Polytetrafluoroethylene composite, polytetrafluoroethylene composite holder for bearing and preparation method of polytetrafluoroethylene composite holder for bearing

A technology of polytetrafluoroethylene and composite materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems that cannot meet the requirements of dn value bearing working conditions, achieve excellent self-lubricating performance, enhance friction and wear performance, Effects of improving thermal conductivity and friction and wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

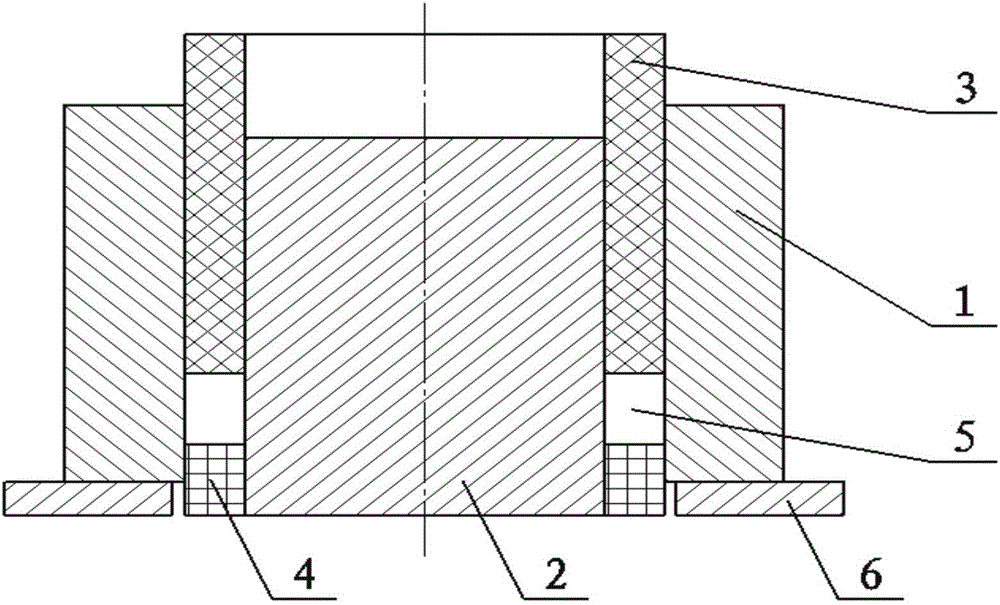

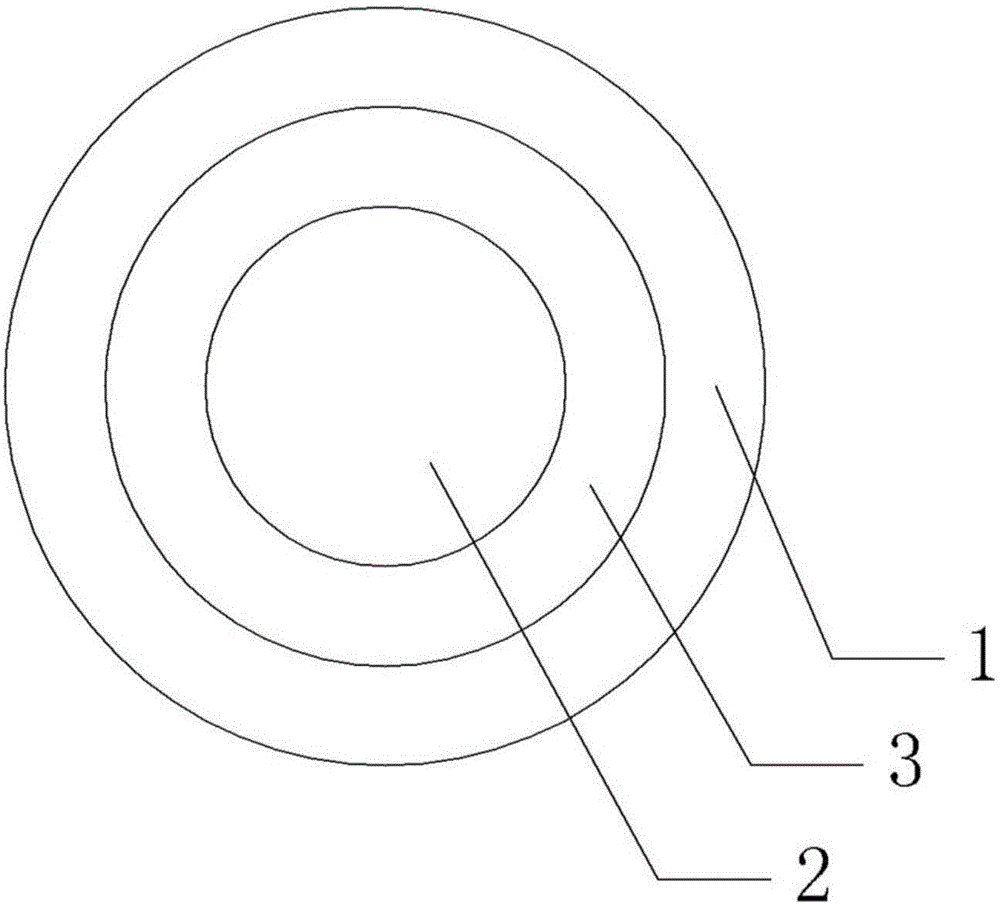

Image

Examples

Embodiment 1

[0047] The polytetrafluoroethylene composite material of this embodiment is composed of the following components in mass percentage: 3% of KH-570 modified nano-alumina, 5% of molybdenum disulfide, and 92% of polytetrafluoroethylene.

[0048] The polytetrafluoroethylene composite cage for bearings in this embodiment is composed of the following components in mass percentage: KH-570 modified nanometer aluminum oxide 3%, molybdenum disulfide 5%, polytetrafluoroethylene 92%.

[0049] The preparation method of the polytetrafluoroethylene composite cage for the bearing of the present embodiment comprises the following steps:

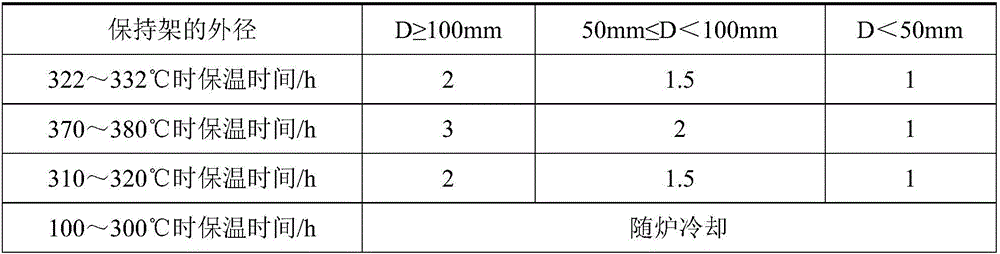

[0050] 1) Nano-alumina is placed in the container of the absolute ethanol solution of silane coupling agent KH-570 with a mass concentration of 2%, the container is placed in an ultrasonic tank, and the nano-alumina is coupled Coupling and ultrasonic dispersion, the ultrasonic frequency is 18KHz, and the ultrasonic time is 30 minutes; the above-mentioned coupl...

Embodiment 2

[0058] The polytetrafluoroethylene composite material of this embodiment is composed of the following components in mass percentage: 5% KH-570 modified nano-alumina, 4% molybdenum disulfide, and 91% polytetrafluoroethylene.

[0059] The polytetrafluoroethylene composite cage for bearings in this embodiment is composed of the following components in mass percentage: 5% KH-570 modified nano-alumina, 4% molybdenum disulfide, and 91% polytetrafluoroethylene.

[0060] The preparation method of the polytetrafluoroethylene composite cage for the bearing of the present embodiment comprises the following steps:

[0061] 1) Nano-alumina is placed in the container of the absolute ethanol solution of silane coupling agent KH-570 with a mass concentration of 2%, the container is placed in an ultrasonic tank, and the nano-alumina is coupled Coupling and ultrasonic dispersion, the ultrasonic frequency is 18KHz, and the ultrasonic time is 28 minutes; the above-mentioned coupled and ultrasonic...

Embodiment 3

[0069] The polytetrafluoroethylene composite material of this embodiment is composed of the following components in mass percentage: 8% KH-570 modified nano-alumina, 2% molybdenum disulfide, and 90% polytetrafluoroethylene.

[0070] The polytetrafluoroethylene composite cage for bearings in this embodiment is composed of the following components in mass percentage: 8% KH-570 modified nano-alumina, 2% molybdenum disulfide, and 90% polytetrafluoroethylene.

[0071] The preparation method of the polytetrafluoroethylene composite cage for the bearing of the present embodiment comprises the following steps:

[0072] 1) Nano-alumina is placed in the container of the absolute ethanol solution of silane coupling agent KH-570 with a mass concentration of 2%, the container is placed in an ultrasonic tank, and the nano-alumina is coupled Coupling and ultrasonic dispersion, the ultrasonic frequency is 22KHz, and the ultrasonic time is 20 minutes; the above-mentioned coupled and ultrasonical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com