Method for immobilizing proteins in natural rubber latex by aid of modified tannin extract

A technology of natural rubber latex and protein, which is applied in the field of fixing natural rubber latex protein by using modified tannin extract, which can solve the adverse effects of raw rubber drying rate and oxidation resistance on the mechanical properties of rubber products, and it is difficult to realize on-site preparation and use, latex Colloidal system stability decline and other problems, to achieve the effect of feasible process, easy control, mild reaction conditions and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

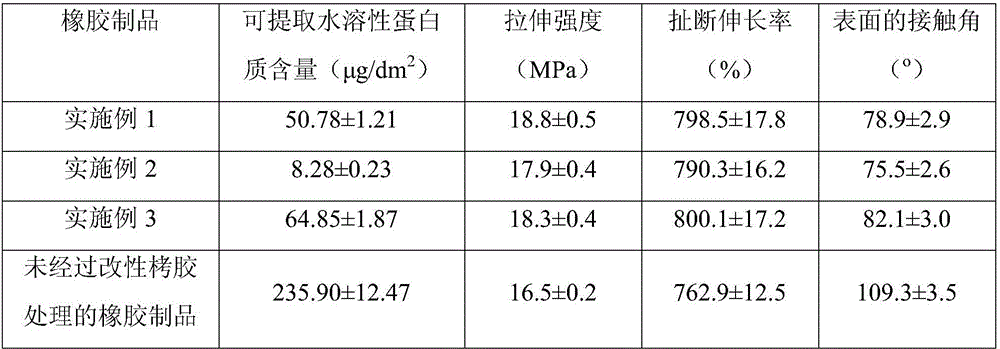

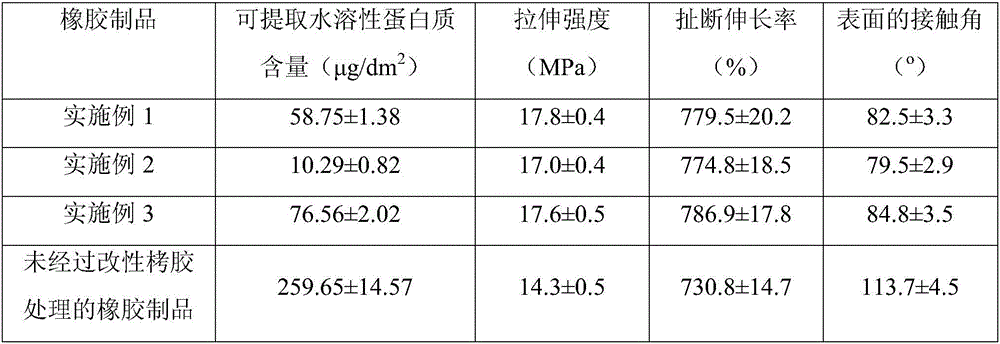

Embodiment 1

[0020] In 1 weight part of the mass percentage content of 10% ammonia solution, under the stirring condition of 60 rpm, add 1 weight part of the mass percentage content of 20% sodium sulfite aqueous solution, add 15 weight parts of the mass percentage content of A 20% aqueous solution of commercially available powdered Acacia quinquefolium extract was stirred for 15 minutes, and then reacted at 60° C. for 1 hour to obtain a modified Acacia quinquefolium solution. The modified Acacia manzhani solution was left at room temperature for 90 minutes, then centrifuged at 8000 rpm for 15 minutes, and the supernatant was collected to obtain the purified modified Acacia manzanzi solution. Under room temperature conditions, according to the ratio of adding 1 weight part of solid modified acacia acacia in the natural rubber latex of every 100 parts by weight, the modified acacia acacia solution of purification is added in the high-ammonia concentrated natural rubber latex, and stirred to m...

Embodiment 2

[0022]In 1 weight part of the mass percentage content of 25% ammonia solution, under the stirring condition of 30 rev / min, add 3 weight parts of the mass percentage content of 30% hydrogen peroxide solution, add 20 weight parts of the mass percentage The aqueous solution of commercially available powdered oak extract with a content of 20% was stirred for 30 minutes, and then reacted at 30°C for 1 hour to obtain a modified rubber extract solution. The modified rubber bowl solution was left at room temperature for 60 minutes, then centrifuged at 6000 rpm for 30 minutes, and the supernatant was collected to obtain a purified modified rubber bowl solution. At room temperature, according to the ratio of adding 0.2 parts by weight of solid modified rubber latex in every 100 parts by weight of natural rubber latex, the modified rubber bowl solution of increasing purity is added in high-ammonia concentrated natural rubber latex, and stirred to make the modification The rubber bowl is ...

Embodiment 3

[0024] In 1 weight part of the mass percentage content of 15% ammonia solution, under the stirring condition of 45 rpm, add 1 weight part of the mass percentage content of 20% potassium sulfite aqueous solution and 1 weight part of the mass percentage content To a 20% hydrogen peroxide solution, add 25 parts by weight of an aqueous solution of commercially available powdered bayberry extract with a mass percentage of 30%, stir for 30 minutes, and then react at 50° C. for 1 hour to obtain a modified bayberry solution. The modified bayberry solution was left at room temperature for 30 minutes, then centrifuged at 8000 rpm for 30 minutes, and the supernatant was collected to obtain a purified modified bayberry solution. Under room temperature conditions, according to the ratio of adding 2 parts by weight of solid modified red bayberry in the natural rubber latex of every 100 parts by weight, the modified red bayberry solution of increasing purity is added in the high-ammonia conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com