Device for measuring internal structure of coke and measuring method thereof

A measurement method, coke technology, applied in the field of iron and steel metallurgy, can solve problems such as misjudgment, fixation, and influence on the accuracy of analysis results, and achieve the effect of accurate measurement results and efficient analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

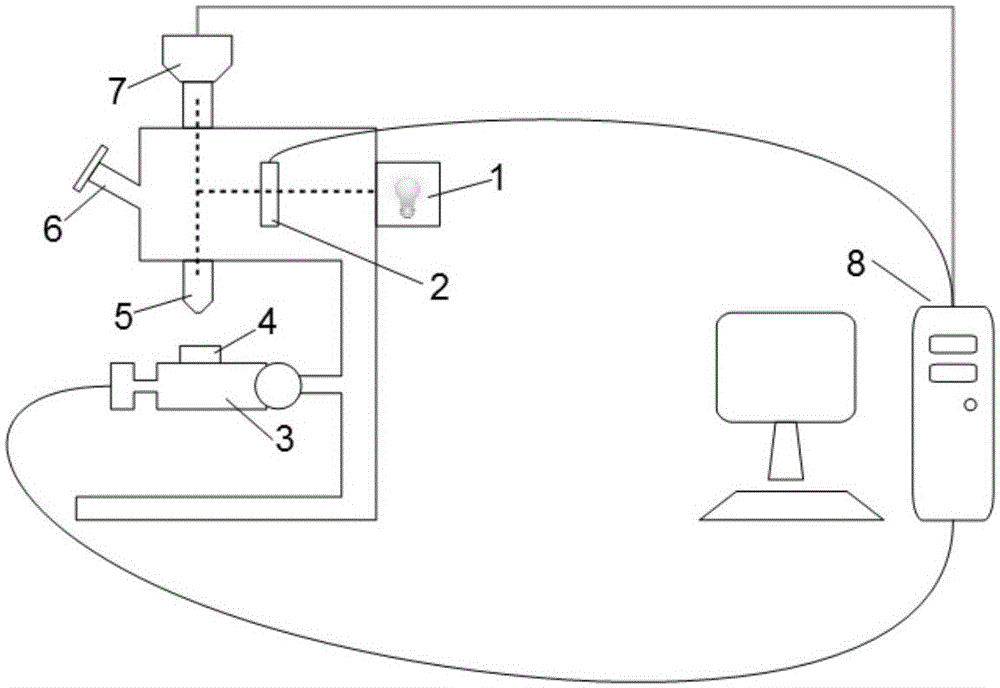

[0049] This embodiment relates to the structure of an automatic measurement and analysis system such as figure 1 As shown, it consists of an automatically controlled optical microscope and a digital image analysis system. When working, the computer 8 controls the polarizer 2 to rotate at a certain angle through the transmission system, thereby converting the natural light incident from the light source 1 into polarized light of different angles. The computer 8 also controls the three-dimensional movement of the stage 3 forward and backward, left and right, and up and down through a series of transmission systems, so as to realize the scanning observation of the surface of the sample 4 to be tested and the automatic focus function when taking pictures. In addition, the microscopic image magnified by the microscope objective lens 5 can not only be photographed by the camera 7 , but also can be directly viewed with the naked eye from the eyepiece 6 .

Embodiment 2

[0051] The present embodiment relates to the automatic measurement and analysis method based on the system of embodiment 1, comprising the following steps:

[0052] 1. After crushing the metallurgical coke, take 4-5g of fine particles with a particle size of 0.071-1mm, and cast them into flakes with a diameter of 22mm with epoxy resin or other cements. The surface of the sample should be polished to meet the requirements of microscope observation. sample light sheet;

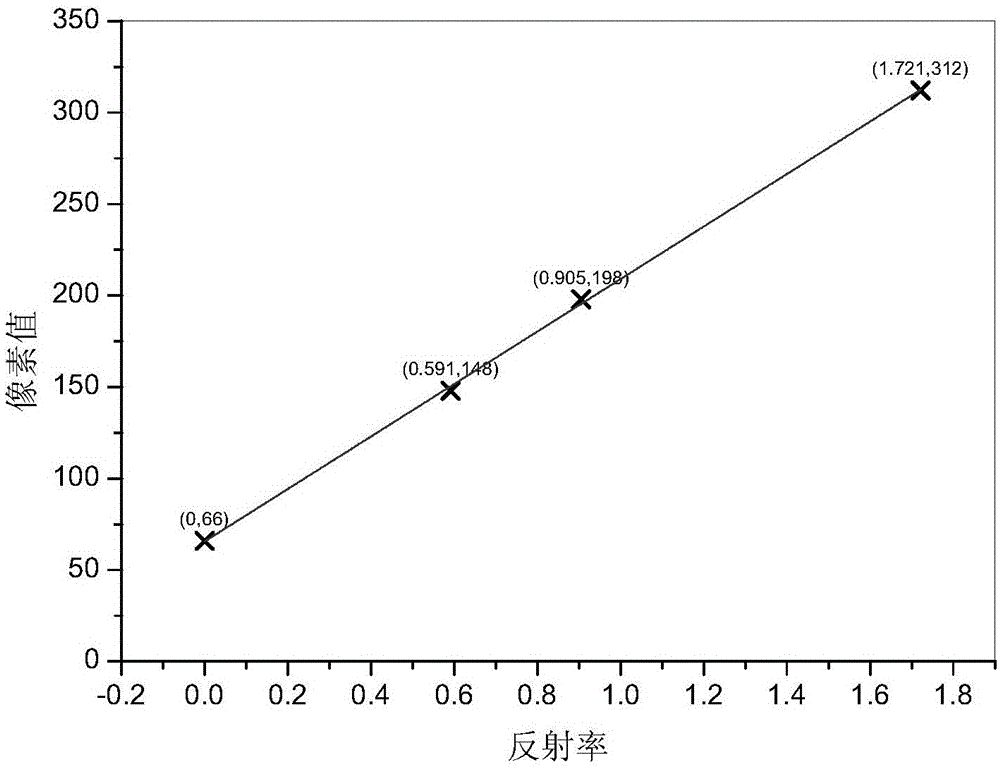

[0053] 2. Use a digital camera to shoot 3 to 4 standard substances with known reflectance under single polarized light, and obtain the corresponding relationship between the pixel value of the digital image and the reflectivity. According to the corresponding relationship, the sample to be tested can be measured The absolute value of the reflectance, such as figure 2 shown;

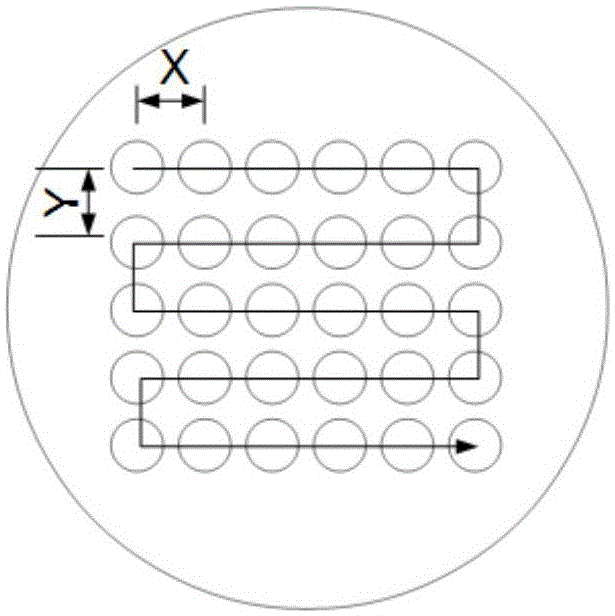

[0054] 3. Place the sample to be tested on the microscope stage and start shooting. Before shooting, set the step length and number of...

Embodiment 3

[0059] Get a certain metallurgical coke powder sample 4g with a particle size less than 1mm, make a light sheet sample with a diameter of 22mm with epoxy resin, and adopt the measurement results of the analytical method in Example 2 as shown in Table 1 and Figure 6-17 Shown:

[0060] Table 1 Automatic analysis results of coke optical structure

[0061] Microcomponent category Proportion(%) Isotropic 49.4 mosaic 23.6

[0062] fibrous 18.0 flaky 7.5 other 1.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com