A method for preparing large and round ε-hniw crystals with different concentrations

A technology of large particles and crystals, which is applied in the field of preparing large particles and smooth ε-HNIW crystals, which can solve the problems of poor morphology and achieve the effects of smooth crystals, easy industrialization, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

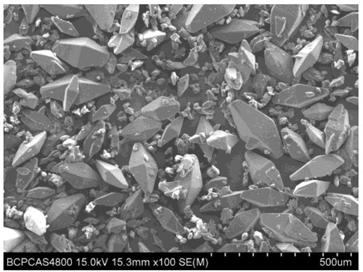

Embodiment 1

[0025] Dissolve 7g of HNIW in 20mL of industrial ethyl acetate, filter the solution for use as filtrate A, dissolve 40g of HNIW in 100mL of industrial ethyl acetate, filter the solution for use as filtrate B; first wash the crystallization kettle with industrial ethyl acetate, and then use industrial Rinse with n-octane, then add 50ml of industrial n-octane to the crystallization kettle, place the crystallization kettle in a constant temperature water bath at 40°C; turn on the agitator, preheat and keep warm at a low speed of 100rpm until the temperature of the anti-solvent is the same as the water temperature in the jacket; Then the stirring speed is adjusted to 350rpm, and the constant flow pump is started to drip the filtrate A in the crystallization tank at a rate of 40mL / min; after all the addition is completed, continue to stir for 35min; Add the filtrate B dropwise to the crystallization kettle with the constant flow pump, stir for 2 minutes after all the addition is com...

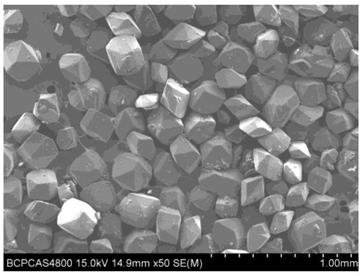

Embodiment 2

[0028] Dissolve 12g of HNIW in 40mL of industrial ethyl acetate, filter the solution for use as filtrate A, dissolve 80g of HNIW in 200mL of industrial ethyl acetate, filter the solution for use as filtrate B; first wash the crystallization kettle with industrial ethyl acetate, and then use industrial Rinse with n-octane, then add 120ml of industrial n-octane to the crystallization kettle, place the crystallization kettle in a 40°C constant temperature water bath; turn on the stirrer, preheat and keep warm at a low speed of 100rpm until the temperature of the anti-solvent is the same as the water temperature in the jacket, Then the stirrer speed was adjusted to 350rpm, and the constant flow pump was turned on to drip the filtrate A into the crystallization tank at a rate of 50mL / min; Add the filtrate B dropwise to the crystallization kettle with the pump, and stir for 2 minutes after all the addition is completed, then turn on the constant flow pump and add 400ml of n-octane dr...

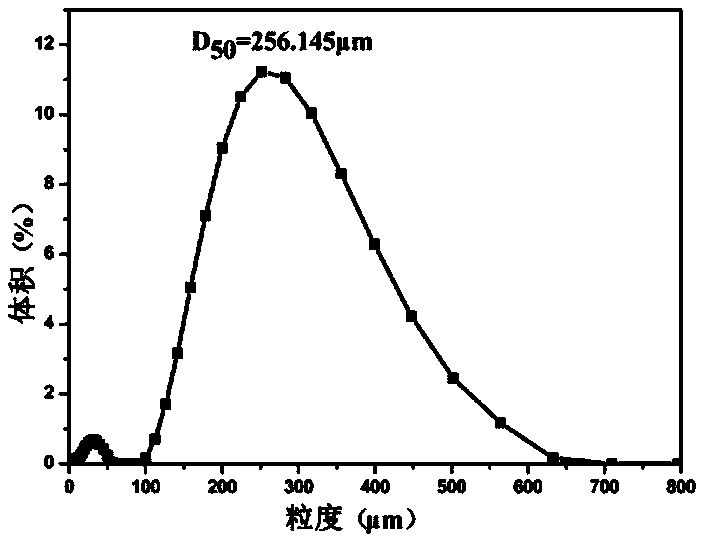

Embodiment 3

[0031] Dissolve 160g of HNIW in 500mL of industrial ethyl acetate, filter the solution for use as filtrate A, dissolve 1kg of HNIW in 2.5L of industrial ethyl acetate, filter the solution for use as filtrate B; wash the crystallization kettle with industrial ethyl acetate first, and then use Rinse with industrial n-octane, then add 1.5L industrial n-octane to the crystallization kettle, place the crystallization kettle in a constant temperature water bath at 38°C; turn on the stirrer, preheat and keep warm at a low speed of 100rpm until the temperature of the anti-solvent is the same as the water temperature in the jacket The same, then adjust the stirrer speed to 300rpm, turn on the constant flow pump to drip the filtrate A into the crystallization tank at a rate of 35mL / min; Add the filtrate B dropwise to the crystallization kettle with the constant flow pump, stir for 5 minutes after all the addition is completed, then turn on the constant flow pump and add 6L n-octane dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com