A method for directional enrichment and extraction of uranium during coal combustion

A directional enrichment and coal combustion technology, applied in the direction of improving process efficiency, can solve the problems of huge consumption of extraction reagents, difficult extraction process, and lower uranium extraction rate, and achieve efficient directional enrichment, simple operation, and reduction of uranium. the drain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The embodiment of the present invention is a method for directional enrichment and extraction of uranium in the coal combustion process, which is carried out by the above-mentioned device. The specific steps of the method are as follows:

[0039] (1) Using step-by-step chemical extraction method and inductively coupled plasma mass spectrometry (ICP-MS) to test the content of organically bound uranium in coal m 1 = 6mg / kg coal;

[0040] (2) According to the content m of the organically bound uranium in the step (1) 1 , determine the amount of CaO added as m 2 =k 1 m 1 , where k 1 =1.1, that is, 6.6mg CaO is added per kg of coal;

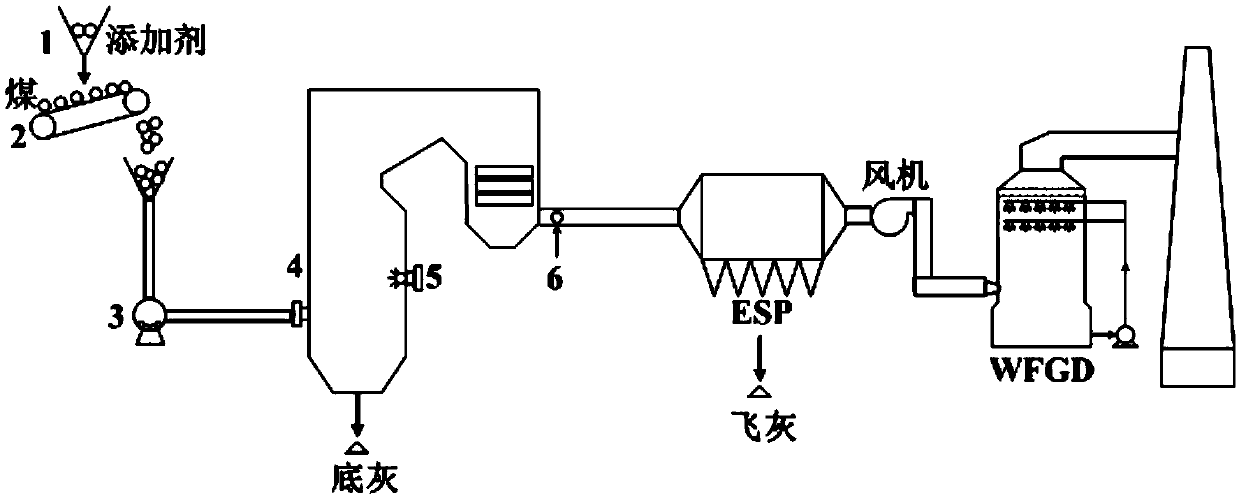

[0041] (3) by attaching figure 1 In the additive addition system, the additive CaO is added to the coal conveying system. The additive and coal are fully mixed in the coal mill and then enter the boiler furnace for combustion. The additive reacts with gaseous uranium in the furnace to form solid CaUO. 4 , these solid-state CaUO 4 It wil...

Embodiment 2

[0046] The embodiment of the present invention is a method for directional enrichment and extraction of uranium in the coal combustion process, which is carried out by the above-mentioned device. The specific steps of the method are as follows:

[0047] (1) Using step-by-step chemical extraction method and inductively coupled plasma mass spectrometry (ICP-MS) to test the content of organically bound uranium in coal m 1 = 6.9 mg / kg coal;

[0048] (2) According to the content m of the organically bound uranium in the step (1) 1 , determine the amount of CaO added as m 2 =k 1 m 1 , where k 1 =1.3, that is, 8.97mg CaO is added per kg of coal;

[0049] (3) by attaching figure 1 In the additive addition system, the additive CaO is added to the coal conveying system. The additive and coal are fully mixed in the coal mill and then enter the boiler furnace for combustion. The additive reacts with gaseous uranium in the furnace to form solid CaUO. 4 , these solid-state CaUO 4 It...

Embodiment 3

[0054] The embodiment of the present invention is a method for directional enrichment and extraction of uranium in the coal combustion process, which is carried out by the above-mentioned device. The specific steps of the method are as follows:

[0055] (1) Using step-by-step chemical extraction method and inductively coupled plasma mass spectrometry (ICP-MS) to test the content of organically bound uranium in coal m 1 =7.7mg / kg coal;

[0056] (2) According to the content m of the organically bound uranium in the step (1) 1 , determine the amount of CaO added as m 2 =k 1 m 1 , where k 1 =1.5, that is, 11.55mg CaO is added per kg of coal;

[0057] (3) by attaching figure 1 In the additive addition system, the additive CaO is added to the coal conveying system. The additive and coal are fully mixed in the coal mill and then enter the boiler furnace for combustion. The additive reacts with gaseous uranium in the furnace to form solid CaUO. 4 , these solid-state CaUO 4 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com