An online adaptive processing and coating system and its realization method

A self-adapting, coating technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of increasing the manufacturing cost of lamination materials, poor pattern matching, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

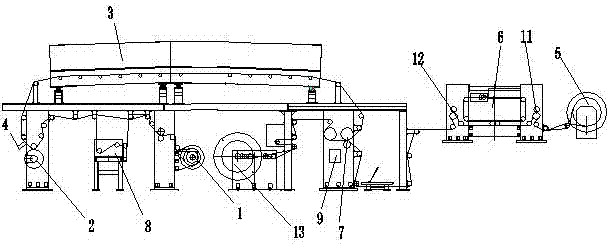

[0018] Such as figure 1 Shown is a specific embodiment of the present invention, and this system comprises the unwinding device I1 of required gluing material, cleaning device 8, gluing device 2, drying device 3, and gluing device 2 is on required gluing material Form the same gluing pattern, set the marking machine 4 for the required gluing material between the gluing device 2 and the drying device 3, and the marking machine 4 will mark I on the required gluing material after gluing,

[0019] It also includes an unwinding device II5 for the required processing material, a processing device 6, a laminating device 7 for two materials, and a detection device 9. The processing device 6 forms a processing pattern corresponding to the glued pattern on the required processing material. 6 The front and rear are respectively provided with an active buffer part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com