Multipoint intelligent cement paste grouting system

A cement slurry, multi-point technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problem of unable to guarantee the pressure balance of synchronous symmetrical grouting and the safety of instruments and meters, and is conducive to quality control and data analysis, realization Fully automatic, avoid uneven pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

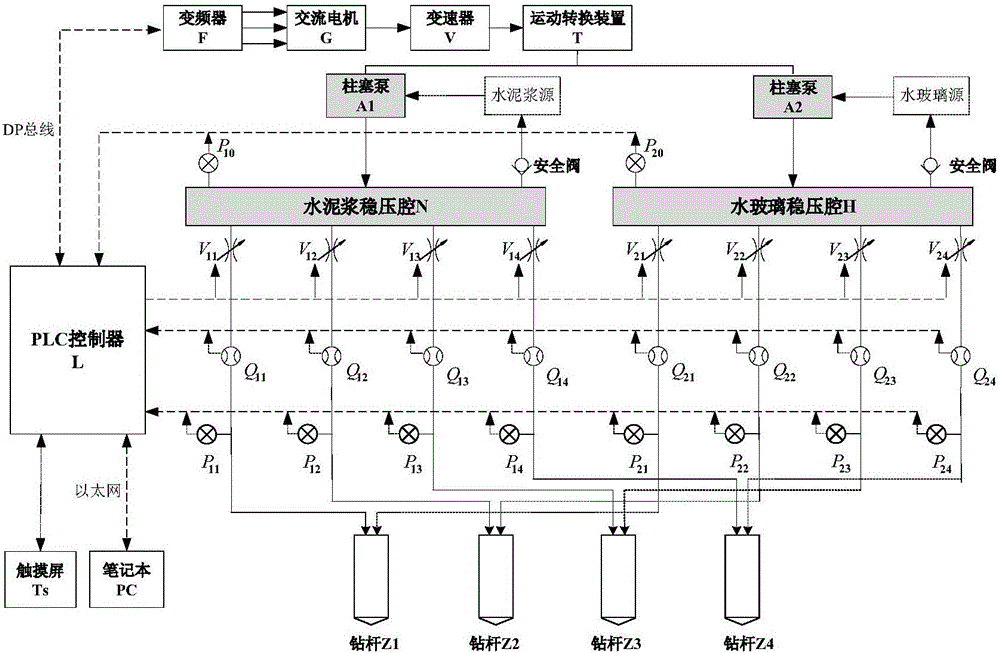

[0040] The structure of the embodiment of the present invention is as figure 1 Shown:

[0041] In the embodiment, a cement slurry multi-point intelligent perfusion system of the present invention is composed of four parts: a control mechanism A, a power mechanism B, an actuator C and a feedback mechanism D:

[0042] Control mechanism A is the control center, responsible for storing programs and data, receiving feedback signals, and sending out control signals; among them, PLC controller L is composed of Si Top DC power supply, DIN rail, PS307, CPU315-2PN / DP, MMC memory card, IM153-1 Kit, bus module PS / IM, bus module IM / IM, 16-way DI / DO module, 4-way AO module, 8-way AI module, 40-pin front connector, 20-pin front connector, Profibus cable, Profibus bus connector And auxiliary original components, the software part is Siemens S7-300 series, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com