the barley, sweet potato and wheat weighed in step 1) for 30-50 minutes and grind the dandelion, lotus leaves and red dates weighed in step 1) with ultrafine powder technology, and pass through a 200-mesh sieve after crushing, Obtain superfine powder mixed fine powder;

[0029] Step 3): Wash the peonies and roses weighed in step 1) and remove the petals, remove the receptacles and other foreign objects, petals that are rotten and pests, rinse them with clean wa...

Embodiment 2

[0033] A high-fiber peony nutritious meal based on infrared spouted bed drying, the nutritious meal is made of the following raw materials in parts by weight: 30 parts of peony, 13 parts of rose, 7 parts of barley, 8 parts of sweet potato, 7 parts of wheat, 4 parts of dandelion, 4 parts of lotus leaf, 7 parts of red dates, 12 parts of sugar.

[0034] The preparation method comprises the following steps:

[0035] Step 1), weighing each raw material according to the above parts by weight;

[0036] Step 2), mix and steam the barley, sweet potato and wheat weighed in step 1) for 30-50 minutes and grind the dandelion, lotus leaves and red dates weighed in step 1) with ultrafine powder technology, and pass through a 200-mesh sieve after crushing, Obtain superfine powder mixed fine powder;

[0037] Step 3): Wash the peonies and roses weighed in step 1) and remove the petals, remove the receptacles and other foreign objects, petals that are rotten and pests, rinse them with clean wa...

Embodiment 3

[0041] A high-fiber peony nutritious meal based on infrared spouted bed drying, the nutritious meal is made of the following raw materials in parts by weight: 35 parts of peony, 15 parts of rose, 10 parts of barley, 10 parts of sweet potato, 10 parts of wheat, 5 parts of dandelion, 5 parts of lotus leaf, 8 parts of red dates, 15 parts of sugar.

[0042] The preparation method comprises the following steps:

[0043] Step 1), weighing each raw material according to the above parts by weight;

[0044] Step 2), mix and steam the barley, sweet potato and wheat weighed in step 1) for 30-50 minutes and grind the dandelion, lotus leaves and red dates weighed in step 1) with ultrafine powder technology, and pass through a 200-mesh sieve after crushing, Obtain superfine powder mixed fine powder;

[0045] Step 3): Wash the peonies and roses weighed in step 1) and remove the petals, remove the receptacles and other foreign objects, petals that are rotten and pests, rinse them with clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com