Energy-saving type composite phase-change energy storage material processing device capable of using solar heat source

A composite phase change and material processing technology, applied in solar thermal devices, solar thermal energy, solar collectors using working fluids, etc., can solve problems such as low production efficiency, waste of materials, and high labor intensity, and achieve high production efficiency , High heat collection efficiency, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

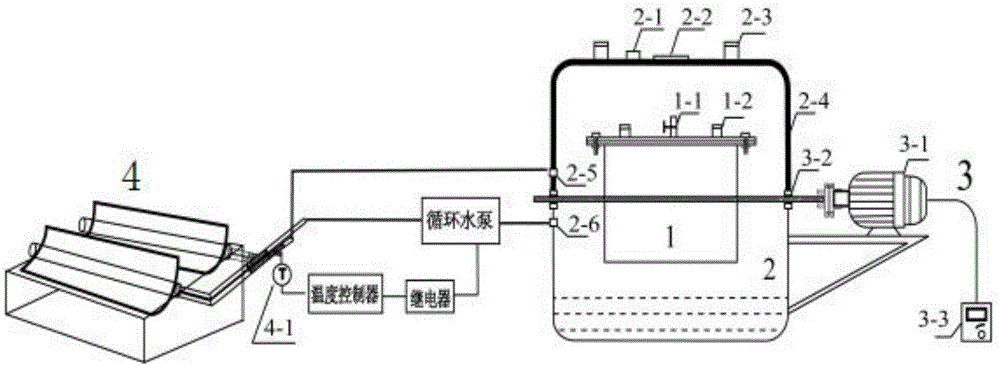

[0037] This embodiment can utilize the energy-saving composite phase-change energy-storage material processing device of solar heat source (abbreviation device, see Figure 1-2 ), including a drum device body 1, a heating barrel 2, a power unit 3 and a trough solar collector 4, the drum device body 1 is fixed in the heating drum 2, and the drum device body 1 is driven in the heating barrel by the power unit 3 Rotate, the trough solar collector 4 is connected with the heating barrel 2;

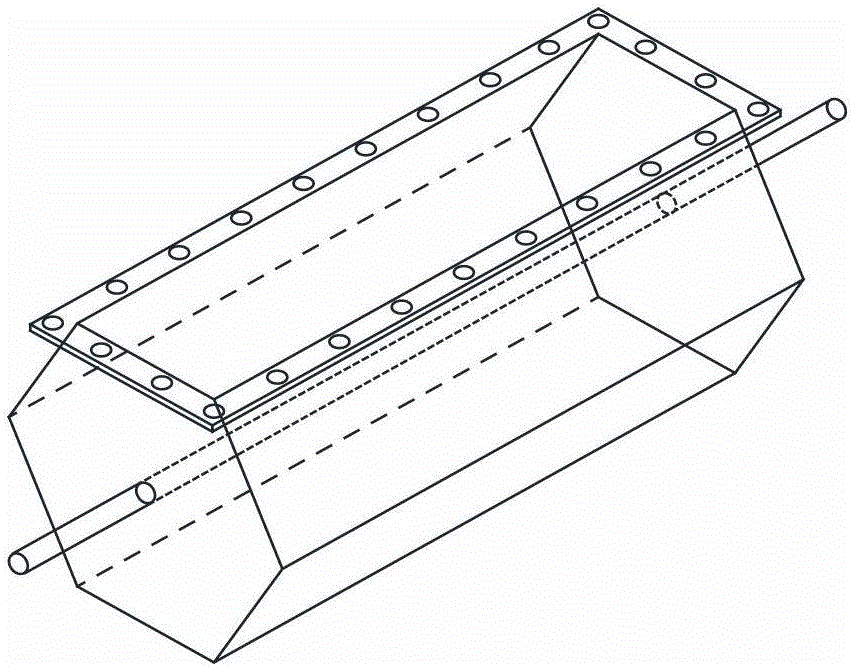

[0038] The drum device body 1 is a hexagonal prism, and the installation method is horizontal. When rotating, it can ensure that the phase change material and the porous material are fully contacted and mixed, and all of them participate in the adsorption reaction. One side of the drum device body 1 is a detachable flange. Type, the side is connected with an end cover through a sealing screw, and an inner cover removal handle 1-2 and a vacuum pumping hole 1-1 are arranged on the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com