Piling method in coal yards based on coal petrography and genetic algorithm

A genetic algorithm and coal yard technology, applied in the field of coal yard splitting based on coal petrology and genetic algorithm, can solve the problems such as the simplicity and timeliness of coal yard splitting without consideration, and achieve the effect of speeding up the selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method of coal yard splitting based on coal petrology and genetic algorithm. The concrete steps of this method are:

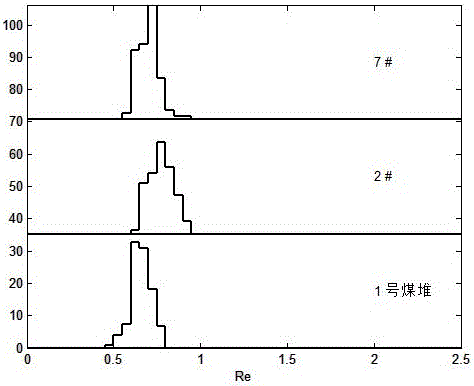

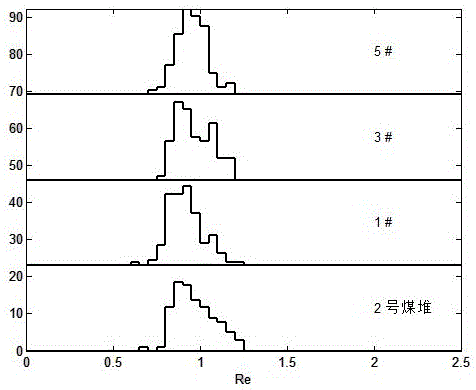

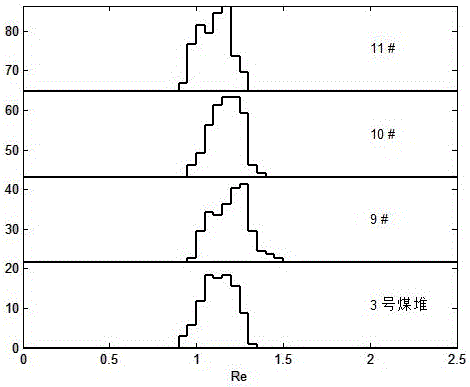

[0048] Step 1. The number M of coal piles in a certain coal yard of the present embodiment is 5, and the number of coal types D is 14. Measure the distribution ratio of vitrinite random reflectance of 5 coal piles in the coal yard and measure 14 kinds The distribution ratio of the vitrinite random reflectance of the incoming coal (due to the complexity of the data on the distribution of the vitrinite random reflectance of the coal, it is not listed), and the coal types of the 14 incoming coals are shown in Table 1.

[0049] Table 1 Coal category of 14 incoming coals

[0050]

[0051] Step 2. Establish the fitness mathematical model Fitness of coal yard sub-pile.

[0052] Fitness=[f 1 ,f 2 ,f 3 ,f 4 ,f 5] (1)

[0053] In formula (1), f i Indicates the coincidence degree of the incoming coal of the i-th coal pile and the vitrinite random refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com