Continuous ethanol recovery and salicylic acid removal process for carbaspirin calcium mother liquor

A technology of carbasalate calcium and salicylic acid, which is applied in the fields of organic chemistry, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems not involving the recycling of carbasalate calcium mother liquor, and achieve good properties, low energy consumption, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

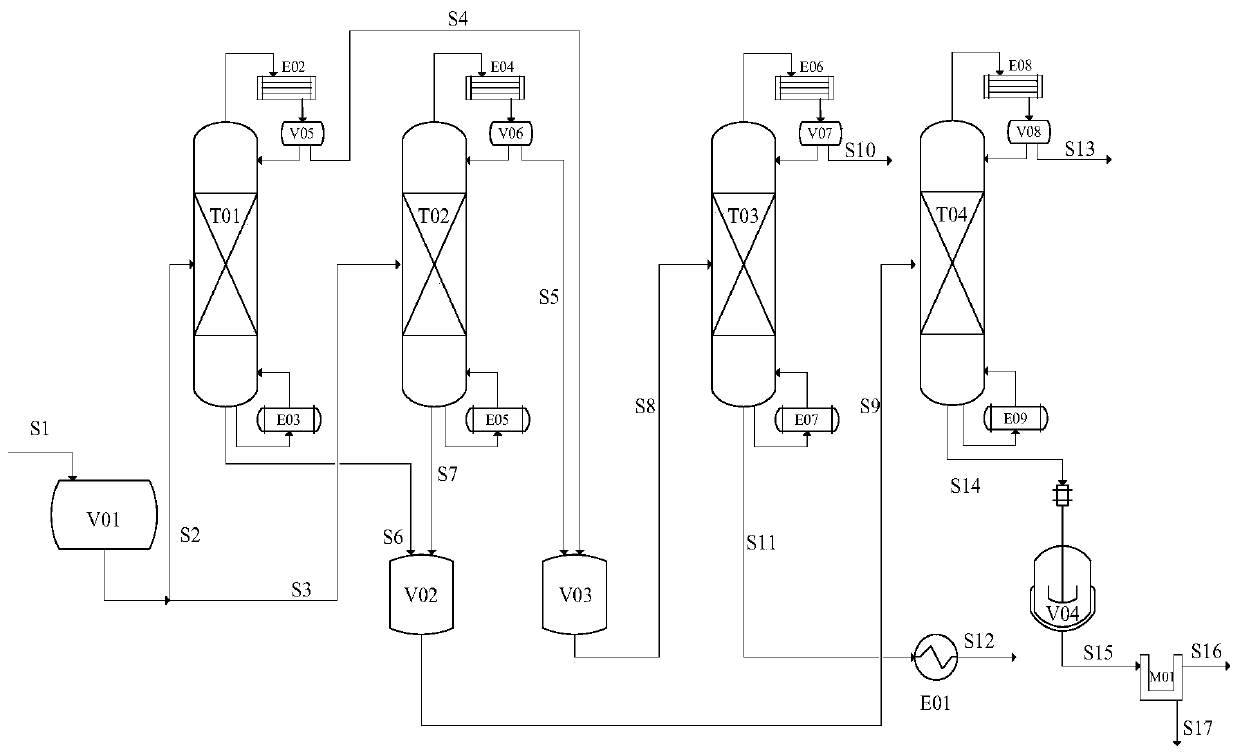

Embodiment 1

[0033]Distillation tower (T01) and rectification tower (T02) feed flow rate is 785kg / h, and feed temperature is 30 ℃, and contains ethanol 72.5%, water 18.8%, salicylic acid 1.7%, ammonium nitrate 7% in the feed % (mass fraction), the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 40, the raw material feed plate is 30, the reflux ratio is 4.5, and the output at the top of the tower is 579kg / h, and the rectifying tower (T03) enters The material flow rate is 1158kg / h, the feed temperature is 78°C, the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 20, the raw material feeding plate is 3, the reflux ratio is 2.9, and the output at the top of the tower is 61.5kg / h, the rectifying tower (T04) feed flow rate is 412kg / h, and feed temperature is 93 ℃, and operating pressure is 1atm (absolute pressure), and theoretical plate number is 20, and raw material feed plate is 8, and reflux ratio is 1.5, The output at t...

Embodiment 2

[0035] The rectification tower (T01) and the rectification tower (T02) feed flow rate are 1100kg / h, and the feed temperature is 32 ℃, and the feed contains ethanol 72.5%, water 18.8%, salicylic acid 1.7%, ammonium nitrate 7% % (mass fraction), the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 45, the raw material feed plate is 30, the reflux ratio is 4.3, and the output at the top of the tower is 811kg / h, and the rectifying tower (T03) enters The material flow rate is 1622kg / h, the feed temperature is 78°C, the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 25, the raw material feeding plate is 3, the reflux ratio is 2.5, and the output at the top of the tower is 86kg / h , the rectification column (T04) feed flow rate is 578kg / h, the feed temperature is 93°C, the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 20, the raw material feed plate is 8, and the reflux ratio i...

Embodiment 3

[0037] Distillation tower (T01) and rectification tower (T02) feed flow rate is 650kg / h, and feed temperature is 40 ℃, and contains ethanol 72.5%, water 18.8%, salicylic acid 1.7%, ammonium nitrate 7% in the feed % (mass fraction), the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 50, the raw material feed plate is 30, the reflux ratio is 4, and the output at the top of the tower is 479kg / h, and the rectifying tower (T03) enters The material flow rate is 958kg / h, the feed temperature is 78°C, the operating pressure is 1atm (absolute pressure), the number of theoretical plates is 20, the raw material feeding plate is 4, the reflux ratio is 3.2, and the output at the top of the tower is 51kg / h , the rectification tower (T04) feed flow rate is 342kg / h, and feed temperature is 93 ℃, and operating pressure is 1atm (absolute pressure), and theoretical plate number is 25, and raw material feed plate is 18, and reflux ratio is 3, and column The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com