A kind of titanium oxide photocatalyst and preparation method thereof

A technology of photocatalyst and titanium oxide, which is applied in the field of photocatalysis, can solve the problems of limited application and unsatisfactory photocatalytic effect, and achieve the effect of improving catalytic effect, simple and easy synthesis process, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

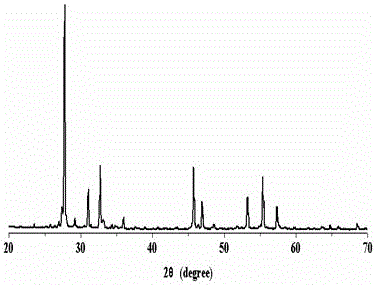

Embodiment 1

[0020] Add 4.0g of divinylbenzene monomer to a mixed solvent of 15g of acetone, methanol and dimethylformamide (the volume ratio of the three is 50:20:30), add 0.05g of 2,2-azobisnitrile pentyl Acid initiator (1% of the mass of divinylbenzene), then add 1.4g of titanium tetrachloride, stir at room temperature for 60min, put it into a hydrothermal synthesis reactor; polymerize at 180°C for 24h, and obtain a massive composite solid. Open the hydrothermal synthesis reaction kettle, add 0.0015mol / L sulfuric acid solution, the volume added is twice the volume of the mixed solvent of acetone, methanol and dimethylformamide, hydrothermal treatment at 240°C for 36h, after the reaction stops, take out the solid sample, put Put into vacuum heating (80 ℃) dry 10h, remove the organic solvent, can obtain blocky polymer material, wherein the mass fraction of titanium dioxide is 13%, its measured specific surface area is 423 m 2 / g, the pore size is about 35 nanometers, and the XRD test show...

Embodiment 2

[0022] Prepared according to the method in Embodiment 1, only changing the ratio of the solvents acetone, methanol and dimethylformamide (the volume ratio of the three is 45:35:20); a blocky polymer material can be obtained, wherein the mass fraction of titanium dioxide is 13 %, the measured specific surface area is 355 m 2 / g, the pore diameter is about 21 nanometers, and the XRD test shows that the ratio of the two crystal forms of rutile and anatase is about 2:3. According to embodiment 1, put the sample in 50 mg / L rhodamine B solution, and after irradiating for 2 hours under a 500W xenon lamp, the COD value of the rhodamine B solution is 18 mg / L.

Embodiment 3

[0024] Prepared according to the method in Embodiment 1, only changing the ratio of the solvents acetone, methanol and dimethylformamide (the volume ratio of the three is 40:35:25); a blocky polymer material can be obtained, in which the mass fraction of titanium dioxide is 13 %, the measured specific surface area is 449 m 2 / g, the pore diameter is about 21 nanometers, and the XRD test shows that the ratio of the two crystal forms of rutile and anatase is about 1:3. Take 50mg of the sample, put it into 2ml of 50mg / L Rhodamine B solution, and irradiate it under a 500W xenon lamp for 2h, the COD value of Rhodamine B solution will drop to 5 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com