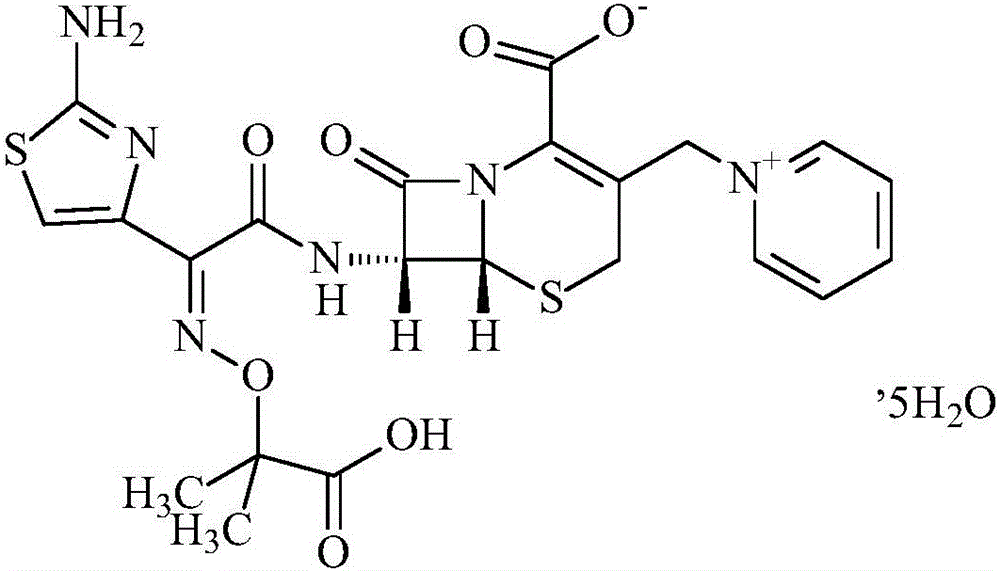

Ceftazidime compound prepared by adopting coupling crystallization technology and preparation thereof

A technology of ceftazidime and compound, applied in the field of ceftazidime compound and preparation thereof, can solve problems such as poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

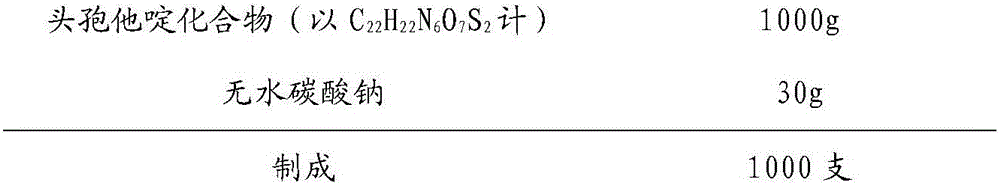

[0028] Embodiment 1: the preparation of ceftazidime compound

[0029] (1) Add 0.547kg of ceftazidime crude product into 5kg of purified water, add 0.09kg of sodium ethylate, stir and dissolve, let stand, and react for 4 hours;

[0030] (2) Add 5kg of isopropanol, stir, lower the temperature to -10°C, let stand for 10 hours, precipitate crystals, filter, wash with ethanol to obtain a filter cake, and dry to obtain 0.592kg of compound;

[0031] (3) Put the above compound in 2kg of purified water, stir and dissolve, add dropwise 2mol / L hydrochloric acid solution, adjust the pH value to 3.53, lower the temperature to 5°C, let it stand for 10 hours, precipitate crystals, filter, and wash with cold water to obtain The filter cake was dried to obtain 0.497 kg of ceftazidime with a yield of 91%.

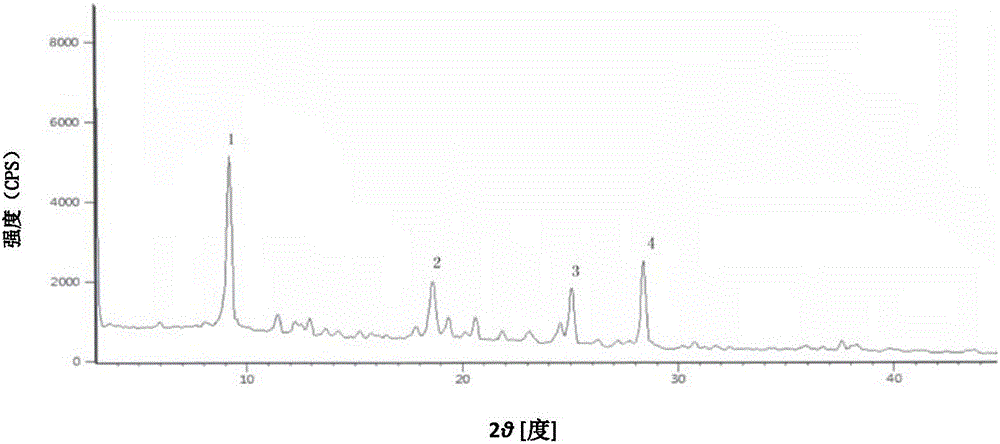

[0032] Crystal form determination results: the X-ray powder diffraction pattern of ceftazidime in Example 1 shows characteristic diffraction peaks at 9.24°, 18.64°, 25.10°, and 28.42°.

[...

Embodiment 2

[0036] Embodiment 2: the preparation of ceftazidime compound

[0037] (1) Add 1.13kg of ceftazidime crude product into 10kg of purified water, add 0.11kg of sodium carbonate, stir and dissolve, leave standstill, and react for 4 hours;

[0038] (2) Add 15kg of ethanol, stir, lower the temperature to -5°C, let stand for 10 hours, precipitate crystals, filter, wash with ethanol to obtain a filter cake, and dry to obtain 1.22kg of compound;

[0039] (3) Put the above compound in 5 kg of purified water, stir and dissolve, add dropwise 2mol / L nitric acid solution, adjust the pH value to 3.47, lower the temperature to 2°C, let it stand for 10 hours, precipitate crystals, filter, and wash with cold water to obtain The filter cake was dried to obtain 1.02 kg of ceftazidime with a yield of 90%.

Embodiment 3

[0040] Embodiment 3: the preparation of ceftazidime compound

[0041] (1) Add 3.32kg of ceftazime crude product into 20kg of purified water, add 0.4kg of sodium hydroxide, stir and dissolve, leave standstill, and react for 4 hours;

[0042] (2) Add 25kg of ethanol, stir, lower the temperature to 0°C, let stand for 10 hours, precipitate crystals, filter, wash with ethanol to obtain a filter cake, and dry to obtain 3.65kg of compound;

[0043] (3) Put the above compound in 10kg of purified water, stir and dissolve, add dropwise 2mol / L acetic acid solution, adjust the pH value to 3.49, lower the temperature to 0°C, let it stand for 10 hours, precipitate crystals, filter, and wash with cold water to obtain The filter cake was dried to obtain 3.06 kg of ceftazidime with a yield of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com