Preparation method of titanium and aluminium dissimilar metal thick plate overlapping structure

A technology of dissimilar metals and joining structures, applied in metal processing equipment, welding equipment, metal processing and other directions, can solve the problems of cracking and welding of cladding, difficult dissimilar metal structures, difficulties, etc., to achieve reliable structural quality, avoid direct contact, Simple and controllable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

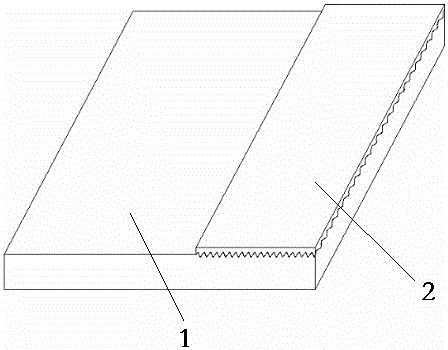

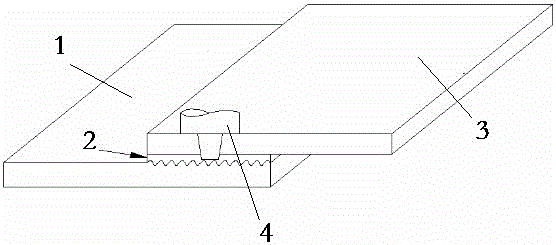

[0024] Such as Figure 1-2 As shown, the present invention provides a kind of preparation method of titanium and aluminum dissimilar metal plate overlapping structure, comprises the following steps:

[0025] (1) Explosive welding is used to connect the titanium alloy substrate 1 and the thin aluminum alloy cladding plate 2 to obtain a composite plate, and the thickness of the thin aluminum alloy cladding plate is 1.5-3mm;

[0026] (2) Friction stir welding is used to connect the composite plate obtained in the step (1) and the thick aluminum alloy cladding plate 3 to obtain a lap joint structure of titanium and aluminum dissimilar metal plates; number 4 is a stirring head.

[0027] The thick aluminum alloy plate is in contact with the thin aluminum alloy cladding layer in the composite plate.

[0028] The invention adopts friction stir welding to connect the clad plate obtained in the step (1) and the thick aluminum alloy plate to obtain a step-by-step connection method of th...

Embodiment 1

[0051] 1. Pretreatment before explosive welding: Grinding the TC4 titanium alloy substrate with a thickness of 20mm and the 2A12 thin aluminum alloy cladding with a thickness of 2mm by grinding with a wire brush to remove the titanium alloy substrate and aluminum Oxide film on the surface of the alloy cladding plate; then use sandpaper to polish the surface after grinding to make the surface clean and smooth, and ensure that the surface roughness is Ra1.25-2.5μm; then clean the surface with absolute ethanol to ensure that the surface is clean.

[0052] 2. Explosive welding: place the processed titanium alloy substrate on a soft and flat sandy soil foundation, and place the processed thin aluminum alloy cladding plate on top of the titanium alloy with the surface to be welded facing up; the prefabricated explosive frame Put it on the aluminum alloy in parallel; install and fix the discharge detonator at the corner of the explosive frame; use the electric detonator detonator to d...

Embodiment 2

[0058] 1. Pretreatment before explosive welding: use wire brush to grind the TC4 titanium alloy substrate side with a thickness of 30mm and the 2A12 thin aluminum alloy cladding plate side with a thickness of 2mm to fully grind to remove the titanium alloy substrate and aluminum alloy. Oxide film on the surface of the alloy cladding plate; then use sandpaper to polish the surface after grinding to make the surface clean and smooth, and ensure that the surface roughness is Ra1.25-2.5μm; then clean the surface with absolute ethanol to ensure that the surface is clean.

[0059] 2. Explosive welding: place the processed titanium alloy substrate on a soft and flat sandy soil foundation, and place the processed thin aluminum alloy cladding plate on top of the titanium alloy with the surface to be welded facing up; the prefabricated explosive frame Put it on the aluminum alloy in parallel; install and fix the discharge detonator at the corner of the explosive frame; use the electric d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com