Piston metal machining device

A metal processing and piston technology, applied in the field of piston metal processing devices, can solve the problems of easy dripping of lubricating oil on the staff, difficult control of oiling uniformity, low work efficiency, etc. Accurate and improve the effect of clamping fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to further describe the present invention, it is further described below in conjunction with embodiment.

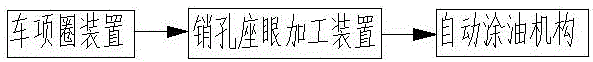

[0055] Such as figure 1 As shown, the invention discloses a piston metal processing device, which includes a car collar device, a pin hole seat hole processing device, and an automatic oiling mechanism in sequence from the front to the rear according to the technological process.

[0056] The car collar device includes a semi-automatic hydraulic machine tool body and a car collar tool assembly. The present invention preferably adopts C7620 / 1A semi-automatic hydraulic machine tool, of course, other prior art machine tools can also be used.

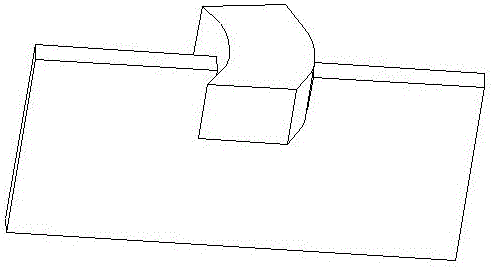

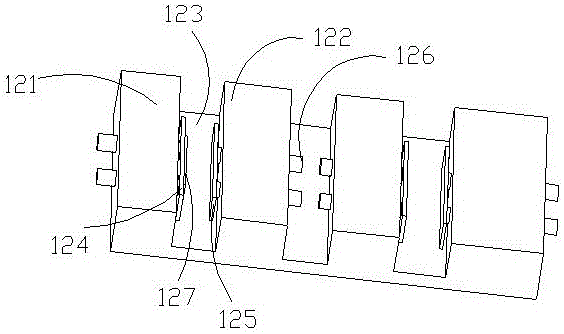

[0057] Such as image 3 , 4 , 5, and 6, the car collar clamping tool assembly disclosed in this embodiment includes a tool and a clamp. The fixture is used to hold the tool. The knife includes a handle portion 111 and a blade portion 112 . The handle portion 111 and the blade portion 112 are integrally formed. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com