Multilayer segmented built-in permanent magnet synchronous motor used for electric automobile driving

A technology for permanent magnet synchronous motors and electric vehicles, applied in electric vehicles, motors, electromechanical devices, etc., can solve the problems of increasing the risk of irreversible demagnetization of permanent magnets, increasing the eddy current loss of rotor permanent magnets, and increasing the loss of stator cores, etc., to achieve Reduce the risk of irreversible demagnetization, reduce torque ripple and core loss, reduce the effect of core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

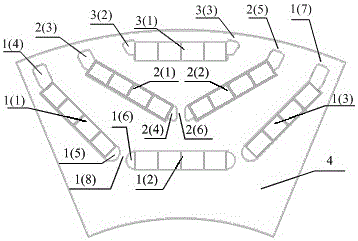

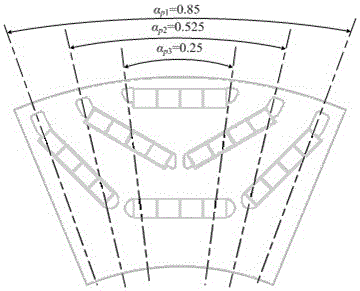

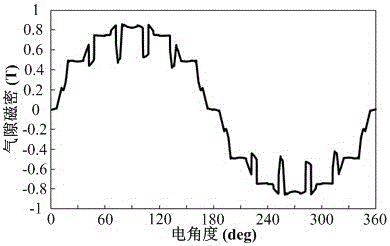

[0017] as attached figure 1 As shown, a multi-layer segmented built-in permanent magnet synchronous motor rotor for electric vehicle drive, the built-in rotor part includes rotor core, three-layer segmented NdFeB magnet and magnetic barrier, it is characterized in that, through optimization The pole arc coefficient of each layer of permanent magnets minimizes the harmonic content of the rotor air gap magnetic density of the interior permanent magnet synchronous motor, thereby reducing the torque ripple and core loss of the interior permanent magnet synchronous motor, and due to the use of multiple layers The mechanism makes the motor salient pole ratio reach more than three, and improves the magnetic field weakening ability of the motor; divides each permanent magnet into 4 sections, reduces the eddy current loss of the permanent magnet, reduces the heat generation of the permanent magnet, improves the ability of resisting irreversible demagnetization, and improves the reliabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com