Beneficiation method for recovery of fluorite in white tungsten heating cleaner tailings

A beneficiation method and tailings technology, applied in flotation, solid separation and other directions, can solve the problems of difficult fluorite, poor effect, difficult separation of calcite and fluorite, etc., to avoid wasteful loss, good economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

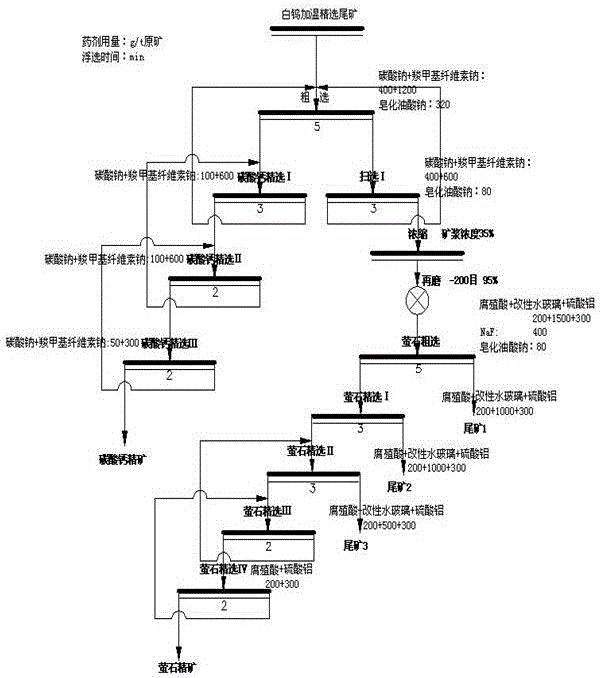

[0018] combined with figure 1 The above-described mineral processing method for recovering fluorite from scheelite heating and concentrating tailings, heating and concentrating tailings, adding 400 g / t of regulator sodium carbonate and 1200 g of inhibitor sodium carboxymethyl cellulose by weight / t, the collector saponified sodium oleate 320 g / t, and conduct roughing; roughing tailings are added with regulator sodium carbonate 400 g / t, inhibitor carboxymethyl cellulose sodium 600 g / t, collector saponified Sodium oleate 80 g / t, for sweeping; the rougher concentrate enters the beneficiation, adding the regulator sodium carbonate 100g / t, the inhibitor carboxymethyl cellulose sodium 600 g / t, once beneficiating; adding the regulator carbonic acid Sodium 100g / t, inhibitor carboxymethyl cellulose sodium 600g / t, second selection; add regulator sodium carbonate 50 g / t, inhibitor carboxymethyl cellulose sodium 300 g / t, third selection; The beneficiation tailings are returned in turn to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com